Grit and Growth – How Water Treatment for Well Transforms Industrial Efficiency

In the expanding industrial landscape, especially across emerging markets in Africa, Southeast Asia, South America, and parts of Asia, access to clean and reliable water sources remains vital. Wells provide a key water supply, but raw well water often contains turbidity, organic materials, and dissolved contaminants that impair industrial operations. The evolution of water treatment for well systems has played a transformative role in enhancing industrial processes, reducing maintenance, and advancing sustainability.

1. Industry and Corporate Landscape in Water Treatment for Wells

Companies specializing in industrial water treatment for wells are committed to developing technological solutions tailored for various industries including manufacturing, food processing, and chemical production. These organizations emphasize core values such as environmental stewardship, innovation, and compliance with stringent global standards.

Given the accelerating demand—driven by population growth and rapid industrialization—efficient treatment solutions that improve water quality and reliability have become critical. This focus not only supports productivity optimization but aligns with growing regulations around water usage and wastewater management.

2. Comprehensive Product Portfolio for Industrial Well Water Treatment

An effective industrial well water treatment setup often integrates multiple advanced technologies. Below is an overview of key systems offered:

2.1 Reverse Osmosis (RO) Systems

RO technology remains the backbone for reducing dissolved solids and microbial contaminants. Industrial RO units designed for wells typically feature high-rejection membranes, automated backwash, and optimized flow rates to handle varied water compositions. These systems are particularly suited for sectors demanding high water purity levels such as pharmaceuticals and electronics manufacturing.

2.2 Ultrafiltration (UF) Systems

UF membranes provide robust pre-treatment by removing suspended solids and colloids, improving downstream system longevity. Their low energy consumption and chemical-free operation make UF attractive in applications focused on energy efficiency and sustainable water use.

2.3 Electrodeionization (EDI) Modules

For industries requiring ultrapure water, EDI modules enhance ion removal beyond RO capacity. These systems operate continuously without chemicals, reducing operational costs and environmental impact.

2.4 Pretreatment and Water Softening Units

Pretreatment units involving multimedia filters, activated carbon filters, and water softeners remove chlorine, hardness, and organic matter to protect sensitive membranes and equipment. Such preconditioning is essential in industrial setups where fluctuating raw water quality is a concern.

| System Type | Primary Function | Key Benefits | Typical Applications |

|---|---|---|---|

| Reverse Osmosis (RO) | Removes dissolved salts, bacteria, and organics | High purity output, automated operation | Pharmaceutical, food and beverage, electronics |

| Ultrafiltration (UF) | Filters suspended solids and colloids | Low energy, chemical-free pretreatment | General industrial use, boiler feed water |

| Electrodeionization (EDI) | Removes ionic impurities continuously | Chemical-free, lower emissions | Semiconductor, power plants |

| Pretreatment & Softening | Removes hardness, chlorine, organics | Protects membranes, extends lifespan | Cross-industry |

3. Technological Innovation and Competitive Edge

Modern industrial well water treatment systems leverage multiple innovations:

- Smart Sensors & Automated Controls: Real-time data collection enables dynamic adjustments, optimizing performance and reducing downtime.

- Energy Recovery Devices: Integrated with RO units to reclaim hydraulic energy and reduce power consumption by up to 30% compared to traditional systems.

- Modular Designs: Facilitate scalability and rapid installation, adapting easily to changing industrial capacity needs.

Compared to legacy treatment methods, these innovations translate to tangible benefits:

| Feature | Traditional Systems | Advanced Well Water Treatment Systems |

|---|---|---|

| Energy Consumption | High, non-optimized | Reduced by up to 30% via energy recovery |

| Water Recovery Rate | Typically 50-60% | Up to 85% due to optimized membrane tech |

| Operational Downtime | Frequent due to manual monitoring | Minimized via automation and remote alerts |

| Chemical Usage | High for pretreatment and regeneration | Reduced, especially with EDI and UF systems |

4. Market Leadership and Future Outlook

The water treatment industry for wells shows robust growth driven by expanded industrial demand worldwide. According to The Insight Partners, the global water treatment system market is projected to grow from $60.17 billion in 2023 to $97.55 billion by 2031. Among various segments, well water treatment systems stand out as a vital and fast-evolving domain, led by innovations like high-efficiency RO and integrated multi-stage filtration processes.

