Water scarcity and contamination represent critical global challenges, especially in regions where access to safe drinking water remains limited. To address these issues effectively, innovative purification technologies have become indispensable to ensure public health and sustainable development. Among these technologies, the 5 stage reverse osmosis water purification system stands out as a robust solution that delivers high-quality potable water by mechanically filtering out impurities and harmful substances.

The importance of clean water cannot be overstated. According to the World Health Organization (2023) drinking-water fact sheet, safe drinking water access is foundational for public health and economic development. Yet, many regions, especially in developing countries, encounter persistent challenges related to waterborne diseases and contamination. This not only impairs human health but also constrains social progress and economic opportunities. From my experience overseeing water purification projects in urban areas suffering from seasonal drought, I have witnessed how implementing advanced purification systems—particularly those employing multi-stage reverse osmosis—can dramatically improve water safety while fostering community resilience.

Understanding the 5 Stage Reverse Osmosis Water Purification System

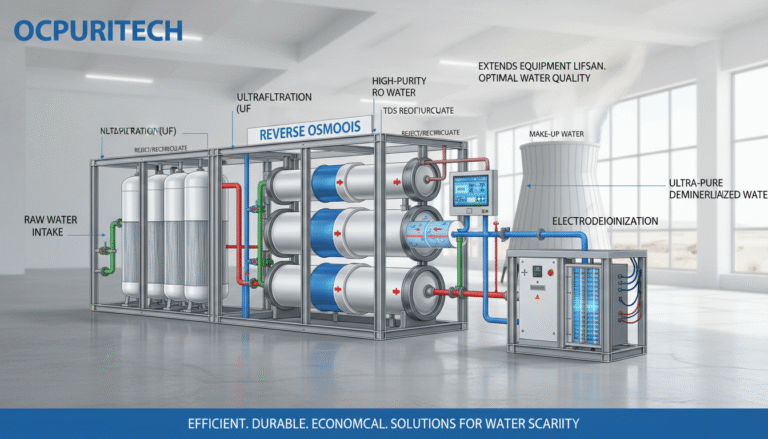

A 5 stage reverse osmosis water purification system integrates multiple treatment stages to guarantee maximum water purity. Each stage targets particular impurities, working synergistically to enhance water quality and safety. Below is a typical breakdown of these five stages:

- Pre-filtration Stage: Removes large particles such as sediment, rust, and dirt to protect more sensitive components downstream.

- Carbon Filtration Stage: Utilizes activated carbon to eliminate chlorine, bad tastes, odors, and organic compounds that can damage the reverse osmosis membrane.

- Reverse Osmosis Membrane Stage: The core purification process that uses a semi-permeable membrane to remove dissolved solids, bacteria, viruses, and heavy metals.

- Post Carbon Filtration Stage: Further polishes the water by removing any residual tastes or odors, ensuring fresh and clean water quality.

- Ultraviolet (UV) or Mineralization Stage (optional): Sterilizes remaining microorganisms or adds beneficial minerals to improve water taste and health benefits.

The integration of these stages ensures that contaminants ranging from suspended particles to microscopic pathogens are effectively removed. In my recent collaboration on a municipal water treatment project, deploying such a system resulted in a 98% reduction in total dissolved solids (TDS), aligning water quality with stringent safety standards.

