In the industrial and commercial water treatment landscape, optimizing the performance of a water treatment plant RO system is pivotal for operational efficiency and sustainability. This article delves into the core technologies underpinning modern reverse osmosis (RO) systems, outlines key equipment categories across varying scales, and highlights practical applications. Through insights from longstanding industry experience and authoritative data, we explore how tailored system upgrades can dramatically enhance water purification processes, cost-effectiveness, and regulatory compliance.

Advanced Reverse Osmosis Membrane Systems: Core Technology and Capacities

At the heart of any efficient water treatment plant RO system lies a high-quality membrane module. RO membranes serve as the critical barrier, selectively removing dissolved salts, heavy metals, and emerging contaminants such as PFAS and arsenic. These membranes operate under pressure to facilitate contaminant rejection, producing highly purified water suitable for industrial, commercial, and potable applications.

Modern RO systems come with varying capacities, ranging from small-scale units producing a few hundred liters per hour to large industrial setups exceeding several thousand cubic meters daily. For instance, modular multi-stage RO membranes can be configured to deliver anywhere between 1,000 to 200,000 liters per hour, accommodating diverse needs from food and beverage processing to pharmaceutical ultra-pure water systems.

Compliance with the latest industry standards like NSF/ANSI 58-2023 mandates minimum system recovery rates above 40% and enhanced contaminant reduction, ensuring RO modules meet rigorous performance and sustainability benchmarks.

Filtration, Softening, and Pretreatment Systems: Enhancing RO Longevity and Efficiency

Effective pretreatment is indispensable to protect RO membranes from fouling and scaling, thereby extending membrane life and ensuring steady operational performance. Key technologies include sand filters for particulate removal, activated carbon filters to eliminate chlorine and organic compounds, and water softeners to reduce hardness minerals such as calcium and magnesium.

Pretreatment systems are available in multi-tier configurations tailored to plant capacity, from compact skid-mounted units for commercial applications to fully automated multi-bed softening systems for large water purification plants. Integrating these pretreatment stages reduces RO system downtime and operational costs markedly.

Containerized and Modular RO Systems: Flexibility for Remote and Specialized Deployments

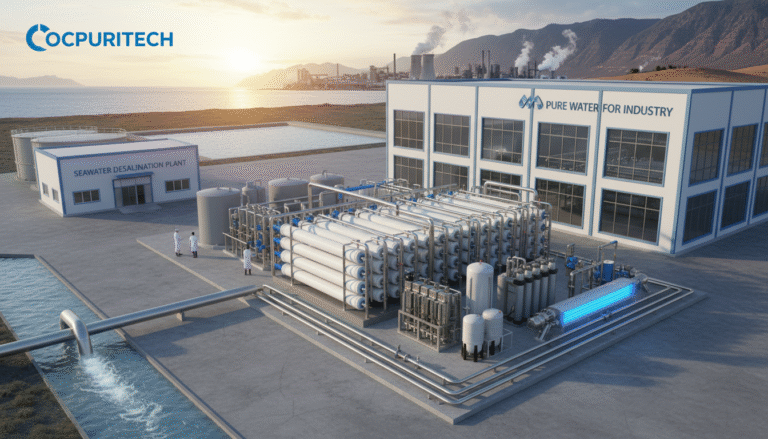

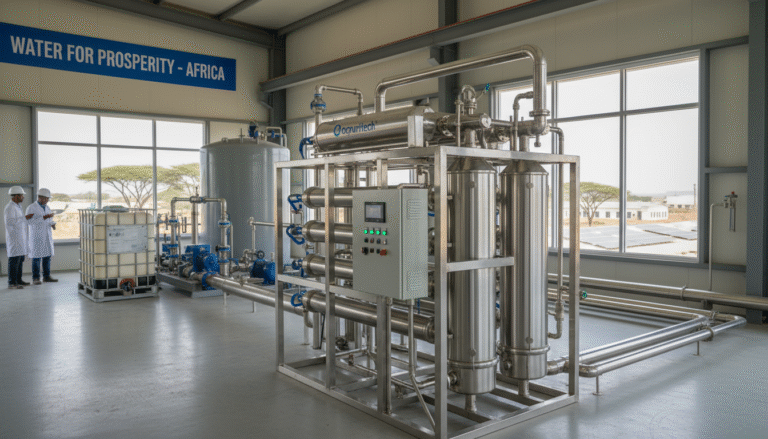

Containerized RO plants have revolutionized water treatment for remote, disaster-stricken, or rapidly deploying sites. These self-contained units combine pretreatment, RO membrane modules, and post-treatment in compact, mobile formats that can be promptly installed without extensive infrastructure.

From my experience working on community water projects in remote areas, containerized solutions offer unparalleled scalability—from units producing a few hundred liters per hour to industrial-grade plants with outputs surpassing 100,000 liters daily. Such versatility supports emergency potable water supply, agricultural irrigation, and even specialized contexts like space mission potable water generation.

