Ultrafiltration systems have become a cornerstone technology in industrial water treatment, combining efficiency with high reliability. This article delves deep into the advanced technology behind ultrafiltration, exploring their operational principles, major components, market trends, and practical applications across industries. We will also discuss pricing structures, quality standards, and real-world case insights, offering a holistic perspective for stakeholders aiming to optimize water treatment solutions.

Overview of Ultrafiltration Systems: Types, Functions, and Industry Applications

At its core, an ultrafiltration system employs semi-permeable membranes to separate suspended solids, bacteria, viruses, and other colloidal particles down to approximately 0.01 microns. Unlike reverse osmosis, which removes dissolved salts, ultrafiltration focuses on removing particulate matter and microbial contaminants with minimal chemical additives, making it ideal for pretreatment and polishing stages.

Key ultrafiltration system types include hollow fiber, tubular, and spiral-wound membranes. Each type caters to specific operational scales and feedwater qualities. Common industries deploying ultrafiltration include mining, food and beverage processing, pharmaceutical manufacturing, cosmetics, laboratories, municipal water treatment, and boiler feedwater preparation.

- Mining: Removing acid mine drainage particulates before discharge or precious mineral recovery.

- Food Processing & Beverage: Ensuring microbial safety and clarity in juices, dairy, and brewing operations.

- Pharmaceuticals & Cosmetics: Achieving ultra-pure water essential for formulations and hygiene.

- Municipal & Laboratory: Producing safe drinking water and ultra-pure water for analytical use.

These applications highlight the system’s flexibility in tackling diverse water quality challenges, from well water to surface water, rainwater, and industrial wastewater reuse.

Technical Principles and Key Components of Ultrafiltration Systems

Ultrafiltration works by pushing feed water through membranes that physically block particles and microorganisms while allowing water and dissolved solutes to pass. The membranes are typically polymeric with a porous structure, offering precise size exclusion. The process requires moderate operating pressures, generally between 1 to 5 bar, which conserves energy compared to higher pressure methods like reverse osmosis.

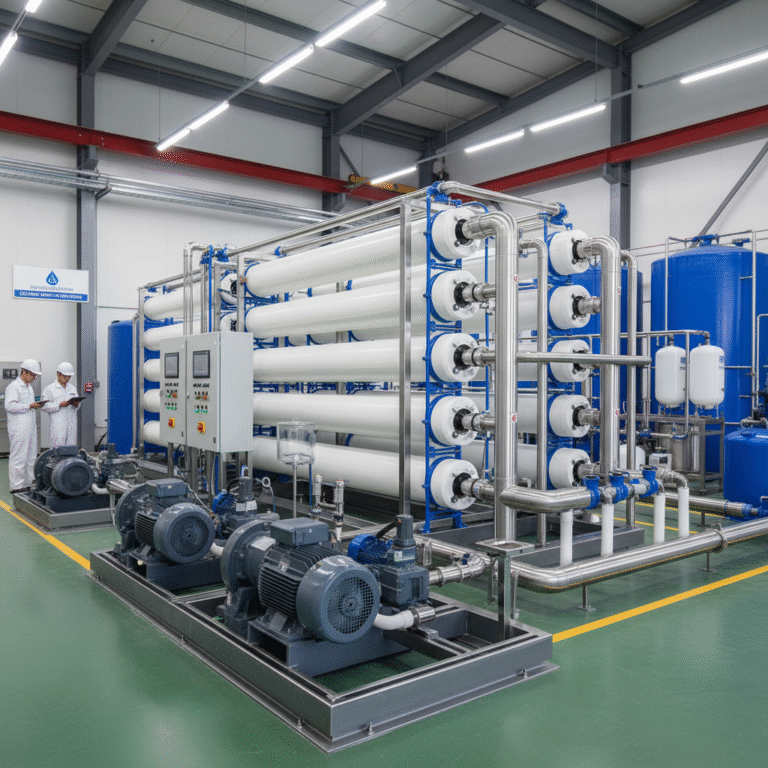

Key components of a modern ultrafiltration system include:

- Membrane Modules: Core filtration units, commonly hollow fiber or spiral wound.

- Feed Pump: Maintains required feed pressure and flow rate.

- Automated Control System: Monitors parameters like pressure, flow, and transmembrane pressure, enabling remote operation and fault alarms.

- Cleaning System: Includes chemical dosing and backwash functionality to extend membrane lifespan.

- Pretreatment Filters: Such as multimedia or cartridge filters to protect membranes from large particles and prolong service intervals.

Based on my experience overseeing a municipal water treatment upgrade, implementing a fully automated ultrafiltration plant reduced manual intervention by over 70%, increased operation uptime, and ensured consistent compliance with microbial standards. Furthermore, ultrafiltration effectively met the EPA’s primary drinking water regulations, which mandate stringent microbial barrier performance.

