In today’s rapidly evolving landscape of water treatment, reverse osmosis water systems have emerged as fundamental assets within industrial and commercial sectors. Their ability to deliver consistent, high purity water positions them as indispensable in applications ranging from pharmaceutical manufacturing to municipal supply. This article delves into the core components and multi-scale capacities of these systems, illustrating their technological evolution and broad industrial relevance.

Core Components and Technology of Reverse Osmosis Water Systems

1. Reverse Osmosis Membrane Modules

At the heart of any reverse osmosis water system lies the membrane technology responsible for selective permeability. Modern RO membranes, typically thin-film composite types, offer remarkable effectiveness in removing up to 99% of dissolved solids, microorganisms, and contaminants. Their operational pressures generally range from 150 to 600 psi, adjusted depending on feed water quality.

System capacities span a wide spectrum, usually categorized into:

- Small-scale units: 500 to 2,500 gallons per day (GPD), often used in laboratories and small commercial kitchens.

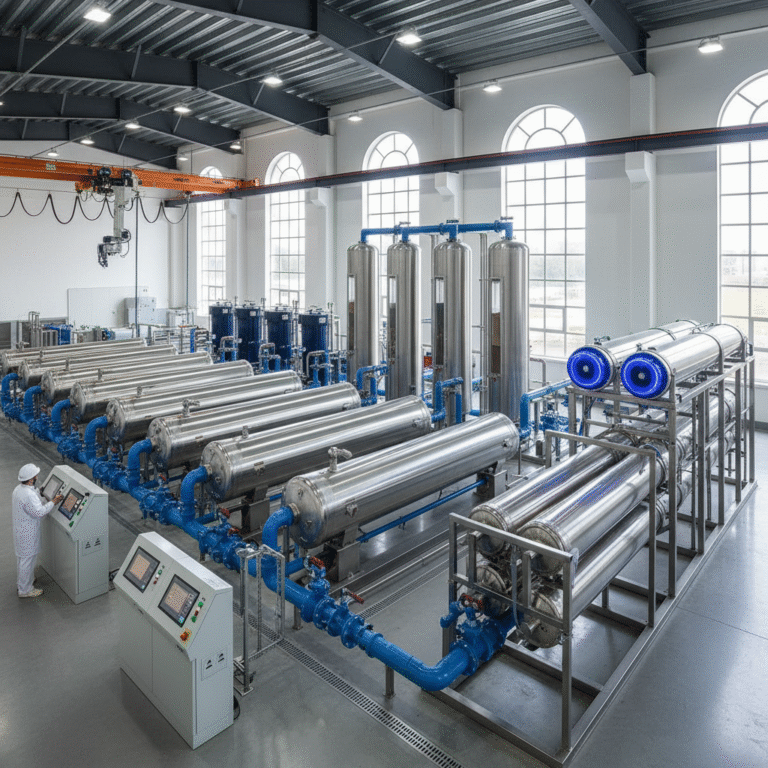

- Medium-scale systems: 10,000 to 100,000 GPD, targeting mid-sized manufacturing plants and food processing facilities.

- Large industrial arrays: 500,000 GPD and above, deployed in large-scale water purification plants and power generation facilities.

The performance advantages include high rejection rates of inorganic and organic substances, energy-efficient membranes reducing operational costs, and long service life facilitated by advanced polymer structures.

2. Filtration and Softening Systems

Pre-treatment is critical to extend membrane life and maintain system efficiency. Typically, a multi-stage filtration setup precedes the RO membranes:

- Sand and carbon filters remove suspended solids and organic matter.

- Ion exchange softeners reduce hardness by removing calcium and magnesium ions.

- Micron filters to trap fine particles down to 5 microns or lower.

Such staged filtration setups are modularly scaled based on system size, ensuring optimal feedwater quality for the RO process. This approach dramatically decreases fouling incidents and maintenance downtime.

