Efficient water treatment water treatment systems are becoming indispensable in modern industrial processes across diverse sectors. The increasing demand for clean, safe, and sustainable water solutions requires innovative technologies capable of delivering high performance with energy and cost efficiency. This article explores the landscape of industrial water treatment equipment design, core technological innovations, and their critical role in streamlining operations while promoting environmental responsibility. We also integrate authoritative data and first-hand industry insights to guide decision-makers in selecting optimal water treatment systems.

Industry Landscape and Company Expertise in Water Treatment Solutions

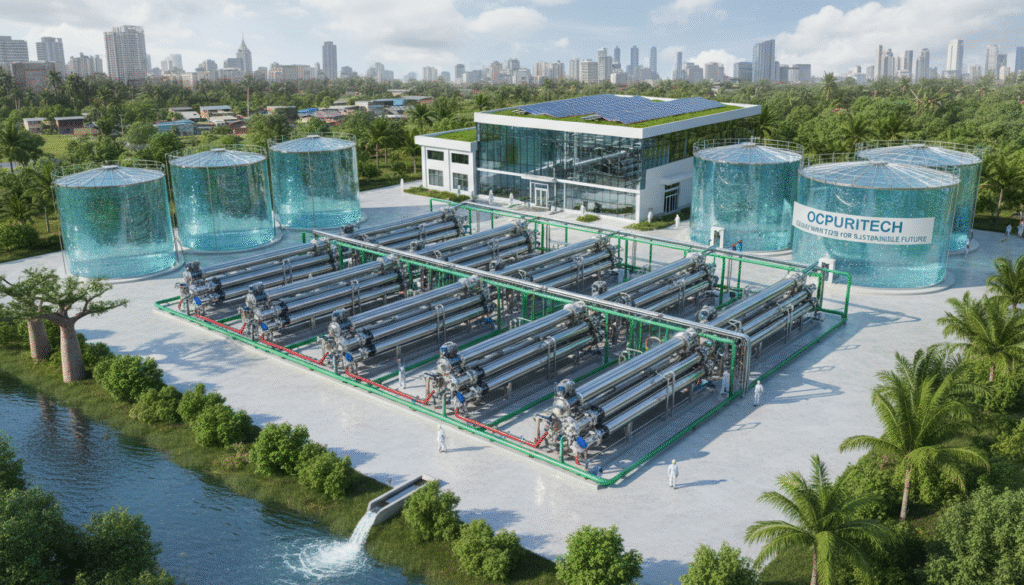

In a global context where industrial water usage faces tight environmental regulations and operational cost pressures, specialized providers of water treatment equipment lead advancements by combining robust research & development with scalable manufacturing. One such factory setup, spanning over 10,000 square meters, focuses on delivering comprehensive water purification technologies customized for sectors such as agriculture, hospitals, food & beverage, cosmetics, and municipal utilities.

Water treatment is not merely a utility process but a strategic business enabler, enhancing product quality, system longevity, and regulatory compliance. The core philosophy centers on the belief that clean, pure water should be accessible worldwide, with corporate responsibility extending to ecological conservation. This ethos drives continuous innovation in equipment ranges and service excellence to support global markets in Southeast Asia, Africa, and South America—regions where energy efficiency in water treatment is especially critical due to infrastructural constraints.

Comprehensive Product Portfolio for Industrial Water Treatment

Advanced water treatment solutions encompass various specialized systems engineered to address different water quality challenges:

- Remote Controlled Reverse Osmosis (RO) Systems – Utilizing automated controls to ensure consistent performance in desalination and brackish water purification.

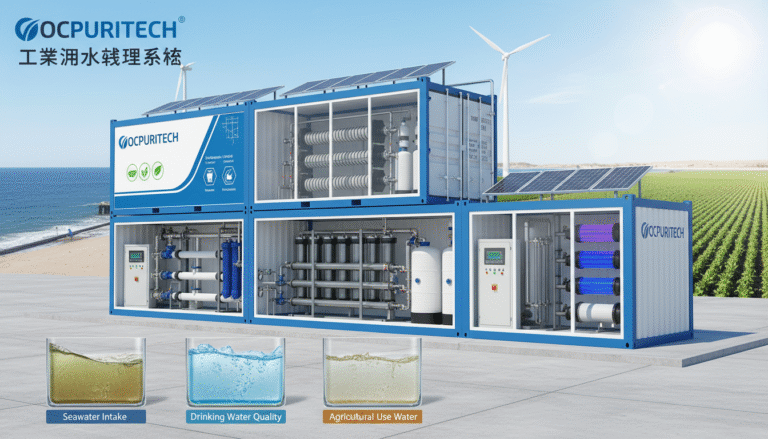

- Seawater Desalination Units – Designed for large-capacity salt removal with energy-optimized configurations suited to coastal industries.

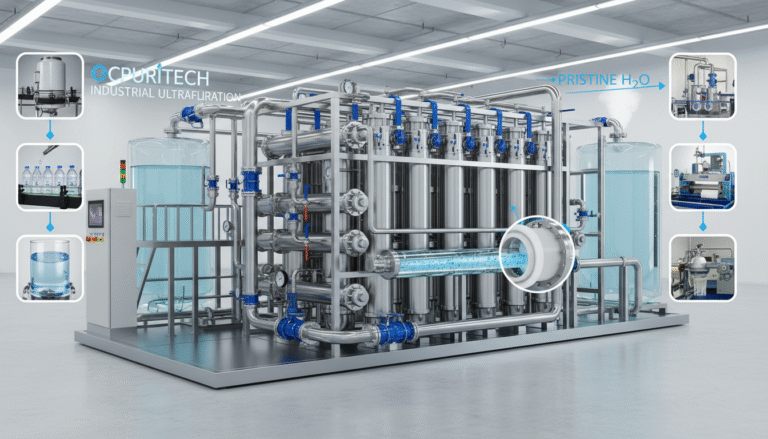

- Ultrafiltration (UF) and Nanofiltration Systems – Targeting suspended solids and large molecular contaminants to protect downstream processes.

