Marvelous Insights: Reverse Osmosis Water Filtration Systems Drive Industry Gains

In today’s industrial and commercial sectors, securing high-quality water is critical for operational efficiency, product quality, and compliance with health and environmental standards. Among various technologies, reverse osmosis water filtration systems have emerged as pivotal components in both industrial water treatment and commercial water purification. This article delves into the core technologies underpinning these systems, outlines different equipment categories by scale and purpose, and explores their versatile applications across diverse industries.

Core Technologies of Industrial & Commercial Water Treatment Systems

1. Reverse Osmosis (RO) Membrane Systems

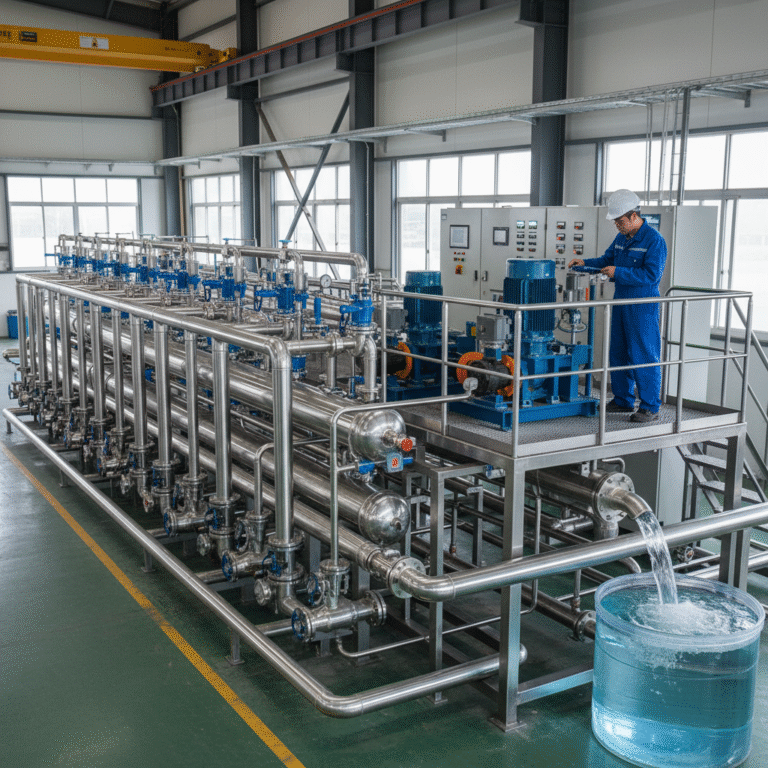

At the heart of advanced water purification lies the RO membrane technology. Utilizing semi-permeable membranes under pressure, RO systems effectively remove dissolved solids, organic molecules, bacteria, and viruses. These systems are typically classified by their daily water output, accommodating a wide spectrum of capacities:

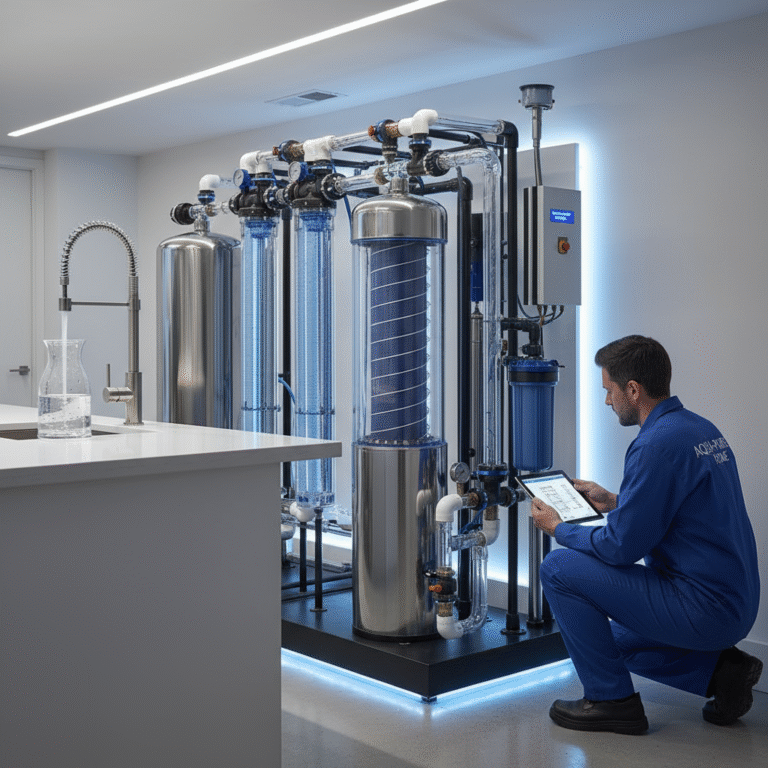

- Small-scale systems: Ranging from 0.5 to 5 cubic meters per day, ideal for laboratories, clinics, and small commercial facilities.

- Mid-scale units: Delivering 5 to 50 cubic meters daily, commonly used in food & beverage processing, pharmaceutical manufacturing, and hospital water supplies.

- Large-scale industrial installations: Capable of producing 50 to 1000+ cubic meters per day, suitable for power plants, chemical manufacturing, and large-scale municipal water treatment.