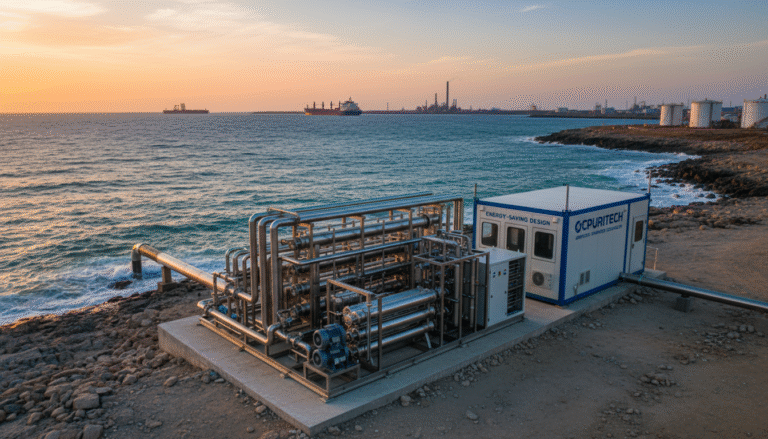

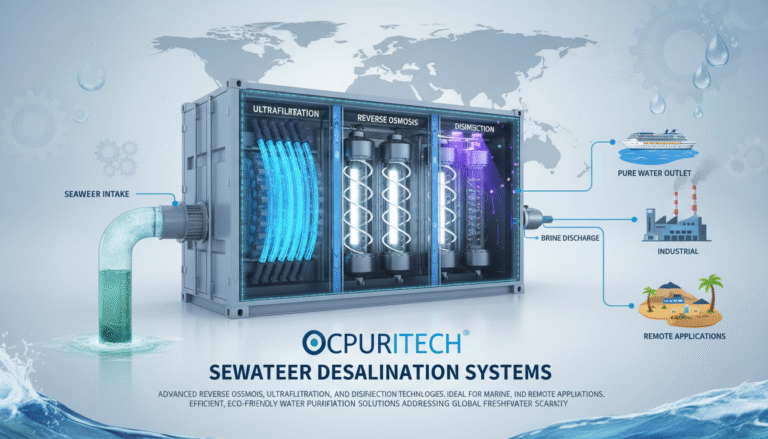

3. Containerized and Modular RO Systems

Recent innovations have introduced fully containerized RO units, integrating all components – pre-treatment, membranes, pumps, and control units – into standard shipping containers. These plug-and-play systems boast:

- Capacity options from 1,000 GPD for remote or portable applications to over 100,000 GPD for industrial-scale projects.

- Robust construction suitable for harsh environments including marine and desert installations.

- Advanced automation and remote monitoring for operational precision and quick diagnostics.

The modularity enables rapid deployment in disaster relief or off-grid setups, dramatically enhancing response capabilities and water security.

4. Cleaning and Sterilization Technologies

Maintaining membrane integrity and product water quality requires efficient cleaning and microbial control strategies. Ultraviolet (UV) disinfection is a common post-treatment step that effectively eradicates bacteria and viruses without harmful chemicals. Additionally, periodic chemical cleaning protocols using citric acid or alkaline agents keep membranes free from scaling and biofilm formation.

Combining RO with UV sterilization ensures total compliance with strict water purity standards, especially in pharmaceutical and food processing industries where contamination risk is minimal.

Manufacturers’ Expertise and Quality Assurance

Leading manufacturers in the reverse osmosis space combine decades of applied research with rigorous quality control to guarantee system reliability. Their innovation pipelines include:

- Development of high-flux membranes that increase throughput while lowering energy consumption

- Integration of intelligent control systems capable of self-diagnosis and predictive maintenance alerts

- Customizable design to address unique water chemistries and operational contexts

Field-tested solutions undergo extensive performance validation and are often certified in accordance with NSF/ANSI 58 standards, underscoring their safety and effectiveness in drinking water applications.

Diverse Applications Across Industries

Reverse osmosis water systems demonstrate versatility across numerous sectors, as highlighted by the following real-world use scenarios:

- Seawater Desalination: Coastal industrial plants employ large-scale RO arrays to convert seawater into potable and process water, helping regions with scarce freshwater resources meet demand sustainably.

- Portable and Emergency Water Supply: In recent projects supporting humanitarian aid, containerized RO units capable of producing 10,000 GPD were deployed to remote villages, delivering safe drinking water swiftly post-disaster.

- Space Exploration Drinking Water: Pioneering research has adapted RO technology for long-duration space missions, developing highly compact and energy-efficient systems that recycle and purify water onboard spacecraft, ensuring astronaut hydration and health beyond Earth.

Practical Insights from Industry Engagement

In my experience overseeing the upgrade of an RO system at a beverage manufacturing facility handling 50,000 gallons daily, the transition to modular membranes paired with advanced pre-treatment reduced operational energy by 22% and membrane downtime by more than 40%. These improvements translated directly into cost reductions and product consistency enhancements.

Additionally, collaboration with a municipal water authority revealed that adopting containerized RO units for remote community water supply cut installation time by 60% compared to conventional systems, while the integrated remote monitoring drastically lowered manual inspection costs.

Conclusion

Industrial and commercial water treatment continues to evolve through the innovation embedded within advanced reverse osmosis water systems. From sophisticated membrane technology and comprehensive filtration to modular design and automated sterilization, these systems are tailored to meet demanding purity requirements across diverse applications. Leveraging manufacturer expertise alongside proven operational insights ensures reliable, cost-effective solutions aligned with sustainable water management goals.

References

- Future Market Insights, “Reverse Osmosis Pump Market Trends & Forecast 2025-2035”

- Grand View Research, “Reverse Osmosis in Point of Entry Water Treatment Systems Market Outlook”

- NSF International, “NSF/ANSI 58: Reverse Osmosis for Drinking Water Standards”

- MarketsandMarkets, “Reverse Osmosis Membrane Market Size and Industry Share Forecast”