The flexibility is underpinned by integrated control systems and real-time monitoring, ensuring compliance with water safety standards and operational efficiency even under unpredictable environmental conditions. This approach aligns with decentralized water treatment solutions gaining global momentum for adaptable, local water purification.

Cleaning and Disinfection Technologies: Ensuring Consistent Water Quality and System Health

Maintaining consistent performance in RO systems necessitates reliable cleaning and disinfection protocols. Ultraviolet (UV) sterilization provides an effective post-treatment step, inactivating microorganisms without chemical residues. This is increasingly relevant for drinking water applications to meet stringent health standards.

Routine chemical cleaning of RO membranes removes fouling deposits, restoring permeability and system recovery. In industrial setups with high organic or biological load, automated clean-in-place (CIP) systems integrated with monitoring ensure membrane longevity and reduce labor costs, reflecting best practices I have implemented in multiple municipal water upgrading projects.

Selecting a Trusted Manufacturer: Quality, Experience, and Innovation

Choosing a reputable water treatment equipment manufacturer is crucial to secure reliable system performance and after-sales support. Established industry players offer comprehensive product lines, including Remote Control Reverse Osmosis Systems, Brackish Water RO Systems, Sea Water Desalination Systems, Ultrafiltration, Nanofiltration, and ultrapure water systems.

In particular, firms operating out of standardized factories with decades of combined experience provide the dual advantage of advanced technology and cost-effective production. Their product portfolios often encompass entire water purification equipment sets, alongside essential spare parts such as filter cartridges, FRP tanks, and flow meters, enabling seamless integration and maintenance.

A manufacturer’s commitment to environmental responsibility is increasingly vital. For example, I have collaborated with companies emphasizing their mission to provide globally accessible clean water while minimizing ecological footprints, which strengthens trust with global clients across Southeast Asia, Africa, and South America.

Diverse Applications Across Industries: From Seawater Desalination to Bottled Water

The versatility of water treatment plant RO systems spans multiple sectors:

- Seawater desalination plants supporting coastal municipalities, transforming saline sources into safe drinking water.

- Commercial bottled water production lines utilizing multisystem filtration for consistent purity and taste.

- Industrial process water treatment for agriculture, dyeing, pharmaceuticals, and semiconductor manufacturing.

- Remote and emergency supply systems, including containerized and portable units deployed in disaster zones or isolated communities.

- Specialized niche applications such as ultrapure water for laboratories and space missions.

In my experience, tailoring system specifications—including membrane type, pretreatment design, and control automation—to industry-specific water quality parameters makes all the difference in achieving operational excellence and compliance.

Conclusion

Upgrading and optimizing water treatment plant RO systems is a strategic investment that enhances efficiency, reduces operational costs, and upholds sustainability goals. Employing advanced membrane technologies, robust pretreatment modules, flexible containerized solutions, and rigorous cleaning protocols ensures a resilient water purification ecosystem adaptable to diverse industrial and commercial demands.

Partnering with experienced manufacturers who prioritize quality, innovation, and environmental responsibility further empowers stakeholders to deliver clean, safe water consistently. As water challenges evolve globally, embracing these upgrades underscores a commitment to both performance and planetary health.

FAQ

Q1: What are the main benefits of upgrading an existing water treatment plant RO system?

Upgrading enhances contaminant removal efficiency, improves water recovery rates, reduces energy consumption, and extends membrane lifespan, leading to lower operating costs and better water quality.

Q2: How does pretreatment impact the performance of a reverse osmosis system?

Pretreatment protects membranes from particulate fouling, chlorine damage, and scaling, ensuring stable flux rates and minimizing downtime for cleaning or replacement.

Q3: What capacity ranges are available for RO systems in industrial settings?

Capacities vary widely, from small commercially sized systems producing a few hundred liters per hour to large-scale plants capable of treating over 200,000 liters daily.

Q4: Are containerized RO systems suitable for emergency water supply?

Yes, their modularity and mobility make them ideal for rapid deployment in disaster zones or remote areas needing immediate potable water solutions.

Q5: How important is compliance with NSF/ANSI 58 standards for RO systems?

Critical for ensuring the system meets recognized contaminant removal efficiency and durability requirements, especially for point-of-use drinking water applications.

Q6: Can RO systems be integrated with other purification technologies?

Absolutely. Typical integrations include ultrafiltration, nanofiltration, UV sterilization, and chemical dosing for comprehensive water treatment.

Q7: What role does UV disinfection play in RO water treatment?

UV provides chemical-free microbial inactivation downstream of RO membranes, ensuring water microbiological safety without residual disinfectants.

Q8: How does system automation improve RO plant operation?

Automation enables real-time monitoring, fault detection, and process optimization, reducing manual intervention and enhancing reliability.

Q9: What are some common industries benefiting from advanced RO water treatment?

Pharmaceutical, beverage, agriculture, hotels, hospital, electronics manufacturing, and municipal water treatment are some of the main beneficiaries.

Q10: How can manufacturers ensure sustainable and eco-friendly water treatment solutions?

By employing energy-efficient membranes, maximizing water recovery, reducing chemical use, and designing systems for longevity and recyclability.