In the rapidly accelerating process of global industrialization, access to quality water resources and the efficiency of their utilization have become pivotal for enterprise sustainability and operational cost control. Whether it’s manufacturing, agriculture, or daily drinking water supply, the demand for high-quality, high-efficiency water treatment solutions is constantly growing. At Ocpuritech, with 14 years of industry experience as a water purification system manufacturer, we are dedicated to providing innovative and reliable water treatment solutions to address global water challenges. As our founder, Mrs. Carrie Chan, states, “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.” This profound commitment underscores our mission.

Advanced water treatment plant machinery plays a core role in boosting industrial production efficiency, reducing operational costs, and meeting increasingly stringent environmental regulations. This article will delve into the types of industrial water treatment equipment, technical principles, cost structures, performance advantages, application scenarios, successful case studies, and how Ocpuritech provides customized solutions and excellent service to our clients.

I. Product Overview: Types, Functions, and Applicable Industries of Ocpuritech Industrial Water Treatment Equipment

At Ocpuritech, our expertise lies in delivering comprehensive industrial water purification solutions. Our core product lines are designed to meet diverse needs, offering both standard and remotely controlled systems to ensure operational flexibility and efficiency.

A. Core Business and Equipment Classification

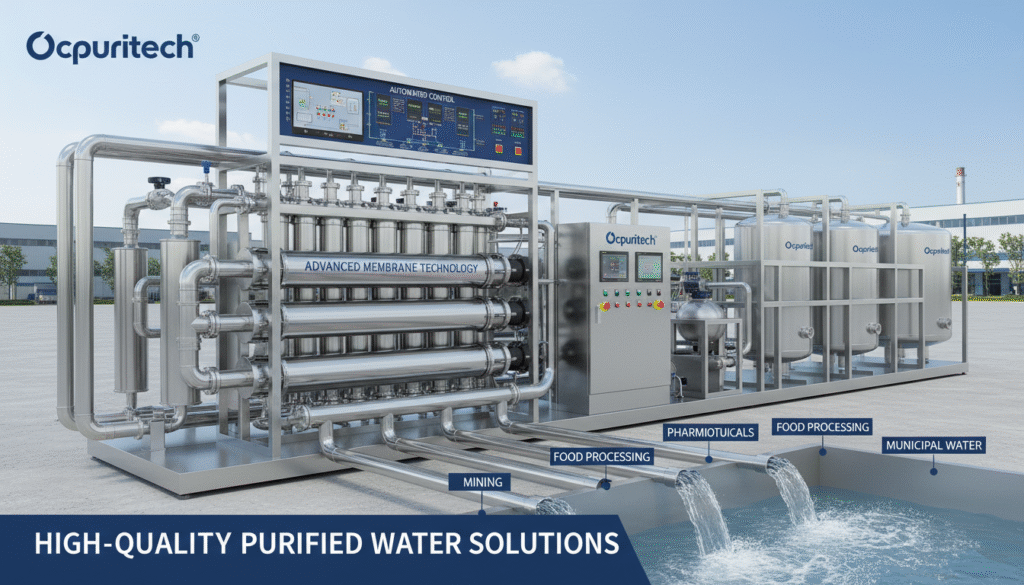

Ocpuritech’s industrial water purification product line includes state-of-the-art solutions:

- Remote Control Reverse Osmosis System

- Brackish Water RO System

- Seawater Desalination System

- Ultrafiltration (UF) System

- Nanofiltration Systems

- EDI Ultrapure Water System

Crucial for maintaining system longevity and quality, our pre-treatment systems include Sand Filters, Carbon Filters, and Softeners, which are vital for preparing raw water for advanced treatment.

B. Functions and Advantages

Each Ocpuritech system offers unique functionalities. Reverse Osmosis excels in high-efficiency desalination, removing Total Dissolved Solids (TDS), ions, bacteria, and viruses. Ultrafiltration effectively removes suspended solids, colloids, and microbes. Our EDI systems continuously and stably produce ultrapure water, essential for sensitive applications. Together, these technologies ensure highly efficient impurity removal, water softening, and contaminant separation and recovery, significantly improving water quality and operational efficiency.

