Bold Analysis: Is UV Light for Water Treatment the Future for Clean Tech?

The quest for cleaner, safer water supplies has never been more urgent. Among emerging technologies, UV light for water treatment is gaining momentum as a highly effective, chemical-free disinfection method. This article explores the comprehensive landscape of industrial UV water treatment systems, their operational principles, performance metrics, economic considerations, market applications, as well as expert insights from real-world deployments. Our goal is to clarify why this technology is fast becoming a cornerstone of modern clean tech for diverse industries.

1. Product Overview: Types and Applications

UV water treatment equipment broadly encompasses systems designed to disinfect and purify water by exposing it to ultraviolet-C (UV-C) radiation. These devices range from compact units for laboratory or ultra-pure water use to large-scale industrial reactors tailored for municipal wastewater and industrial effluents.

Key industries and water sources adapted for UV treatment include:

- Mining: Treating process water and discharge streams to meet environmental regulations.

- Food Processing: Ensuring microbial safety in water used for washing and ingredient preparation.

- Pharmaceuticals & Cosmetics: Delivering ultrapure water free from pathogens for sensitive formulations.

- Laboratories & Ultra-pure Water Systems: Providing sterile water for research and manufacturing.

- Boiler Feed Water: Minimizing biological fouling to improve thermal efficiency.

- Groundwater, River, and Municipal Water: Safeguarding drinking water quality and wastewater discharge compliance.

This diversity underscores the versatility and growing adoption of UV treatment in both industrial and municipal contexts.