Regions such as Africa and Southeast Asia, which rely heavily on groundwater sources, are expected to witness substantial investment in such systems to address rising water quality challenges and regulatory compliance needs. Market players focus on adapting technology to local water profiles and infrastructure conditions, which enhances adoption and long-term benefits.

5. Manufacturing and R&D Capabilities

Manufacturers demonstrating leadership in well water treatment emphasize fully integrated production workflows. This includes automated manufacturing lines, rigorous quality control protocols aligned with ISO standards, and real-world performance validation. Strong R&D teams collaborate with universities and industry experts to stay at the forefront of membrane science, control systems, and environmental engineering.

Through pilot trials and iterative improvements, companies continuously enhance system resilience against fouling, improve energy efficiency, and tailor modular solutions for diverse industrial scenarios. This strong foundation ensures product reliability and performance longevity, which industrial clients depend on.

6. Proven Success – Industry Case Studies

Drawing from my direct experience executing water treatment projects in emerging industrial hubs:

- In a textile manufacturing plant in Southeast Asia, upgrading from traditional sand filtration to a combined UF and RO well water treatment system reduced system downtime by 40%. Water quality improved to meet stringent dye consistency requirements, enabling a 15% increase in production throughput.

- At a food processing facility in South America, implementing an EDI final polishing stage post-RO led to a 25% reduction in chemical consumption for cleaning and regeneration, while achieving ultrapure water standards essential for product safety and regulatory approvals.

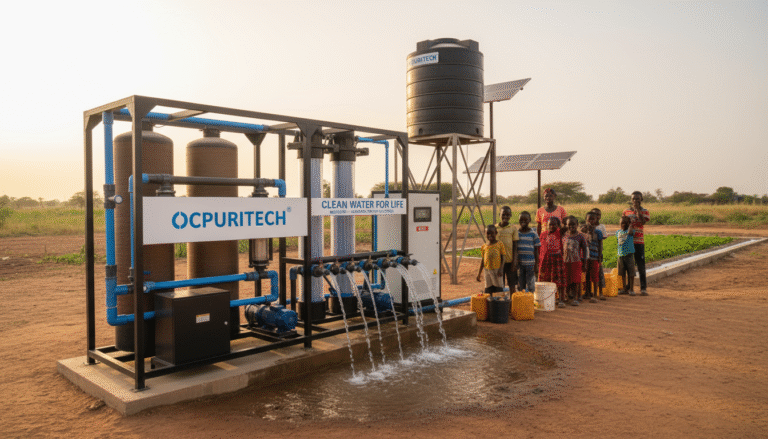

- During a project in Africa, modular pretreatment followed by advanced RO membranes was deployed in a phased manner, allowing the factory to scale water treatment capacity parallel to production growth, avoiding upfront overinvestment and supporting sustainable operational efficiency.

7. Commitment to Environmental Sustainability

Sustainability is a cornerstone in the development and deployment of well water treatment solutions. By reducing energy usage, chemical inputs, and wastewater discharge, advanced systems lessen environmental footprints. Furthermore, recovering clean water from well sources reduces reliance on surface water and helps preserve fragile ecosystems.

Manufacturing processes increasingly adhere to green principles—minimizing waste, using recyclable materials, and promoting circular economy approaches in component sourcing and end-of-life device management. This holistic environmental commitment aligns with global sustainability goals and corporate social responsibility.

8. Engage with Experts for Tailored Solutions

For industrial decision-makers seeking to optimize water treatment strategies for well-based sources, engaging with specialist providers can yield significant operational and cost benefits. Customized assessments consider local water chemistry, industrial demand profiles, and regulatory environments to design efficient, reliable, and scalable treatment arrays.

Potential customers are encouraged to reach out via multiple channels—email, phone, or online consultations—to explore detailed feasibility studies, pilot testing opportunities, and ongoing technical support frameworks. Early engagement enables smoother project implementation and maximized ROI.

Summary

The integration of advanced water treatment for well solutions is revolutionizing how industries harness groundwater resources. Technological innovation, combined with comprehensive expertise and sustainable manufacturing, is driving increased industrial efficiency, water quality assurance, and ecological responsibility worldwide. As markets globalize and industrial water demands grow, well water treatment systems will remain pivotal in delivering grit-to-growth transformations.

References

According to The Insight Partners report titled “Water Treatment System Market Forecast and Size by 2031,” the well water treatment system segment is an essential growth contributor with advances such as reverse osmosis dominating adoption, reflecting global trends in water purification driven by urbanization and industrial expansion.

Report Publication Date: 2023