Zealous Insights: How Ultrafiltration Systems Boost Water Purity

1. Introduction

In today’s rapidly evolving environmental landscape, ensuring access to clean, safe, and sustainable water is more critical than ever. Ultrafiltration systems have emerged as pivotal technology in water purification, bridging the gap between traditional filtration methods and advanced membrane processes. These systems effectively remove contaminants, pathogens, and suspended solids to meet stringent water quality standards demanded by consumers and industries alike.

The growing awareness of waterborne diseases, coupled with tightening environmental regulations worldwide, has placed ultrafiltration technology at the forefront of water treatment solutions. Backed by decades of research and continuous innovation, companies specializing in membrane filtration have developed sophisticated ultrafiltration systems tailored to diverse applications, combining reliability, efficiency, and environmental sustainability.

2. Application Background and Market Demand Analysis

Across many regions, deteriorating water quality presents significant challenges: contamination from industrial effluents, agricultural runoff, and aging municipal infrastructure compromises potable water safety. For consumers, the demand for pure, safe drinking water is inseparable from health concerns and lifestyle choices favoring sustainability.

Industrial sectors increasingly require advanced treatment processes to comply with environmental standards while maintaining product integrity, especially in pharmaceuticals, food processing, and electronics manufacturing. Additionally, urban municipalities face mounting pressure to adopt cost-effective and energy-efficient technologies to ensure continuous supply without harmful chemical usage.

Consequently, the ultrafiltration systems market is expanding robustly, driven by:

- Heightened public health awareness and stricter water quality regulations

- Growing industrial water treatment needs

- Environmental sustainability commitments and water conservation efforts

3. Technical Principles of Ultrafiltration Systems

At its core, ultrafiltration (UF) employs semipermeable membranes with pore sizes typically ranging from 0.01 to 0.1 microns, enabling retention of suspended solids, bacteria, viruses, and colloidal materials while allowing water and low-molecular-weight solutes to pass through.

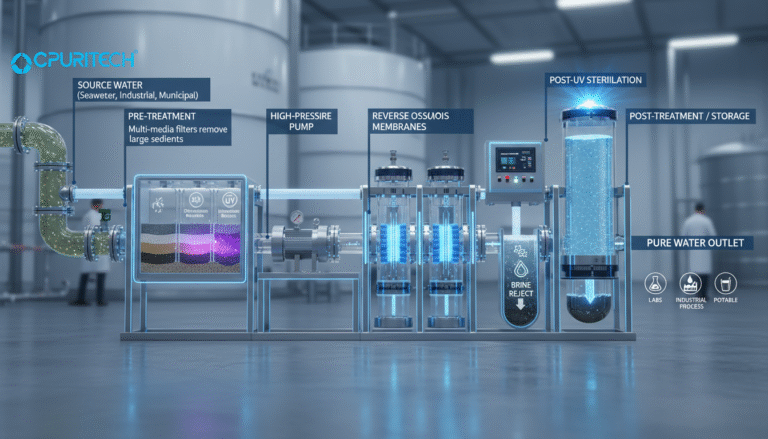

The process works by applying hydraulic pressure to force feedwater through the membrane modules. Key components include:

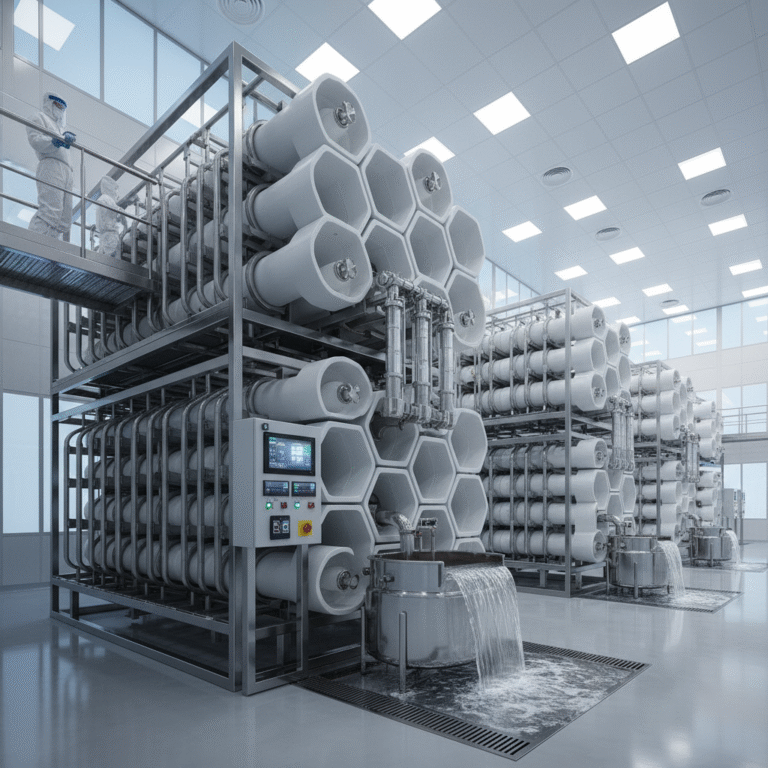

- Membrane modules: Typically hollow fiber or spiral-wound types, designed to maximize surface area for filtration efficiency.

- Feed pump: Supplies necessary pressure, optimized to balance flux and energy consumption.

- Pre-treatment units: Remove larger particles to prolong membrane life and reduce fouling risk.