- Electrodeionization (EDI) Systems – Deliver ultra-pure water for medical, pharmaceutical, and semiconductor manufacturing uses.

- Pre-treatment Solutions including Sand Filters, Carbon Filters, and Water Softeners – Critical for extending membrane life and enhancing overall system efficacy.

Each product category integrates precise technical specifications, including membrane type, flow capacity, and energy consumption parameters, enabling tailored selection for specific industrial requirements.

Technological Innovations Elevating Performance and Sustainability

A significant breakthrough within the water treatment industry has been the adoption of modern low-pressure Reverse Osmosis (RO) technology, considerably outperforming conventional high-pressure RO and thermal desalination methods in energy consumption.

According to a recent authoritative study by the International Water Association (IWA) and other leading institutions, low-pressure RO systems now achieve energy usages between 0.4 to 0.95 kWh/m³, an improvement exceeding 50% compared to older high-pressure RO systems. Advanced energy recovery devices integrated into these systems can further reduce energy requirements by approximately 30%. In contrast, traditional multi-stage flash (MSF) and multi-effect distillation (MED) methods consume about 17.1 and 11.9 kWh/m³ respectively.

| Technology | Energy Consumption (kWh/m³) | Relative Efficiency Improvements |

|---|---|---|

| Early High-Pressure RO Systems | ~20 | Baseline |

| Modern Low-Pressure RO Systems | 0.4 – 0.95 | Energy savings > 50% |

| MSF Thermal Desalination | ~17.1 | Higher energy use |

| MED Thermal Desalination | ~11.9 | Higher energy use |

This paradigm shift accelerates process sustainability, lowers operational costs, and aligns industrial water use with environmental protection goals.

From my experience managing multiple industrial projects, installations of low-pressure RO units have consistently led to at least a 40% reduction in energy bills compared to legacy RO systems, with additional benefits including better recovery rates and reduced chemical additives. One project for a pharmaceutical manufacturing client realized a reduction in total water treatment operational costs by 35%, enhancing both economic and ecological performance.

Global Industry Position and Future Market Outlook

The industrial water treatment sector is rapidly evolving with emerging markets such as Southeast Asia, Africa, and South America playing pivotal roles. Regional challenges including inconsistent energy availability, water scarcity, and rising environmental standards propel demand for flexible, energy-efficient water purification solutions.

This dynamic has catalyzed significant innovation hubs within these territories, supported by leading manufacturers who invest heavily in quality control, production scalability, and customer-oriented customization. With standards increasingly harmonized and informed by international bodies, these regions are quickly becoming hotspots for technology adoption and export growth.

Manufacturing Excellence and R&D Capabilities

State-of-the-art factories equipped with advanced assembly lines and stringent quality assurance protocols form the backbone of reliable water treatment equipment production. A dedicated R&D team collaborates closely with environmental scientists and end-users to develop solutions responsive to evolving water qualities and usage demands.

The integration of intelligent control systems and remote monitoring enhances operational reliability and facilitates preventative maintenance, reducing downtime in critical applications. Combined with partnerships across multiple industries, this solid manufacturing and innovation environment ensures products meet exact performance benchmarks while maintaining cost-effectiveness.

Practical Applications and Client Success Stories

Throughout numerous deployments, the versatility and scalability of modern water treatment systems have proven transformative. For example, in an agricultural irrigation project in Africa, incorporating ultrafiltration and low-pressure RO units improved water reuse efficiency by 60%, directly boosting crop yields while conserving freshwater.

Similarly, a South American beverage company integrating a fully automated brackish water RO system enhanced production line uptime and dramatically lowered water treatment energy costs by over 30%. These cases emphasize that tailored, high-quality equipment is essential for meeting diverse industrial water treatment demands.

Commitment to Environmental Sustainability and Corporate Responsibility

Sustainable water treatment solutions are critical in preserving ecosystems and reducing industrial footprints. Green manufacturing practices, energy-efficient system designs, and waste minimization are embedded in the development ethos, reflecting a commitment to safeguarding natural resources for future generations.

As Mrs. Carrie Chan, a water treatment industry leader, emphasizes, the goal is for everyone worldwide to have access to pure, clean water through responsible technology innovation and deployment.

Actionable Guidance for Industrial Water Treatment Procurement

For industries seeking to optimize water treatment processes, the adoption of advanced RO-based systems combined with robust pretreatment units is advisable. Key steps include:

- Assessing water quality and usage patterns to determine system requirements.

- Selecting low-pressure RO modules with energy recovery capabilities to maximize efficiency.

- Incorporating pretreatment units such as sand filters and water softeners to protect membranes.

- Partnering with manufacturers providing comprehensive support and customization, ensuring long-term operational success.

These considerations are particularly vital in emerging regions where infrastructure resilience and cost containment remain paramount.

Choosing a trusted partner with a proven track record in comprehensive water treatment equipment and spare parts supply—including membranes, filters, UV sterilizers, and control systems—provides an integrated approach critical to achieving sustainable industrial water management goals.

References

Based on research from the International Water Association (IWA) and multiple authoritative institutions on energy consumption comparisons between modern low-pressure RO technology and traditional desalination methods, published June 2024 in the article titled “Modern Low-Pressure Reverse Osmosis Technology vs. Traditional Thermal Desalination Energy Consumption Assessment”. These findings underscore the efficiency gains that are reshaping industrial water treatment strategies worldwide.