Mastering Water Quality: Ultrafiltration Water Treatment Systems in Commercial Use

Water quality management remains a critical challenge in industries and commercial facilities worldwide. Among the cutting-edge solutions available, ultrafiltration water treatment systems have emerged as indispensable for ensuring safe, reliable, and efficient purification. This article provides a comprehensive overview of ultrafiltration technology, highlighting core equipment components, their performance parameters, and application scopes across different scales. Our goal is to guide professionals in selecting and integrating these advanced systems to meet diverse operational requirements.

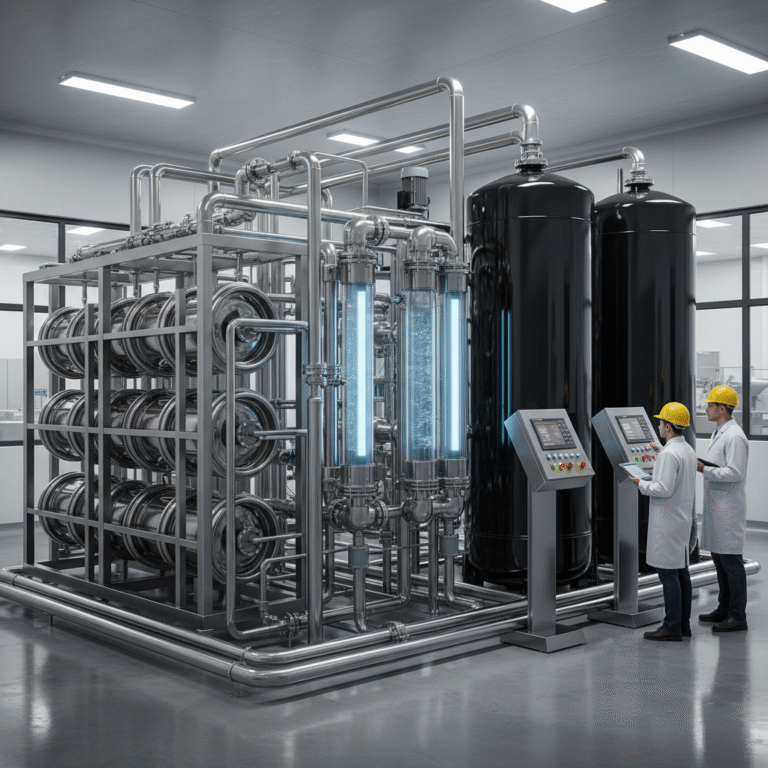

1. Core Ultrafiltration Equipment Modules

1.1 Ultrafiltration Membrane Modules

The heart of any ultrafiltration system is its membrane module, designed to operate under pressure-driven separation. These membranes effectively remove suspended solids, bacteria, viruses, endotoxins, and large molecular weight contaminants without chemical additives. Typically, modules utilize polymeric membranes, which currently dominate approximately 65% of the market share due to their flexibility and cost-effectiveness. Ceramic membranes, though less common, offer superior chemical and thermal stability and are gaining traction for treating highly contaminated effluents.

Performance range: Standard ultrafiltration membrane systems come in various configurations catering to capacities from small-scale commercial units (~1 cubic meter/hour) up to large industrial systems exceeding 500 cubic meters/hour. Modular designs allow system scalability for specific flow and quality demands.

Typical applications: Food and beverage production lines, pharmaceutical water preparation, and pretreatment for reverse osmosis (RO) plants in industrial and municipal facilities.

1.2 Pre-Filtration and Softening Systems

Pre-treatment stages commonly integrate sediment filters and water softeners to reduce turbidity and hardness, protecting the ultrafiltration membranes and prolonging system longevity. Softening units often use ion-exchange resins to minimize scaling risks, which is essential in maintaining consistent permeate flow and membrane integrity.

Capacity categories: Systems range from compact units serving a few hundred liters per hour to extensive setups capable of conditioning thousands of cubic meters daily.

Advantages: Enhanced membrane lifespan, reduced chemical Cleaning-In-Place (CIP) frequency, and stabilized operational efficiency.

1.3 Containerized Ultrafiltration Solutions

Containerized systems offer a prefabricated, plug-and-play solution ideal for remote locations or rapidly deployable commercial needs. These systems integrate all process stages inside standardized shipping containers for ease of transport, installation, and maintenance.

Production scale: Typical capacities include 10, 50, and 100 cubic meters per day modules, designed for applications ranging from small community water supply to emergency and military operations.

Use cases: Remote beverage bottling plants, mobile medical facilities, and temporary commercial constructions.