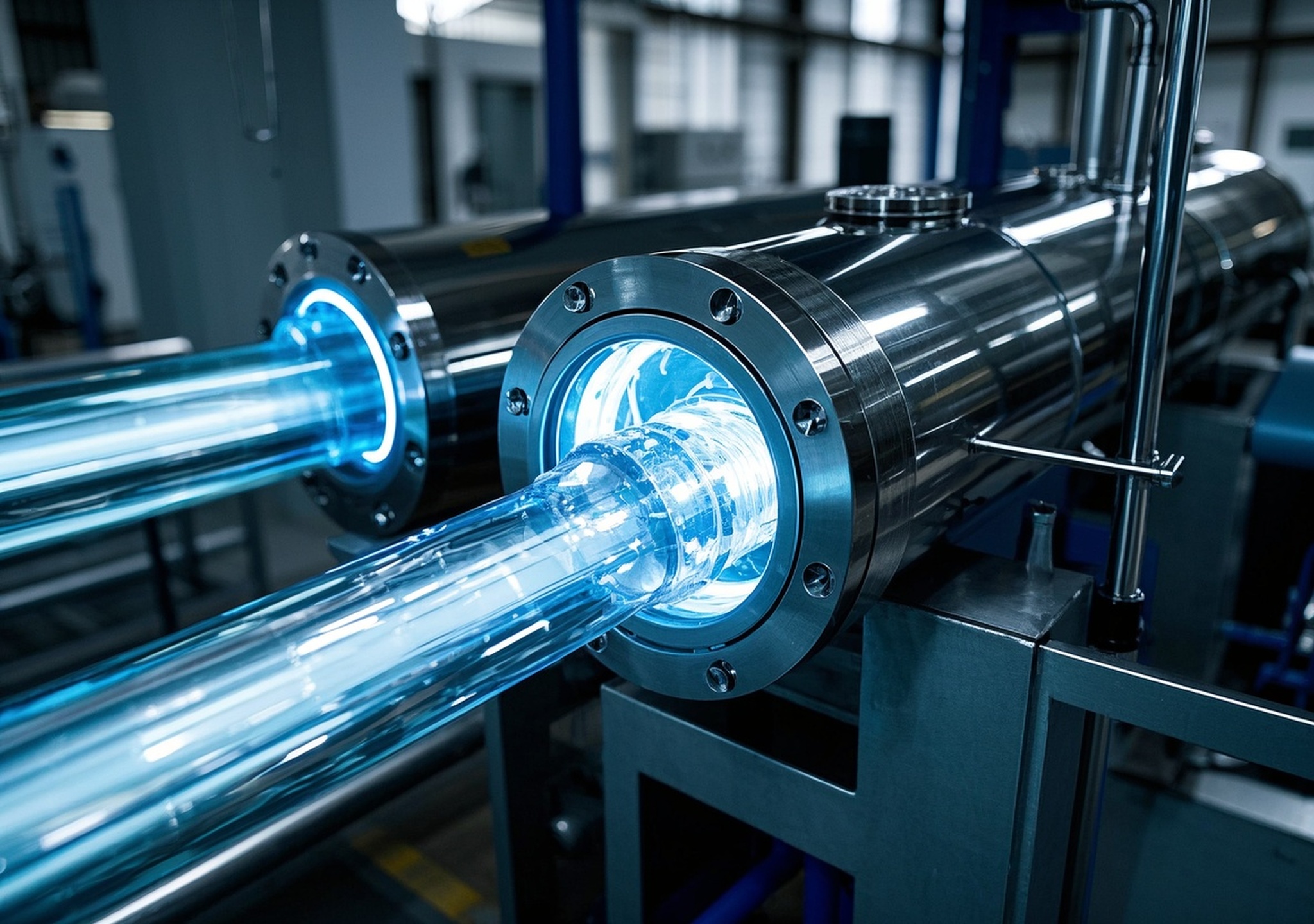

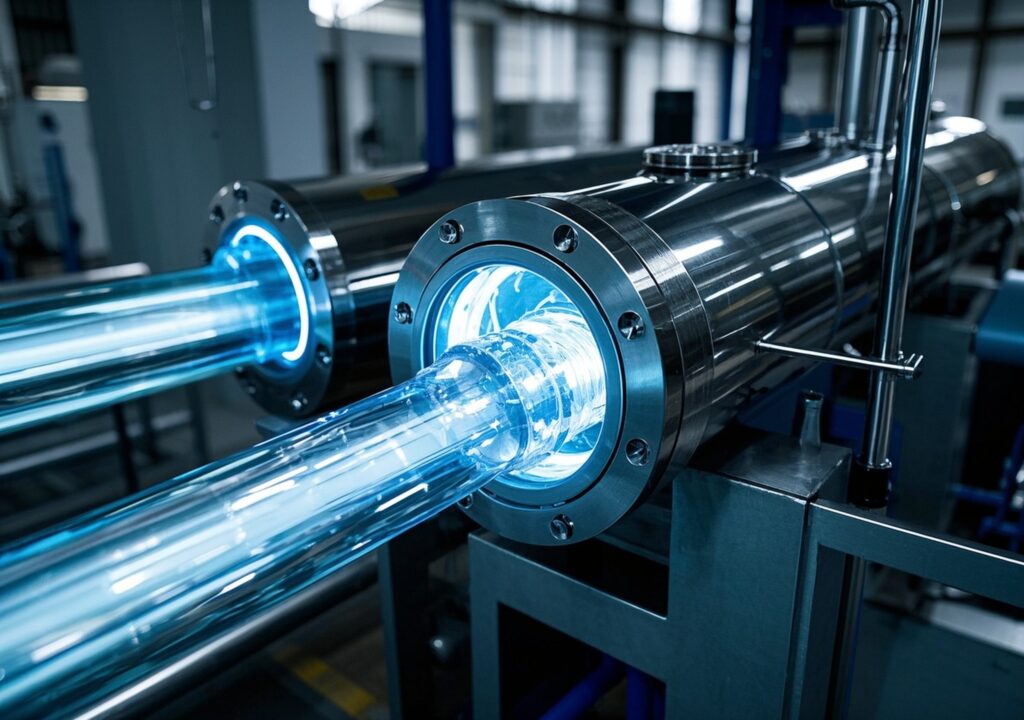

2. Technical Principles and Key Components

The core principle behind UV water treatment lies in the germicidal properties of UV-C light, typically with wavelengths ranging from 200 to 280 nanometers. When water passes through the UV reactor chamber, microorganisms such as bacteria, viruses, and protozoa absorb the radiation. This disrupts their DNA and RNA, rendering them unable to reproduce and effectively inactivating pathogens without chemical additives.