C. Key Applicable Industries

Ocpuritech’s solutions cater to a wide array of industries:

- High-Purity Water Needs: Mining, pharmaceuticals, cosmetics, laboratories, ultrapure water for urea production, hydrogen generation, medical applications, photovoltaics, and boiler feed water.

- Drinking Water Treatment: Municipal water supply, river water, groundwater, well water, food processing (beverage plants, seasoning factories, ice factories, breweries), schools, government facilities, hospitals.

- Special Applications: Agriculture (plantations, animal husbandry), recycled water systems, dyeing factories, seawater desalination, and bottled water production lines.

We pride ourselves on meeting the specific water quality requirements of these diverse sectors, affirming our commitment to versatile and effective water treatment.

II. Technical Principles and Key Components: The Core Driving Water Treatment Efficiency

Understanding the technical backbone of Ocpuritech’s water treatment plant machinery is crucial to appreciating its efficiency. Our systems leverage advanced technologies and meticulously selected components to ensure optimal performance.

A. Membrane Separation Technology

Membrane separation is a cornerstone of modern water treatment, offering high efficiency, wide applicability, and minimal environmental impact in industrial processes. Processes like reverse osmosis use pressure to remove dissolved impurities, purifying water effectively for reuse (J.MARK Systems, 2023).

- Reverse Osmosis (RO): The process relies on a semi-permeable membrane that effectively rejects TDS, ions, bacteria, and viruses. Ocpuritech’s Remote Control Reverse Osmosis System exemplifies how automation streamlines pollutant removal. Key components include RO membrane elements, high-pressure pumps, and pressure vessels.

- Ultrafiltration (UF): This technology uses physical sieving to remove suspended solids, colloids, microorganisms, and large organic molecules. Ocpuritech utilizes UF as a robust pre-treatment for RO or as a standalone system for food processing and drinking water, featuring UF membrane modules and recirculation pumps.

- Nanofiltration (NF): Positioned between RO and UF, NF removes divalent ions and some smaller organic molecules, ideal for specific applications like water softening.

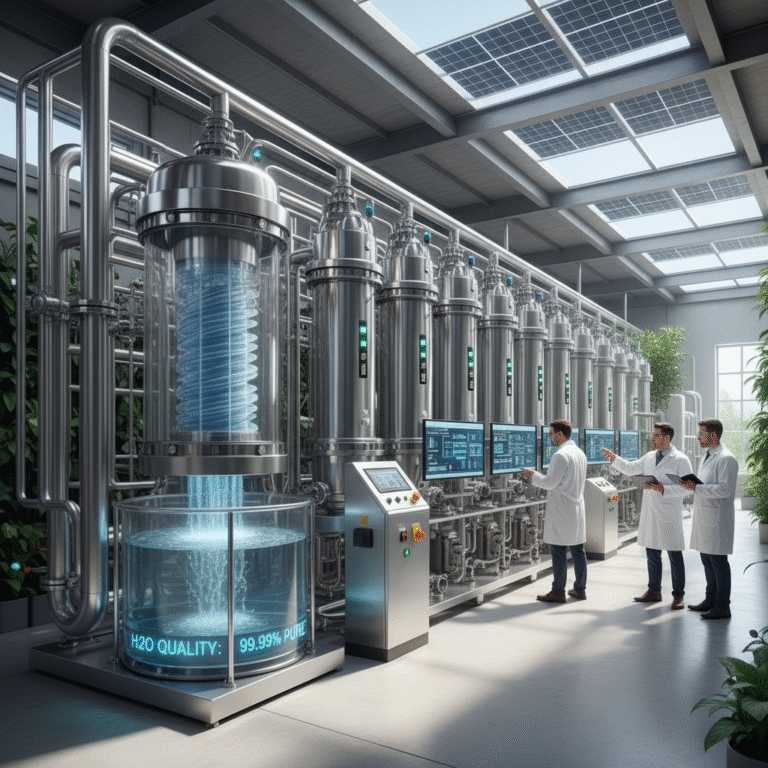

- EDI (Electrodeionization): Combining electrodialysis with ion exchange, EDI continuously produces ultrapure water. It’s particularly beneficial in pharmaceutical and laboratory settings where water purity is paramount.