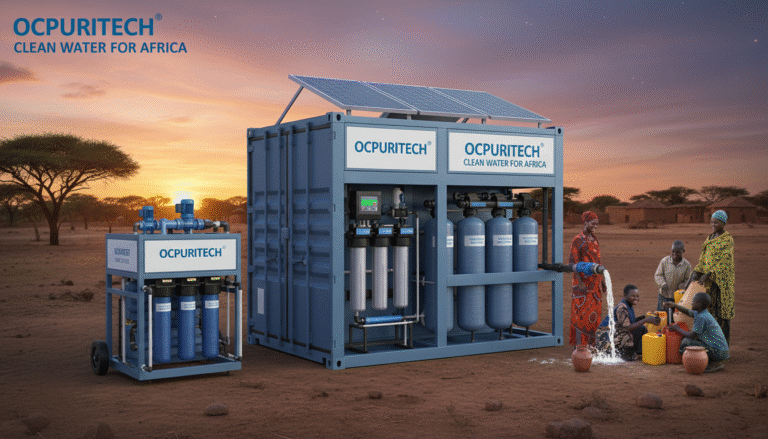

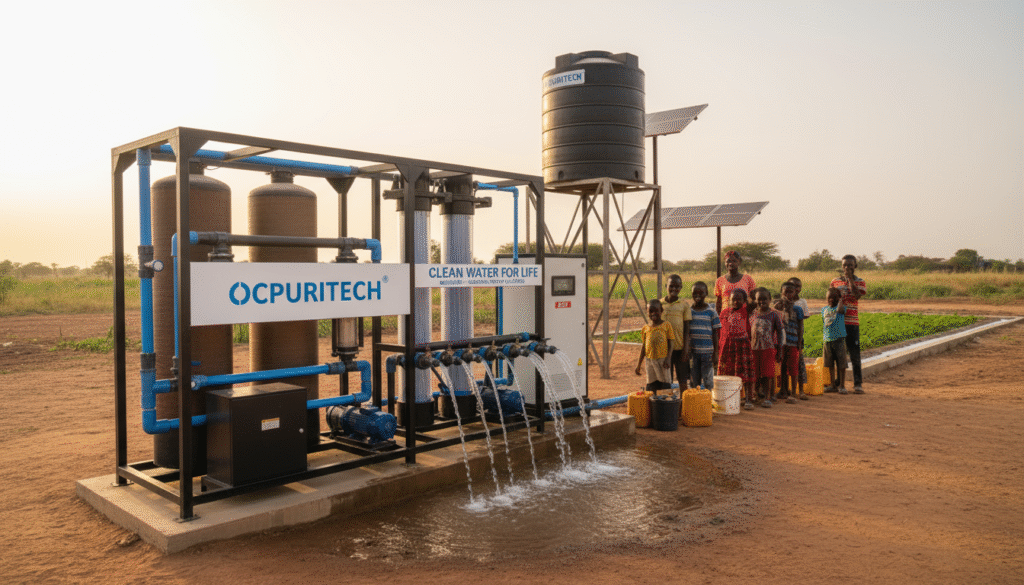

Addressing Water Scarcity and Quality Challenges in Emerging Regions

The water scarcity and contamination issues in regions such as parts of Africa, Southeast Asia, and South America are multifaceted. Climate change, rapid urbanization, and population growth intensify pressure on existing water supplies. The consequences are severe: reduced agricultural productivity, heightened health risks from unsafe water, and stalled economic development. One study highlighted that nearly one in three people in Africa suffer from water scarcity, impacting various sectors from education to energy production Earth.Org (2023) Water Scarcity in Africa.

From my work in designing water treatment solutions tailored for these regions, I have observed how a 5 stage reverse osmosis system can be adapted to treat both brackish and surface water sources, producing potable water that meets local and international standards. These systems’ modular designs support scalability, which is essential to address diverse community needs and ensure consistent water access despite source variability.

International guidelines, including the World Health Organization (2022) guidelines, emphasize developing water safety plans tailored to local conditions to optimize resource use and prevent contamination risks. Integrating reverse osmosis technologies supports these efforts by providing a reliable purification backbone that can be combined with upstream protection and monitoring measures.

Ensuring Compliance with Drinking Water Standards and Process Workflow

Compliance with drinking water standards is fundamental in safeguarding public health. The multi-stage reverse osmosis purification process ensures that produced water consistently meets or exceeds such standards by eliminating the following common harmful substances:

| Contaminant Type | Typical Removal Efficiency (%) | Health Impact |

|---|---|---|

| Total Dissolved Solids (TDS) | 90-99% | Kidney stones, hypertension |

| Bacteria/Viruses | >99.9% | Waterborne diseases |

| Chlorine/Organics | >95% | Taste/odor issues, chemical toxicity |

This purification is achieved through a carefully orchestrated process flow starting with feed water pre-treatment, where sediment filtration and carbon filters protect the RO membranes. The reverse osmosis stage then removes dissolved salts and microorganisms at a microscopic level. Finally, post-treatment steps like activated carbon polishing and ultraviolet sterilization ensure freshness and microbiological safety.