Typical system components include:

- UV Lamps: Low-pressure mercury vapor lamps or advanced LED-UV sources emitting precise UV-C wavelengths.

- Quartz Sleeves: Protective barriers for lamps that ensure optimal UV transmission while resisting corrosion.

- Reactor Chamber: Engineered flow paths designed to maximize UV exposure and contact time.

- Automated Control Units: Real-time monitoring of UV intensity, flow rates, and lamp status to maintain disinfection efficacy.

- Pre-Treatment Modules: Optional filters or screens to remove turbidity and organic matter that may inhibit UV penetration.

The integration of automation and sensor technology enhances operational reliability and allows remote diagnostics, crucial for industrial scaleups.

3. Pricing Analysis: Cost Structure and ROI

Understanding the pricing components of UV water treatment solutions is key for budgeting and long-term investment decisions. The major cost factors include:

| Cost Component | Description | Comments |

|---|---|---|

| Base System | UV lamps, reactors, control units | Core capital expenditure; scales with flow capacity |

| Pre/Post-Treatment Modules | Filtration, sediment removal, chemical dosing (optional) | Needed for water quality ensuring proper UV penetration |

| Installation and Commissioning | Labor, piping, system integration | Typically 10-20% of capital costs depending on complexity |

| Operation & Maintenance (O&M) | Lamp replacements, energy consumption, monitoring | Usually 5-10% of initial cost annually; energy efficiency varies by lamp type |

In my experience managing water treatment projects, the investment in UV systems often pays off within 3-5 years via reduced chemical use, regulatory compliance avoidance costs, and improved water quality. For example, in a recent food processing plant retrofit, switching to UV disinfection cut chemical costs by 60% and reduced downtime related to chemical handling.

4. Performance Specifications and Quality Assurance

Critical performance parameters for industrial UV water treatment include:

- UV Dose: Typically measured in mJ/cm². Effective microbial inactivation usually requires doses between 30-40 mJ/cm².

- Flow Rate Capacity: Customized per application, ranging from 1 m³/hour for lab units to thousands m³/hour for municipal systems.

- Water Turbidity: Must be low (<1 NTU) to avoid UV shielding effects.

- Material Selection: Corrosion-resistant stainless steel or specialized coatings extend service life.

- Certifications: Compliance with international standards such as NSF/ANSI 55 and CE certification ensure verified performance and safety.

Quality control procedures commonly include factory acceptance testing, microbial challenge tests, and in-field validation protocols. These assure customers receive consistent and reliable disinfection performance aligned with regulatory expectations.

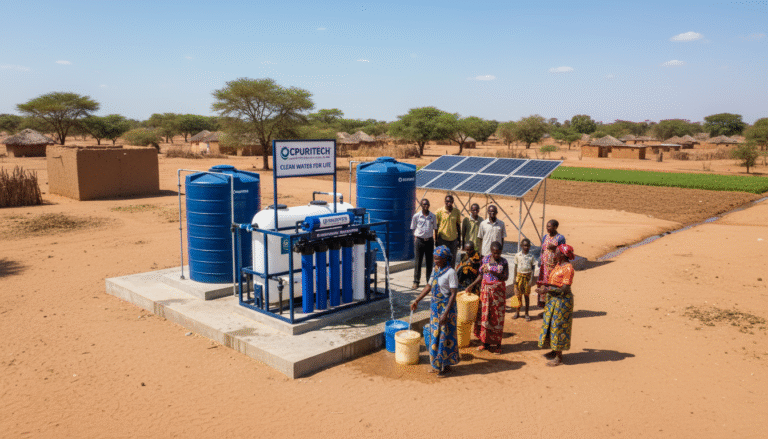

5. Market and Application Scenario Analysis

Global market data paints a promising growth trajectory for UV water treatment technologies. According to Grand View Research, the global UV water treatment systems market was valued at approximately $1.36 billion in 2024 and is forecasted to nearly double to $2.8 billion by 2033, with a compound annual growth rate (CAGR) of 8.4%. Industrial-specific UV disinfection equipment shares this trend, driven by rising demand for efficient pathogen control without chemical residues (Grand View Research – Industrial UV Water Disinfection Equipment Market Size, Growth & Analysis Report, 2033).