B. Automation Control Systems and Smart Integration

Automation is integral to Ocpuritech’s modern water treatment equipment. Our Remote Control RO Systems integrate advanced control systems, sensors, and software to monitor and optimize treatment processes, improving efficiency, water quality, and cost savings (PowertechMax, 2023). Automated systems leverage technologies like SCADA and IoT to enhance responsiveness and accuracy in flow regulation, chemical dosing, membrane cleaning, and quality monitoring, reducing manual labor and improving operational efficiency (Alantech, 2022). These systems facilitate real-time monitoring of water quality parameters, automated backwashing, fault diagnostics, data display, and remote control, ultimately reducing labor costs, enhancing operational stability, optimizing energy consumption, and extending equipment lifespan.

C. Pre-treatment and Post-treatment Technologies

- Pre-treatment: Stages like sand filtration, carbon filtration, and softening are critical for removing suspended solids, residual chlorine, hardness, and organic matter. This protects subsequent membrane processes. Ocpuritech customizes pre-treatment solutions based on raw water quality.

- Post-treatment: Technologies such as UV sterilization and precision filtration ensure that the treated water meets specific quality standards required for its end use.

D. Ocpuritech’s Quality Control on Key Components

Quality is paramount. We select high-grade membrane elements, pumps, valves, and instrumentation from reputable suppliers. This commitment to quality ensures the overall performance and reliability of our systems, a factor critical for industrial applications where downtime is costly.

III. Price Analysis: ROI of Ocpuritech Equipment

Investing in advanced water treatment plant machinery involves various cost considerations, yet offers significant long-term returns. Understanding the overall investment and operational expenses is key to evaluating the value provided by Ocpuritech’s solutions.

A. Basic System Cost Components

The initial investment covers:

- Main Equipment: This includes the core RO unit, UF system, EDI system, etc.

- Control System: The Programmable Logic Controller (PLC), instrumentation, and sensors that enable automated operations.

- Installation and Commissioning: Professional onsite services by our technical personnel to ensure seamless setup and optimal functioning.

B. Additional Modules and Customization Costs

To cater to specific project needs, additional costs may arise from:

- Pre-treatment Modules: Depending on raw water quality, adding multi-stage filtration, softening, or chemical dosing systems.

- Post-treatment Modules: Integrating UV sterilization or precision filters to achieve specific effluent standards.

- Customized Design: Requirements for special flow rates, materials, or explosion-proof/corrosion-resistant features.

C. Operating and Maintenance Costs

Ongoing expenses are critical for a complete financial picture:

- Energy Consumption: Electricity for pumps and control systems.

- Consumables Replacement: Filter cartridges, RO membrane elements, filter media, etc. Ocpuritech also supplies spare parts such as filter cartridges, UV lamps, FRP tanks, and carbon.

- Labor Costs: For routine inspections and maintenance.

- Repair Costs: Potential component repairs or replacements.

Key factors influencing ROI in industrial water treatment systems include water quality requirements, technology choices, operational and energy efficiency, and maintenance costs. Initial investments range widely, with operational costs estimated at 15-25% of capital cost annually, and typical payback periods of 2-5 years (Porvoo, 2024).

D. Highlighting Cost-Effectiveness and Long-Term ROI

Ocpuritech equipment, through its efficient operation, low failure rate, and extended lifespan, significantly reduces the Total Cost of Ownership (TCO). The indirect contributions of high-quality water to production efficiency, enhanced product quality, and compliance with environmental regulations add intangible yet substantial value. High-quality water reduces unexpected shutdowns and ensures consistent product quality, thereby improving overall profitability.

IV. Performance Specifications and Quality Assurance: Ocpuritech’s Excellence Standards

Ocpuritech’s commitment to excellence is reflected in our rigorous performance specifications and unwavering quality assurance processes for all our water treatment plant machinery.