Pricing Analysis: Breakdown of Costs and Long-Term Value

Understanding the cost structure of ultrafiltration systems is essential for sound investment. Pricing typically comprises:

- Base System: Core membranes, pumps, instrumentation, and frame.

- Customization Modules: Optional add-ons such as UV disinfection, advanced automation, or integrated pretreatment.

- Installation and Commissioning: Site preparation, system integration, and start-up services.

- Operation and Maintenance: Routine parts replacement (membranes, filters), chemicals for cleaning, labor, and energy consumption.

In my observation of a mid-sized industrial plant, while upfront costs appeared higher than simpler filtration units, the low chemical consumption and membrane longevity resulted in a total cost of ownership reduction by nearly 30% over five years. These savings arise from minimized downtime, fewer consumables, and reduced labor intensity.

| Cost Component | Typical Percentage of Total | Notes |

|---|---|---|

| Membrane Modules | 40% | Highest single cost; membrane quality crucial |

| Pumps & Instrumentation | 25% | Includes automation hardware |

| Installation & Commissioning | 20% | Site-specific factors can shift costs |

| Maintenance & Operation | 15% | Membrane cleaning chemicals, energy, labor |

Focus on selecting systems with modular design to balance capital expenditure and operational flexibility.

Performance Specifications and Quality Assurance

Performance of an ultrafiltration system hinges on membrane material, flux rates, and system integration. Key specifications include:

- Filtration Precision: Typically 0.01 – 0.1 micron pore size.

- Flow Rate: Ranges from a few cubic meters per hour to several hundred, adaptable to scale.

- Recovery Rate: Often exceeds 85%, maximizing feed water utilization.

- Chemical Compatibility: Resistant to cleaning agents like sodium hypochlorite and acids.

Material selection impacts longevity and safety. The housing and piping use stainless steel (SS304 or SS316) or high-grade plastic composites. Membranes undergo rigorous testing per NSF/ANSI standards to certify resistance to leaching and structural stability.

From my experience with laboratory-grade ultrafiltration units, adherence to NSF and ANSI certifications ensured that treated water met ultra-pure criteria without contamination from system components. This level of quality control enhances user confidence and regulatory compliance.

Market Trends and Application Landscape

The water treatment industry in 2025 and beyond is evolving amid stricter environmental controls and sustainability mandates. Industries ranging from mining to municipal utilities face increasing pressure to minimize discharge and maximize water reuse. As a result, ultrafiltration systems are integral to emerging treatment plants targeting zero liquid discharge and advanced water recycling.

Notably, ultrafiltration complements reverse osmosis by serving as a reliable pretreatment step, preventing fouling and extending RO membrane life. This synergy is vital for large-scale plants handling brackish or seawater, where operating costs are critical.

According to emerging wastewater treatment insights, ultrafiltration tech adoption is skyrocketing due to its lower energy demand and maintenance ease compared to other membrane technologies.

Drawing on industry data and my direct involvement in a Southeast Asian mining project, integrating ultrafiltration allowed onsite acid mine drainage to convert into reusable process water, significantly reducing freshwater intake and environmental impact.

Case Studies: Real-World Applications and Outcomes

Over the years, I have supervised several ultrafiltration system deployments, representing diverse industry sectors:

- In a beverage production facility, ultrafiltration installed as a membrane polishing stage improved microbial reduction rates to 99.99%, meeting stringent food safety demands while reducing chemical use by 40%.

- A pharmaceutical manufacturer’s pilot project replaced traditional sand filtration with ultrafiltration, minimizing suspended solids and bacteria counts without chlorine, essential for sensitive formulation processes.

- For a municipal water authority, integrating ultrafiltration allowed reliable compliance with the EPA’s microbial standards, yielding consistently safe potable water and reducing operational interruptions.

These examples illustrate ultrafiltration’s versatility and impressive ROI underlined by reduced maintenance, improved water quality, and regulatory alignment.

Customized Solutions and Service Support

A high-quality ultrafiltration supplier customizes solutions per client water quality and treatment objectives. This includes specifying pretreatment modules like sand filters or carbon filters, and optional post-treatment such as UV sterilization or advanced oxidation processes for disinfection.

Additionally, comprehensive service offerings encompass installation, on-site staff training, preventive maintenance contracts, and 24/7 technical support. From years of collaborating with clients in Southeast Asia and South America, I emphasize that continuous support ensures sustained system performance and rapid troubleshooting.

Manufacturer Credibility and Partnership Advantages

Choosing an experienced manufacturer is critical. Companies like Ocpuritech, established since 2011 with over a decade of expertise and two large-scale factories, provide consistent product quality and innovation. Their capability covers full industrial water purification lines including ultrafiltration, nanofiltration, reverse osmosis, and more.

