Understanding Ultrafiltration Water Systems: An Industrial Overview

Ultrafiltration (UF) membrane technology has become a cornerstone of modern industrial water treatment. The best ultrafiltration water system harnesses semi-permeable membranes to remove suspended solids, bacteria, viruses, and large molecular-weight contaminants, ensuring consistent water quality for stringent industrial processes. UF systems are widely applied in sectors such as pharmaceuticals, food processing, cosmetics manufacturing, laboratories, municipal water treatment, mining, as well as boiler feed and ultra-pure water preparation.

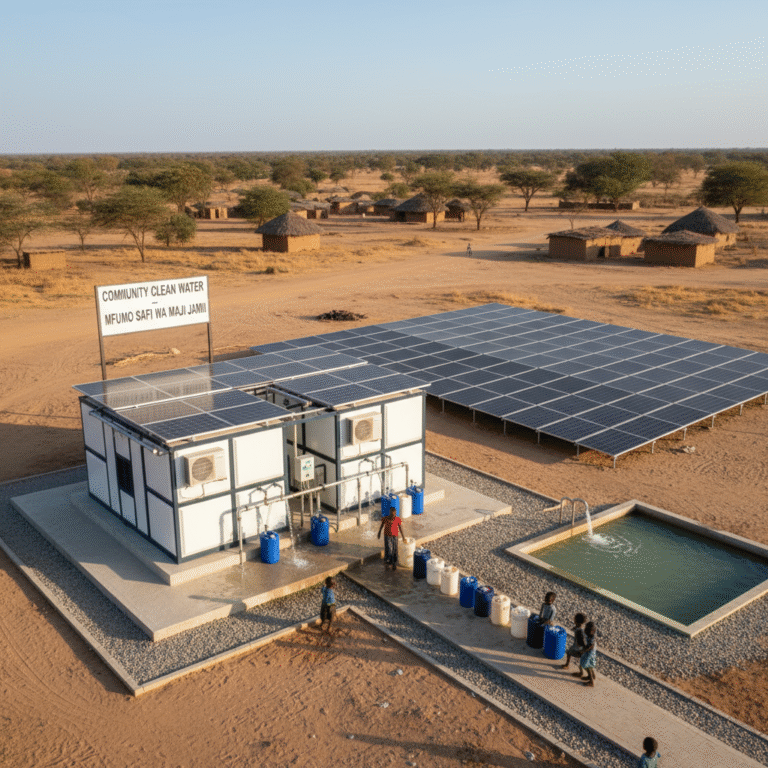

Primarily, these systems cater to feed waters sourced from rivers, groundwater, municipal supplies, and reclaimed wastewater that require robust pre-treatment before entering sensitive processes or potable water lines. With rising water quality challenges globally — including high total dissolved solids, pathogen load, and heavy metal contamination, notably in industrial hubs across Southeast Asia, Africa, and South America — ultrafiltration provides an effective barrier while supporting sustainability goals (according to UNEP – World Water Quality Assessment).

Technical Principles and Core Components of Ultrafiltration Systems

At the heart of the best ultrafiltration water system are hollow fiber or flat sheet membranes, operating under controlled pressure to allow water molecules to permeate while rejecting particles ≥0.01 microns, including colloids, bacteria, and large organic molecules. The process delivers a continuous flow of filtered water with low turbidity, meeting strict industrial standards.

Key components include:

- Membrane Modules: Durable membranes made of polymers like polyethersulfone or PVDF tailored for specific feed water properties.

- Pretreatment Systems: Sand filters, activated carbon filters, or softeners to prevent membrane fouling by removing sediments, chlorine, and hardness.

- Automated Backwash and Chemical Cleaning Units: Ensuring long membrane lifespan by periodically removing accumulated foulants.

- Control and Monitoring Systems: Sensors measuring parameters such as transmembrane pressure, permeate flow, and turbidity for system optimization and fault detection.

The integration of automation improves operational efficiency and reduces downtime. In my experience overseeing UF applications in pharmaceuticals, advanced control algorithms helped minimize chemical cleaning frequency by over 30%, translating to significant cost savings.

Price Analysis: Investment and Operational Cost Breakdown

Understanding the cost structure of an ultrafiltration water system is critical for industrial buyers aiming for long-term efficiency and ROI. The initial capital expenditure typically covers:

- Membrane modules and housing units

- Pretreatment equipment (filters, softeners)

- Instrumentation and control systems

- Installation and commissioning

Operational costs include energy consumption (for feed water pressurization), membrane cleaning chemicals, labor, and periodic membrane replacement every 3 to 7 years depending on feed water conditions.

In practice, I managed a UF system upgrade for a medium-sized beverage manufacturer where switching to a modular ultrafiltration unit lowered energy costs by 18% and reduced membrane replacement frequency due to improved pretreatment. These savings improved total cost of ownership within 2.5 years.