A. Key Performance Indicators

Our equipment is designed to meet stringent performance metrics:

- Product Water Flow Rate: Tailored to different models and application scenarios.

- Desalination/Rejection Rate: RO membranes typically achieve ≥ 98%, while UF membranes boast high bacterial removal rates.

- Recovery Rate: RO systems generally range from 50-75%, with potential for higher recovery through optimized technology.

- Effluent Water Quality: Measured by TDS, conductivity, turbidity, and microbiological indicators, ensuring compliance with specific industry standards (e.g., drinking water standards, pharmacopoeia standards).

- Automation Level: Featuring PLC control and remote monitoring capabilities for enhanced operational intelligence.

- Energy Efficiency: Optimized to minimize kW/m³ of water treated.

B. Material Selection and Manufacturing Process

We meticulously select materials and processes to ensure durability and purity:

- Water Contact Parts: Constructed from food-grade stainless steel (SS304/316L) or corrosion-resistant UPVC.

- Membrane Elements: Sourced from internationally renowned brands or Ocpuritech’s own high-performance membranes.

- Pumps and Valves: Acquired from high-quality, reliable suppliers.

Ocpuritech operates two standardized factories in Guangzhou and Jiangmen, totaling over 10,000 square meters. These facilities guarantee high-quality production and cost-effectiveness, ensuring our manufacturing standards meet global expectations.

C. Quality Control and Certification Standards

Our stringent quality controls cover every stage:

- Internal Quality Inspection: Multi-stage, rigorous testing from raw material procurement to final product delivery.

- Industry Certifications: Adherence to standards such as CE and RoHS, with ISO 9001 being pertinent when applicable.

- Testing: Comprehensive performance and durability tests conducted before shipment.

This meticulous approach ensures Ocpuritech provides global clients with high-quality, internationally compliant water treatment plant machinery.

V. Market and Application Scenarios Analysis: Ocpuritech’s Global Perspective

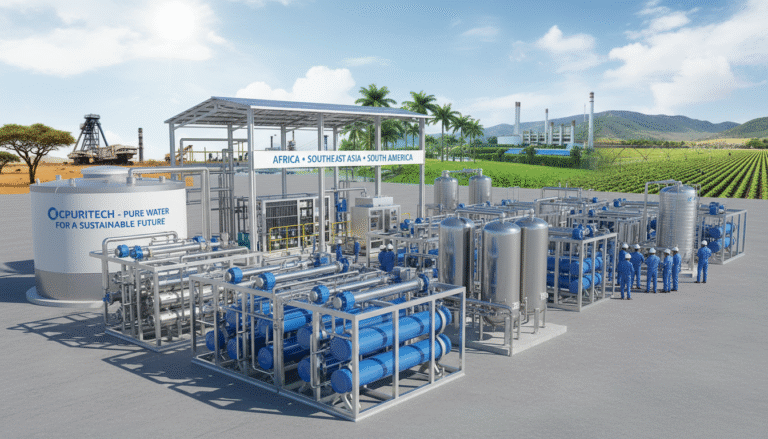

Ocpuritech approaches the global market with a clear understanding of regional water challenges and industrial demands, providing tailored water treatment plant machinery solutions.

A. Water Quality Characteristics and Industry Demands in Target Regions

In regions like Southeast Asia, Africa, and South America, specific challenges define the water treatment landscape:

- Water Resource Diversity: Dealing with surface water, groundwater, brackish water, and seawater.

- Specific Contaminant Challenges: Addressing high hardness, elevated TDS levels, microbiological contamination, and heavy metals.

- Industrial Development Needs: Supporting sectors such as mining, agriculture, food processing, and pharmaceuticals.

Ocpuritech is adept at designing custom solutions for these diverse water qualities and industry requirements.

B. Adaptability of Industry-Specific Solutions

Ocpuritech’s equipment is engineered for versatility across various applications:

- Pure Water Projects: We meet the stringent requirements for ultrapure water used in urea production, hydrogen generation, medical facilities, pharmaceuticals, photovoltaic manufacturing, cosmetics, and laboratories.