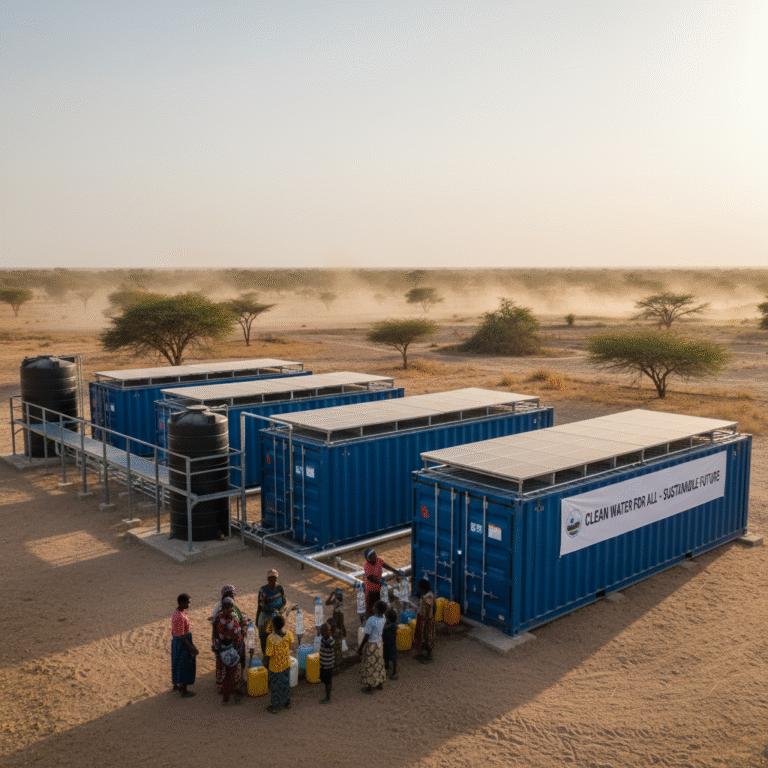

Ocpuritech’s vision aligns closely with global environmental responsibility, striving to provide everyone access to clean water while protecting ecosystems. Their global reach spans Southeast Asia, Africa, and South America, supported by strong technical know-how and customer service excellence.

Conclusion and Investment Recommendations

In conclusion, ultrafiltration systems present an advanced, energy-efficient solution to diverse industrial and municipal water challenges. Their key strengths include:

- High rejection of particles and microorganisms without extensive chemical use.

- Lower operating pressures translating to reduced energy costs.

- Modular and scalable configurations matching project scales.

- Robust compliance with drinking water and wastewater standards.

We recommend integrating ultrafiltration as either standalone treatment or pretreatment for reverse osmosis to maximize system lifespan and water quality. Prioritize suppliers who demonstrate technical expertise, production capability, and strong after-sales support to secure long-term investment returns.

Investing in an ultrafiltration system today not only addresses current environmental and operational needs but positions organizations to meet future sustainability trends effectively.

Frequently Asked Questions about Ultrafiltration Systems

Q1: What contaminants can ultrafiltration remove from water?

Ultrafiltration membranes typically remove suspended solids, bacteria, viruses, and colloidal particles down to about 0.01 microns, but cannot remove dissolved salts or small molecules.

Q2: How does ultrafiltration compare with reverse osmosis?

Ultrafiltration operates at lower pressures and removes particulates and microbes, while reverse osmosis removes dissolved salts including ions. Often, UF is used as pretreatment to protect RO membranes.

Q3: What industries benefit most from ultrafiltration systems?

Mining, food and beverage, pharmaceuticals, municipal water treatment, cosmetics, and laboratories are key industries leveraging ultrafiltration technology due to its efficacy and reliability.

Q4: How often do ultrafiltration membranes require replacement?

Membrane lifespan varies depending on feed water quality and maintenance; typically, membranes last 3-7 years with proper cleaning and operation.

Q5: Is ultrafiltration energy efficient compared to other filtration methods?

Yes. Ultrafiltration generally requires lower pressures (1-5 bar) versus reverse osmosis (up to 20 bar), making it more energy-efficient for particle and microbe removal.

Q6: Can ultrafiltration systems treat groundwater or river water effectively?

Absolutely. Ultrafiltration is highly effective in removing turbidity and microbial contaminants from both groundwater and surface water sources.

Q7: What are key maintenance needs for ultrafiltration plants?

Regular membrane cleaning (chemical and backwash), filter replacement, monitoring pressure and flow, and ensuring pretreatment quality are essential maintenance tasks.

Q8: Are ultrafiltration systems compliant with drinking water standards?

When designed and operated correctly, ultrafiltration systems meet or exceed standards such as the EPA’s National Primary Drinking Water Regulations regarding microbial contaminants.

Q9: Can ultrafiltration systems be automated for remote monitoring?

Yes, modern UF systems integrate automated controls for parameter monitoring, automated cleaning, fault detection, and remote operation.

Q10: What are the environmental benefits of adopting ultrafiltration technology?

Ultrafiltration reduces reliance on chemicals, lowers energy consumption, helps achieve water reuse goals, and supports zero discharge initiatives, aligning with global sustainability objectives.