- Automated control systems: Monitor operation parameters, facilitate backwashing, and enable remote management through IoT integration.

This mechanism effectively removes pathogens and turbidity, delivering water suitable for drinking, industrial processes, or as a pre-treatment step for further purification technologies like reverse osmosis.

4. Industry Evolution and Product Innovation Overview

Leading membrane filtration enterprises have witnessed exponential growth over recent years by combining robust research with market-responsive innovation. Their global footprint includes customized solutions addressing region-specific water challenges—for instance, adapting membrane materials for higher fouling resistance in areas with elevated organic load or implementing modular designs for space-constrained urban plants.

Innovations include the development of polymeric membranes with enhanced permeability and chemical resistance, and the introduction of ultra-high-performance membranes that increase flux rates while reducing energy requirements. Intelligent automation integrated into system controls ensures proactive maintenance and operational optimization.

5. Product Features and Advantages

| Feature | Benefit | Impact |

|---|---|---|

| High-flux membrane technology | Maximizes filtration rate with minimal energy input | Reduces operational costs and carbon footprint |

| Enhanced fouling resistance | Extends membrane lifespan and maintains consistent performance | Lowers maintenance frequency and downtime |

| Smart IoT-enabled monitoring | Enables remote system diagnostics and adaptive control | Improves reliability and response time to anomalies |

| Eco-friendly design | Minimal chemical usage and recyclable membrane components | Supports sustainability goals and regulatory compliance |

Utilizing these system features translates to:

- Health benefits: Reliable removal of pathogens dramatically reduces waterborne illnesses.

- Environmental protection: Low energy operation and reduced chemical dependency minimize ecological impact.

- Economic efficiency: Extended membrane life and smart maintenance decrease lifecycle costs.

6. Multi-Industry Applications and Real-World Experience

In my experience consulting with diverse clients across sectors, ultrafiltration has proved indispensable. For example:

- Hospitality Industry: A chain of hotels implemented UF systems to treat municipal water. Post-installation results showed a 98% reduction in turbidity and microbial contamination, leading to enhanced guest satisfaction and compliance with health regulations.

- Food & Beverage Manufacturing: A beverage producer integrated ultrafiltration systems to recycle process water, achieving a 30% reduction in water consumption and saving over $150,000 annually in wastewater treatment fees.

- Healthcare Facilities: A regional hospital adopted ultrafiltration as pre-treatment for dialysis water. This upgrade ensured ultrapure dialysis fluid, significantly reducing patient infection incidents.

These cases underscore ultrafiltration’s versatility and tangible benefits across applications demanding stringent water purity.

7. Installation and Maintenance Guidelines

Successful deployment of ultrafiltration systems depends on thoughtful planning and rigorous maintenance:

- Installation: Perform site evaluations focusing on feedwater characteristics and spatial constraints; adhere to manufacturer guidelines ensuring appropriate pressure and flow configurations.

- Regular maintenance: Implement scheduled chemical cleaning to combat membrane fouling, leverage automated backwash cycles as part of system design, and continuously monitor performance indicators.

- Local support: Collaborate with regional service teams trained in ultrafiltration technology for rapid troubleshooting and part replacement, ensuring minimal operational disruption.

8. Competitive Landscape and After-Sales Assurance

Compared to conventional filtration techniques such as sand filtration or microfiltration, ultrafiltration offers superior retention of submicron contaminants with far greater reliability. These systems require less footprint than reverse osmosis units while delivering sufficiently purified water for a broad range of uses.

Key differentiators include:

- Higher filtration precision without compromising throughput

- Lower energy demand aligned with modern sustainability imperatives

- Broader chemical compatibility allowing use in diverse industrial contexts

Furthermore, robust product certification aligned with international standards ensures compliance and user confidence. Comprehensive warranties and responsive after-sales service guarantee system longevity and customer satisfaction.

9. User Perceptions and Success Narratives

Feedback collected from end-users has consistently highlighted ultrafiltration’s user-friendliness and performance stability. For example:

“Since installing the ultrafiltration system, we’ve seen a dramatic improvement in water clarity and taste, and our operational costs have dropped significantly.” — Quality Manager, Food Manufacturing Plant

“The automated control interface gives us peace of mind, allowing quick adjustments remotely and ensuring our water treatment runs smoothly 24/7.” — Maintenance Head, Municipal Water Plant

These testimonials reinforce the system’s value proposition and illustrate the trust garnered through proven reliability.

10. Conclusion and Call to Action

In conclusion, advanced ultrafiltration systems represent a transformative leap forward in water purification technology. They effectively address the growing global demand for safe, sustainable, and economically feasible water treatment methods. Leveraging innovations in membrane science and automation, these systems enhance water quality across multiple sectors.

Stakeholders—from municipal authorities to industrial managers—should consider incorporating ultrafiltration into their water treatment portfolios to elevate safety standards and operational efficiency. Given the escalating challenges posed by water scarcity and contamination, investing in ultrafiltration technology today can secure a healthier, more sustainable tomorrow.

References

- Grand View Research – Ultrafiltration Market Size & Share | Industry Report, 2030

- MarketsandMarkets – Hollow Fiber Ultrafiltration Market Forecast Report

- Future Market Insights – Ultrafiltration Membranes Market Size & Forecast 2025-2035

- Research and Markets – Ultrafiltration Membranes Market Size & Forecast to 2029

- Emergen Research – Ultrafiltration Membranes Market Forecast 2021-2030

- Allied Market Research – Membrane Technology Market 2020: Size & Share