- Drinking Water Projects: Providing safe and reliable drinking water solutions for bottled water production lines, schools, government institutions, and hospitals.

- Agricultural Use: Addressing the specific water treatment needs of plantations and animal husbandry.

- Seawater Desalination: Supplying fresh water for industrial or domestic use in coastal areas.

The global market for water and wastewater treatment technologies is experiencing remarkable expansion, driven by stricter environmental regulations and technological advancements (BCC Research, 2024). Public utilities and industries like pharmaceuticals, food and beverage, oil and gas, and mining are investing in modern treatment plants and specialized solutions (BCC Research, 2024).

C. Ocpuritech’s Global Market Presence and Services

Ocpuritech products have earned the trust and acclaim of clients worldwide. We are committed to fostering business growth through sincere service and professional technical expertise. Our target customer base includes:

- Water treatment equipment wholesalers, agents, and spare parts distributors (e.g., PP filter cartridges, blue bottles, wound filter cartridges).

- End-users across pure water projects, drinking water projects, and seawater desalination facilities.

- Global cross-border e-commerce buyers.

VI. Case Studies: Real-World Applications and Customer Benefits of Ocpuritech Equipment

Witnessing the practical application of Ocpuritech’s water treatment plant machinery underscores its value. These real-world examples highlight how our solutions drive efficiency and deliver tangible benefits across various industries.

A. Case 1: Industrial Pure Water Production

Scenario: A pharmaceutical plant required highly stable, GMP-compliant ultrapure water for its critical processes. Traditional methods struggled to maintain consistent purity and were prone to costly downtime.

Ocpuritech Solution: We implemented an EDI Ultrapure Water System coupled with a multi-stage pre-treatment system, including UF and RO, to handle diverse raw water conditions. The system incorporated real-time monitoring and automated controls to maintain strict water quality parameters.

Effect: The treated water consistently met pharmacopoeia standards, with conductivity reliably below 0.1 µS/cm. The system operated with remarkable stability, significantly reducing reagent consumption for regeneration and minimizing manual intervention. This enhanced water quality directly contributed to higher product integrity and fewer batch rejections, leading to over 20% savings in chemical costs and improved operational uptime.

B. Case 2: Bottled Drinking Water Production Line

Scenario: A beverage factory aimed to expand its bottled water production with a high-quality, compliant product. The existing water source had inconsistent quality, posing a challenge to product safety and taste.

Ocpuritech Solution: We provided a complete solution comprising a high-efficiency RO system, post-treatment UV sterilization, and integrated it with a full bottled water filling production line. Our system included automated backwashing and CIP (Clean-in-Place) functionality to ensure continuous operation and hygiene.

Effect: The system consistently delivered water with contaminant reduction and improved sustainability, ensuring product safety and superior taste that exceeded national drinking water standards. Production efficiency increased by 30% due to reduced downtime and consistent water supply, directly supporting the client’s business growth and market expansion. The return on investment was achieved within 3 years, largely due to increased output and reduced operational risks.

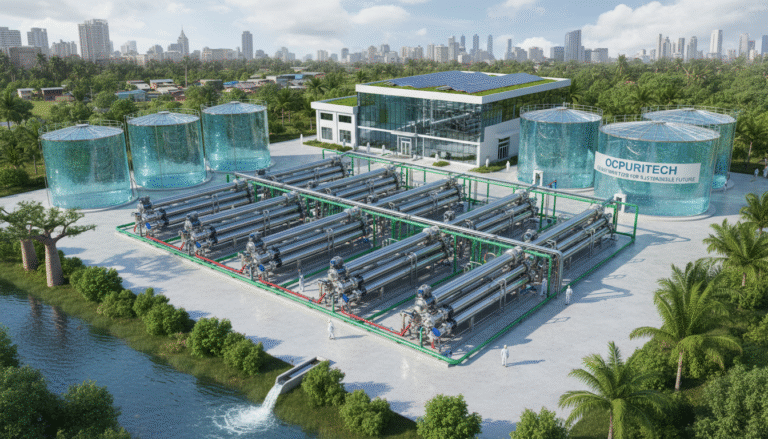

C. Case 3: Brackish Water/Seawater Desalination Project

Scenario: A coastal industrial zone faced severe freshwater scarcity, relying heavily on expensive imported water. The local brackish water source had high salinity and turbidity, making it unsuitable for industrial use without extensive treatment.