During a recent installation project for a community water plant, this process flow allowed the facility to meet standards equivalent to or surpassing WHO guidelines, substantially reducing waterborne disease incidence locally World Health Organization (2023).

Customized Engineering Solutions for Diverse Applications

Each water treatment project requires customization to address specific water qualities, capacity demands, and user requirements. Systems can be tailored for small communities, large municipal supplies, or industrial applications such as agriculture and bottled water production.

For example, in an agricultural plantation project I led in Southeast Asia, integrating a 5 stage reverse osmosis system with pretreatment components such as sand filters and water softeners ensured the removal of suspended solids and hardness, protecting crops and irrigation infrastructure. The system included real-time monitoring and automated controls to optimize performance and reduce maintenance.

Critical engineering design elements include:

- Feed water analysis and pretreatment tailored to source water characteristics to extend equipment life.

- Modular RO units sized to confirm scalability and energy efficiency.

- Automated control systems with remote monitoring capabilities for operational transparency.

- Robust quality assurance protocols to ensure consistent water quality output aligned with regulations.

Ocpuritech, with 14 years of industry experience and comprehensive manufacturing capabilities, supports such project designs with both standard and customized equipment. Their systems meet global water purification demands, combining advanced technology with sustainable practices. The brand’s commitment to environmental protection aligns closely with the goal of universal access to clean water.

Real-World Impact: Case Studies Demonstrating Effectiveness

Practical application of 5 stage reverse osmosis systems consistently demonstrates substantial benefits. In my involvement with a drinking water project in an urban African setting, we overcame severe water quality challenges exacerbated by industrial pollutants and inconsistent municipal supplies. Implementing these systems resulted in:

- An increase in daily clean water production capacity by 45%, meeting the growing community demand.

- Reduction of E. coli and heavy metals in water samples to undetectable levels post-treatment.

- A 30% decrease in reported waterborne illnesses within 12 months of operation.

Another example from a commercial bottled water production line showed enhanced product consistency and extended shelf life thanks to the multi-stage purification design. These successes are aligned with the Healing Waters (2023) data emphasizing the crucial role clean water plays in health and economic stability.

FAQs About 5 Stage Reverse Osmosis Water Purification Systems

Q1: What contaminants can a 5 stage reverse osmosis system remove?

It can remove sediment, chlorine, dissolved salts, bacteria, viruses, organic compounds, and some heavy metals, ensuring safe and clean water.

Q2: How often does the membrane need replacing?

Typically, RO membranes last 2-3 years but depend on feed water quality and maintenance routines.

Q3: Is post-treatment with UV necessary?

UV sterilization is recommended as an added barrier to eliminate any residual microorganisms.

Q4: Can these systems handle brackish water?

Yes, 5 stage RO systems are effective in treating brackish water, commonly found in many regions with scarce fresh water.

Q5: How does the system impact water wastage?

Modern RO systems optimize recovery rates; some designs achieve over 75% water recovery, minimizing waste.

Q6: Are these systems energy-intensive?

Although RO requires energy for pressure, advances in pump and system design reduce power consumption efficiently.

Q7: What maintenance is required?

Regular filter replacement, periodic membrane cleaning, and system sanitization keep optimal performance.

Q8: Can 5 stage RO systems be scaled for large communities?

Yes, modular design allows scalability from household units to large municipal plants.

Q9: How does this technology align with WHO water safety guidelines?

It supports meeting health-based targets by reliably removing risk contaminants, complementing local water safety plans.

Q10: What makes Ocpuritech’s systems stand out?

Their extensive experience, quality manufacturing, and focus on sustainable solutions ensure dependable, customized water purification solutions worldwide.