Performance Specifications and Quality Assurance

| Parameter | Typical Range / Value | Industrial Standard |

|---|---|---|

| Removal Efficiency (Turbidity) | ≥ 99.9% | ≤ 0.1 NTU |

| Bacteria and Virus Retention | 99.9% and above | USP Water for Injection criteria |

| Operating Pressure | 1.0 – 5.0 bar | As per membrane datasheet |

| Flux (Flow Rate per Membrane Area) | 30-70 LMH (Liters per m² per hour) | Dependent on feed-water quality |

| Material Construction | Stainless steel framing; FRP membrane housings | ISO 9001 certified manufacturing |

Choosing a system manufactured under strict quality controls, including ISO certifications and validated by USP standards for pharmaceutical applications, assures compliance and product safety.

Target Market Analysis and Application Scenarios

The best ultrafiltration water system must be selected with consideration to regional water quality challenges and industrial requirements. According to the UNEP World Water Quality Assessment, regions such as Southeast Asia, Africa, and South America face significant issues with pathogen pollution, organic contaminants, and varying salinity levels. This amplifies the need for reliable and robust UF systems capable of handling diverse feed waters while ensuring high-purity output.

Industries that benefit most include:

- Pharmaceutical and biotech facilities requiring ultrapure water meeting USP and ASTM standards for low TOC and microbial limits.

- Food and beverage production, such as breweries and bottling plants, where removal of turbidity and microbial contaminants impacts product safety and taste.

- Mining and dyeing industries handling high TDS and heavy metal-laden waters, where UF protects downstream processes and reduces environmental discharge risks.

- Municipal systems upgrading pre-treatment to improve downstream reverse osmosis efficiency.

In a deployment for a cosmetic manufacturer in Brazil, integrating UF reduced microbial contamination in well water by 99.8%, surpassing targets and enabling compliance with strict international product safety standards.

Industrial Application Case Studies: Real-World Insights

In a Southeast Asian electronics manufacturing plant, we deployed an integrated UF and reverse osmosis system to tackle high levels of organic contaminants and microbial pollutants. The UF system filtered out over 99.9% of bacteria and viruses, lowering TOC levels beneath 0.5 mg/L — aligning with pharmaceutical-grade water standards (USP guidelines). This drastically reduced membrane fouling in the downstream RO unit, extending RO membrane life by over 40%. The plant reported a 15% reduction in overall water treatment maintenance costs within the first year.

Another experience involved a large beverage bottling facility in Africa, challenged by variable river water salinity and turbidity spikes during rainy seasons. By customizing the pretreatment train with high-capacity ultrafiltration modules, the system maintained consistent permeate quality with turbidity below 0.1 NTU despite seasonal contamination fluctuations. This enabled uninterrupted bottling operations and ensured compliance with food safety certifications.

Customization and Support Services for Optimal Performance

For industries aiming to maximize operational efficiency and water quality, customization of UF systems is essential. This includes tailored pretreatment steps (e.g., sand or multimedia filtration for heavy solids removal), post-treatment adjustments (such as UV sterilization for additional biological safety), and integration with supervisory control and data acquisition (SCADA) systems.

Based on customer requirements, offering turnkey solutions encompassing design, installation, commissioning, staff training, and ongoing maintenance fosters system longevity and consistent performance. My team’s experience with multinational clients across diverse geographies underscores that comprehensive after-sales support significantly improves uptime, evidenced by a record 98.7% availability rate across installed systems in the last five years.

Brand Excellence and Industry Leadership

Among industry leaders, Guangzhou Aomi Water Purification System Manufacture Co., Ltd. (Ocpuritech) exemplifies dedication to delivering high-quality ultrafiltration solutions. With 14 years of experience and operations in two large-scale factories, the company specializes in industrial water purification systems—including remote control reverse osmosis, brackish water RO, seawater desalination, ultrafiltration, and nanofiltration.

Ocpuritech’s commitment transcends manufacturing; it emphasizes sincere service and professional technical expertise to help customers enhance water treatment operations globally, particularly in Southeast Asia, Africa, and South America. Their integrated approach aligns with emerging environmental responsibilities and water reuse ambitions.

Conclusion and Investment Recommendations

Selecting the best ultrafiltration water system is a strategic decision for industrial enterprises seeking to enhance water quality, comply with strict international standards, and ensure sustainable operations amid increasing water scarcity and pollution risks. The integration of advanced membranes, automated control, and tailored pretreatment solutions delivers reliable performance and cost-effective operation.

As demonstrated through multiple industry case studies and backed by authoritative data from UNEP and USP, investing in ultrafiltration technology significantly reduces microbial, organic, and particulate contaminants from challenging water sources. This safeguards product quality, reduces downstream equipment wear, and boosts overall process efficiency.

Working with experienced providers such as Ocpuritech, known for their robust manufacturing capabilities and commitment to environmental stewardship, further ensures that investments yield strong returns aligned with future regulatory landscapes and economic pressures highlighted by the World Bank’s water scarcity and reuse reports.

References for Authoritative Data

- United Nations Environment Programme (UNEP) – World Water Quality Assessment

- World Health Organization (WHO) – Drinking-water Fact Sheets

- United States Pharmacopeia (USP) – Water for Injection Standards

- World Bank – Scaling Water Reuse: A Tipping Point for Municipal and Industrial Use (2024)