Regionally, areas with high waterborne disease prevalence and stringent environmental regulations are leading adopters. For instance, municipalities in North America and Europe prioritize UV for drinking water and wastewater treatment. Commercial sectors such as hospitality and retail are also accelerating uptake due to hygiene awareness post-pandemic.

In regions with challenging water quality, such as areas with high turbidity groundwater, UV systems are often combined with advanced filtration or coagulation pre-treatment to ensure efficacy. This modular adaptability reinforces UV treatment’s role as a versatile and scalable solution.

6. Case Studies: Real-world Deployments

Case 1: Pharmaceutical Water Purification

In a mid-size pharmaceutical manufacturing plant, UV water treatment was integrated as a final disinfection step in the ultrapure water loop. Before UV adoption, microbial contamination incidents impacted batch release schedules by up to 12%. After implementation, microbial counts dropped below detection limits, achieving a 99.99% reduction rate and increasing on-time batch deliveries by 15%. Lamp life was optimized to 9,000 operational hours, reducing maintenance frequency.

Case 2: Municipal Wastewater Reuse

At a municipal water reuse facility in the southwestern U.S., UV treatment was implemented post-secondary treatment to comply with stringent discharge standards. The technology eliminated chlorine usage, thus preventing harmful disinfection byproducts. Treated water met regulatory standards consistently, enabling its use for irrigation and industrial cooling, yielding an annual operational cost saving of 18% compared to past chlorination methods.

Case 3: Food Processing Plant Upgrade

A large-scale food processing site transitioned from chemical sanitizers to a UV-based system for wash water. The switch not only enhanced microbial safety but also simplified regulatory reporting and reduced employee chemical exposure risks. Water treatment uptime improved to 99.5%, with no reported product recalls in the subsequent 24 months.

7. Customized Solutions and Service Support

Leading UV water treatment providers offer tailored systems calibrated to client-specific water quality parameters, flow dynamics, and regulatory compliance needs. Customization options include pre-filtration units, automated cleaning mechanisms for lamp sleeves, and integration with plant monitoring systems for predictive maintenance.

Service support typically encompasses:

- Installation Guidance: On-site engineering support to optimize placement and hydraulic conditions.

- Training: Operator education for routine inspections and troubleshooting.

- Maintenance Contracts: Scheduled lamp replacements, UV intensity verification, and parts inventory management.

- Remote Monitoring: Enabling early fault detection and performance analytics through IoT-enabled controls.

These comprehensive services ensure long-term operational reliability and sustained water safety performance.

8. Manufacturer Profile and Industry Collaboration

UV water treatment system manufacturers invest heavily in R&D, focusing on energy-efficient UV-LED technologies and compact reactor designs that meet diverse industrial needs. Many hold ISO certifications and undergo rigorous third-party performance testing. Collaborations with environmental agencies and academia drive innovation and adherence to evolving standards.

Successful providers emphasize transparent communication, site-specific consulting, and scalability options—crucial for customers navigating complex regulatory landscapes and dynamic water quality challenges.

9. Conclusion and Investment Recommendations

The adoption of UV light for water treatment marks a pivotal evolution in clean technology. Its ability to deliver effective, chemical-free disinfection aligns with global trends favoring sustainability and public health protection. Market data forecasts robust growth driven by industrial and municipal demands, supported by declining costs and technological advancements.

From an investment perspective, UV systems offer compelling returns through operational savings, regulatory risk mitigation, and enhanced water quality outcomes. Critical success factors include selecting appropriately scaled systems, ensuring pretreatment measures are in place, and partnering with providers offering comprehensive lifecycle support.

Given the confluence of regulatory, economic, and environmental drivers, UV light for water treatment stands as a transformative solution and a strategic investment in the future of clean tech.

References

- Grand View Research – Water Treatment Systems Market Size, Share Report 2030

- Grand View Research – Ultraviolet Disinfection Equipment Market Size Report, 2033

- UV Water Treatment Systems Market Size, Growth Research, 2033

- Industrial UV Water Disinfection Equipment Market Size, Growth & Analysis Report – 2033