Ocpuritech Solution: We deployed a customized Brackish Water RO System, specifically engineered to handle the high TDS and varying turbidity of the raw water. For potential future expansion, the system was designed with modules that could be easily upgraded to a Seawater Desalination System. Comprehensive pre-treatment including coagulation, sedimentation, and multi-media filtration was integrated to protect the RO membranes from fouling. Water treatment methods like sedimentation, filtration, and reverse osmosis are crucial in treating mining wastewater with high salinity and contaminants, ensuring effective removal of solids and dissolved impurities (Veolia WTS, 2024).

Effect: The Ocpuritech system provided a stable and cost-effective source of industrial process water, reducing the dependency on external water supplies. The client reported a 45% reduction in water procurement costs annually. The system’s robust design and automated operation led to minimal maintenance requirements, further reducing operational expenses. This provided a significant competitive advantage for the industrial park and supported sustainable development in the region.

D. Quantifiable Results and Customer Testimonials

These cases demonstrate that Ocpuritech’s equipment delivers measurable benefits, such as significant improvements in water quality, substantial cost savings, and enhanced recovery rates. Our clients consistently praise Ocpuritech for our technical expertise and reliable solutions, trusting us to help them achieve their operational and business goals.

VII. Customized Solutions and Service Support: Ocpuritech’s Customer Commitment

Ocpuritech prides itself on a deep commitment to customer success, offering tailored solutions and unwavering support for every piece of water treatment plant machinery we provide.

A. Customization of Pre-treatment and Post-treatment Options

Based on a detailed analysis of raw water quality reports, we design optimal pre-treatment solutions specifically for your needs. This ensures the protection of the primary treatment stages and enhances overall system efficiency. Additionally, we provide diverse post-treatment options to match the required effluent quality for various end uses. Ocpuritech is your single source for complete water purification equipment and all necessary spare parts.

B. Engineering Design and Installation Services

Our team of expert engineers offers comprehensive project consultation, solution design, and equipment selection advice. We also provide on-site installation guidance and commissioning services to ensure your equipment operates smoothly and efficiently from day one.

C. Operation & Maintenance and After-Sales Support

Ocpuritech provides extensive technical training to empower your team with the knowledge for equipment operation and routine maintenance. Our efficient spare parts supply chain ensures quick response and availability of components such as filter cartridges, UV lamps, FRP tanks, carbon, flow meters, and filling machines. We also offer prompt troubleshooting and remote technical support, demonstrating that Ocpuritech’s genuine service and professional technical experience are key to earning customer trust.

VIII. Manufacturer Introduction and Partnership Advantages: Reasons to Choose Ocpuritech

Choosing Ocpuritech means partnering with a leader in the water purification industry, committed to quality, innovation, and customer satisfaction.

A. Ocpuritech Company Profile and Development History

Guangzhou Aomi Water Purification System Manufacture Co., Ltd. (Ocpuritech), established in 2011, has dedicated 14 years to the water purification industry. We pride ourselves on being a professional system manufacturer, not merely a supplier of spare parts. Our two standardized factories, covering over 10,000 square meters, attest to our significant production capabilities and scale, ensuring both high quality and cost-effectiveness.

B. Technical Strength and R&D Investment

Our core strength lies in our experienced engineering team and continuous investment in research and development. This commitment to innovation keeps our products at the forefront of the industry, exemplified by the integration of smart technologies like remote control systems into our water treatment plant machinery.

C. Certifications and Industry Recognition

Ocpuritech holds relevant domestic and international certifications, including CE and RoHS, which demonstrate our adherence to global standards. Our reputation in the global market is built on consistent quality and positive customer feedback.