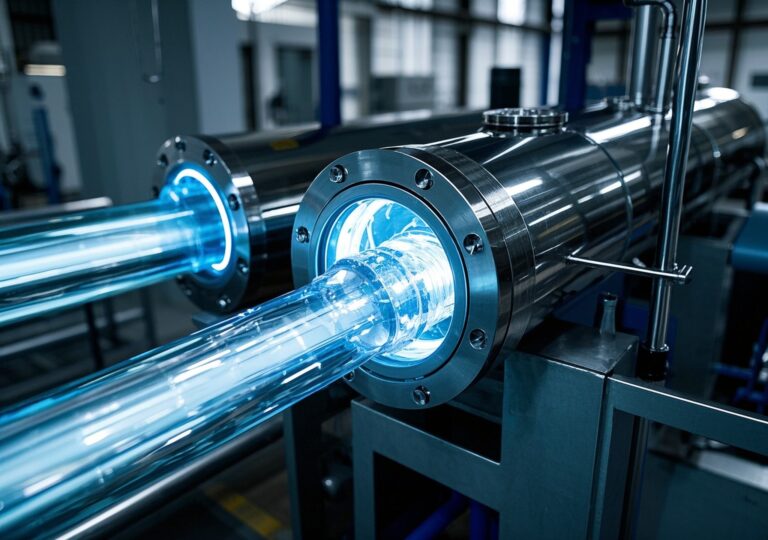

1.4 Cleaning and Disinfection Components

Ultrafiltration systems incorporate robust cleaning protocols, including chemical CIP and ultraviolet (UV) sterilization units to prevent biofouling and ensure disinfection compliance. UV technology particularly addresses microbial contaminants post-filtration without adding residual chemicals.

Scope: Inline UV disinfection modules handle flows from 1 to 100 cubic meters per hour, suitable for continuous commercial operations.

Benefits: Meets stringent water quality standards, ensures regulatory compliance, and safeguards downstream processes.

2. Manufacturing Expertise and Quality Assurance

Proven manufacturers of ultrafiltration systems leverage decades of experience and continuous innovation to deliver equipment that meets rigorous industrial standards. Their research develops membranes with optimized pore size distribution and fouling resistance, advancing separation efficacy and energy efficiency.

Quality control spans raw material validation, stringent fabrication processes, and performance testing under simulated operational conditions. Such diligence ensures system reliability and maximizes the return on investment for industrial and commercial users.

3. Diverse Application Scenarios of Ultrafiltration Technology

3.1 Seawater Desalination Pretreatment

Ultrafiltration serves as a crucial pretreatment step before reverse osmosis in desalination plants. It effectively removes particulate matter and microbial load, protecting the sensitive RO membranes. In my consultancy projects for coastal power plants, UF pretreatment reduced membrane fouling rates by over 30%, significantly lowering maintenance downtime and operational costs.

3.2 Portable Drinking Water Systems

Deploying compact ultrafiltration units has proven essential in disaster relief and remote commercial sites. For instance, in a recent case involving a temporary mining camp, a mobile UF system reliably supplied over 5,000 liters daily of potable water, meeting WHO guidelines and improving worker health and productivity markedly.

3.3 Space and Extreme Environment Water Treatment

Advanced ultrafiltration is a candidate technology for off-planet applications, such as potable water regeneration onboard spacecraft. The precise microbial removal and low chemical use align with closed-loop life support systems where water recovery and purity are paramount. Although still in development, these applications underscore the versatility of UF technology.

4. Summary of System Advantages and Industry Trends

| Feature | Benefit | Applicable Scale |

|---|---|---|

| High removal efficiency | Reliable elimination of pathogens and particles ≥ 0.01 micron | Small to large industrial & commercial units |

| Chemical-free operation | Eco-friendly, reducing chemical handling and residues | All scales, especially sensitive food and pharma sectors |

| Modular scalability | Adaptable capacity to evolving demand | Startups to large-scale water treatment plants |

| Robust membrane options | Polymeric for general use, ceramic for harsh wastewater | Industrial wastewater & municipal reuse applications |

According to a Grand View Research industry report, the global ultrafiltration market is projected to grow at a CAGR of 5.2% between 2025 and 2030, reflecting escalating demand in both industrial and commercial sectors. This trend aligns with tightening environmental regulations and the push for sustainable water reuse practices.

Conclusion: Optimizing Water Quality with Expertise-Backed Ultrafiltration

Integrating ultrafiltration water treatment systems within commercial and industrial water management frameworks offers measurable benefits, including enhanced water safety, operational efficiency, and regulatory compliance. Selecting a system that matches the scale and specific requirements of your facility is critical.

My practical experience confirms that partnering with manufacturers who provide modular, reliable, and service-oriented solutions results in faster ROI and fewer operational challenges. As the market evolves, ultrafiltration stands out as a future-proof option for sustainable water treatment.

References

- Grand View Research – Ultrafiltration Market Size & Share | Industry Report, 2030

- Research and Markets – Ultrafiltration Market by Application and End User, 2025-2030

- Emergen Research – Ultrafiltration Market Size, Trend & Demand Till 2032

- Fact.MR – Ultrafiltration Market Forecast to 2033

- Allied Market Research – Ultrafiltration Market Research, 2031

- MarketsandMarkets – Hollow Fiber Ultrafiltration Market Forecast to 2030

- Future Market Insights – Ultrafiltration Membranes Market Forecast, 2025-2035