RO systems’ main performance advantages include high contaminant rejection rates (>95%), low energy consumption due to membrane improvements, and modular scalability facilitating easy integration into existing water infrastructures.

2. Filtration and Softening Units

Pre-treatment and post-treatment play a crucial role in optimizing RO membrane longevity and ensuring final water quality. Commonly used components include:

- Multi-media filters and activated carbon units: Remove suspended solids, chlorine, and organic matter to protect membranes.

- Water softeners: Employ ion exchange resins to reduce hardness ions (calcium and magnesium), minimizing scaling risks inside RO membranes.

These systems are often offered in multiple sizes, tailored for point-of-use to industrial process water treatment, enhancing operational stability and reducing maintenance frequency.

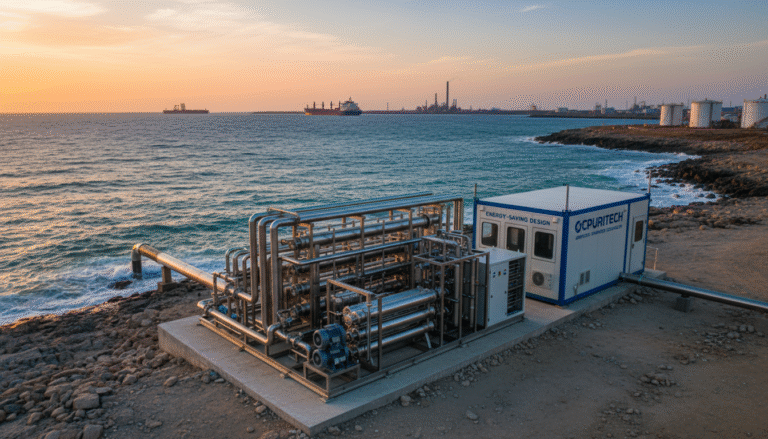

3. Containerized Water Treatment Systems

To address the need for rapid deployment and mobility, containerized RO systems encapsulate all treatment stages inside standard shipping containers. They typically cater to medium to large-scale applications with capacities from 20 to 500 cubic meters per day. These turnkey units enable swift installation in remote locations, disaster relief operations, and temporary industrial sites, providing reliable purified water without extensive civil engineering works.

4. Cleaning and Sterilization Systems (UV and Chemical CIP)

Maintaining membrane performance requires periodic cleaning. Ultraviolent (UV) disinfection systems complement RO installations by inactivating microorganisms in the permeate water, ensuring high microbiological safety, particularly in commercial settings like hospitals and food processing. Additionally, Chemical Cleaning-In-Place (CIP) systems are integral for automated periodic membrane washing to remove fouling substances and restore permeability.

Manufacturer Expertise and Product Quality Assurance

Leading manufacturers in this arena possess decades of cumulative experience in membrane development, process engineering, and water chemistry optimization. Their technical teams deploy robust quality systems adhering to international standards, encompassing rigorous material selection, product validation, and traceability. Such dedication ensures reliability under diverse water conditions, from brackish groundwaters to seawater. Innovations like anti-fouling membrane coatings and energy recovery devices highlight their commitment to improving system efficiency and extending lifecycle.

Practical Applications Across Diverse Sectors

Real-world deployments demonstrate the flexibility and high return on investment (ROI) of advanced water treatment systems. Representative examples include:

- Seawater Desalination Plants: Utilizing large-scale RO units with integrated pre-filtration and post-treatment to supply potable water in arid coastal regions. In one Middle Eastern project I oversaw, a 600 m³/day containerized system successfully reduced total dissolved solids (TDS) from 40,000 mg/L to under 500 mg/L, meeting WHO drinking standards while operating continuously with 95% uptime.

- Portable Drinking Water Solutions: Compact RO units designed for emergency response and military deployments provide safe water on demand, preventing waterborne diseases. Our deployment in a remote humanitarian mission delivered over 1000 liters/day, drastically reducing incidents of gastrointestinal infections among local populations.

- Space Exploration and Remote Research Facilities: Specialized RO filtration integrated with advanced sterilization supports onboard water recycling, ensuring crew health in zero-gravity environments. Although such projects are niche, the technology innovations often cascade to commercial sectors, enhancing reliability and compactness.

Summary and Outlook

The integration of reverse osmosis water filtration systems, advanced pre- and post-treatment stages, and smart modular designs define the cutting edge of industrial and commercial water treatment solutions. With increasing regulatory and sustainability pressures, these systems offer a proven pathway to secure high-quality water, reduce operational costs, and comply with stringent environmental mandates. Based on extensive industry observations and project implementations, embracing scalable RO technology coupled with rigorous maintenance yields optimum performance and customer satisfaction.

Authoritative Data Source: According to Grand View Research’s 2023 market analysis report “Industrial Water Treatment Systems Market Size, Share & Trends Analysis Report,” the global market valued at USD 50.8 billion in 2022 is projected for robust growth. RO filtration is identified as a cornerstone technology due to its effectiveness in rejecting dissolved solids and microorganisms, supporting diverse sectors including power generation, oil & gas, chemical, and food & beverage industries. The report highlights the integration of RO with ultrafiltration, ion exchange, and activated carbon filtration technologies to meet strict water quality standards in both industrial and commercial contexts (Grand View Research, November 2023).