D. Partnership Advantages and Value Proposition

We offer competitive products and robust support to water treatment equipment wholesalers and agents. For end-users, we deliver high-quality and cost-effective solutions. Ocpuritech’s brand value emphasizes “protecting the environment,” reflecting our dedication to sustainable practices and responsible water management.

IX. Conclusion and Investment Advice: Ocpuritech Powering an Efficient Future

The strategic investment in Ocpuritech’s water treatment plant machinery represents a commitment to operational excellence and environmental stewardship. Our advanced systems are designed not just to meet, but to exceed industry standards, ensuring superior water quality and enhanced process efficiency.

A. Summarizing Equipment Advantages

Ocpuritech’s water treatment plant machinery offers a comprehensive array of advantages: significant improvements in efficiency, guaranteed water quality, reduced operational costs, and a minimized environmental footprint. Our solutions boast broad applicability across diverse industries and water types, coupled with extensive customization capabilities tailored to specific client needs.

To maximize your return on investment, we advise enterprises to carefully select Ocpuritech equipment that perfectly matches their specific raw water characteristics and operational demands. Emphasizing regular maintenance and the timely replacement of consumables is crucial for sustained optimal performance. Additionally, considering the level of automation and intelligence embedded in your chosen equipment will unlock long-term operational benefits, including reduced labor and energy costs.

C. Call to Action

We invite you to connect with the Ocpuritech expert team for a complimentary consultation and customized solution design. Explore our official website to delve deeper into our product offerings and successful case studies. “Choose Ocpuritech, invest in sustainable productivity, and together, let’s achieve efficient water resource utilization and environmental protection.”

Frequently Asked Questions

Q1: What types of water treatment plant machinery does Ocpuritech offer for industrial use?

Ocpuritech offers a comprehensive range, including Remote Control RO, Brackish Water RO, Seawater Desalination, UF, NF, and EDI ultrapure water systems, alongside pre-treatment solutions like sand and carbon filters.

Q2: How does Ocpuritech’s water treatment plant machinery improve process efficiency?

Our machinery enhances efficiency through advanced membrane technologies, automated controls, and optimized designs, ensuring consistent high-quality water, reduced downtime, and lower operational costs in industrial processes.

Q3: Can Ocpuritech’s water treatment equipment be customized for my specific industry needs?

Absolutely. Ocpuritech specializes in providing customized solutions, designing pre-treatment, main systems, and post-treatment options tailored to your raw water quality and specific industry requirements.

Q4: What are the key industries that benefit from Ocpuritech’s water treatment plant machinery?

Our machinery serves diverse sectors, including mining, pharmaceuticals, food processing, cosmetics, laboratories, aquaculture, agriculture, and general manufacturing, providing solutions for various water qualities.

Q5: How does Ocpuritech ensure the quality and reliability of its water treatment plant machinery?

We ensure quality through stringent material selection, advanced manufacturing in our standardized factories, multi-stage internal quality control, and adherence to international certifications like ISO and CE.

Q6: What is the typical lifespan of Ocpuritech’s water treatment plant machinery components?

The lifespan varies by component. With proper operation and maintenance, including timely replacement of consumables like filter cartridges and RO membranes, our machinery is designed for long-term, reliable performance.

Q7: Does Ocpuritech provide installation and after-sales support for its water treatment plant machinery?

Yes, Ocpuritech offers comprehensive services, including project design, installation guidance, commissioning, technical training, spare parts supply, and remote support, ensuring seamless operation.

Q8: How can I assess the return on investment (ROI) for Ocpuritech’s water treatment plant machinery?

ROI can be assessed by considering reduced operational costs (energy, chemicals), extended equipment lifespan, improved product quality, compliance with regulations, and increased overall production efficiency.

Q9: What role does automation play in Ocpuritech’s water treatment plant machinery?

Automation, particularly in our Remote Control RO Systems, allows for real-time monitoring, automatic operation, fault diagnosis, and remote control, leading to stable performance, reduced labor, and optimized energy use.

Q10: Where can I find more information or request a quote for Ocpuritech’s water treatment plant machinery?

You can visit our official website for product details and case studies, or contact our expert team directly for a free consultation and to request a tailored quotation.