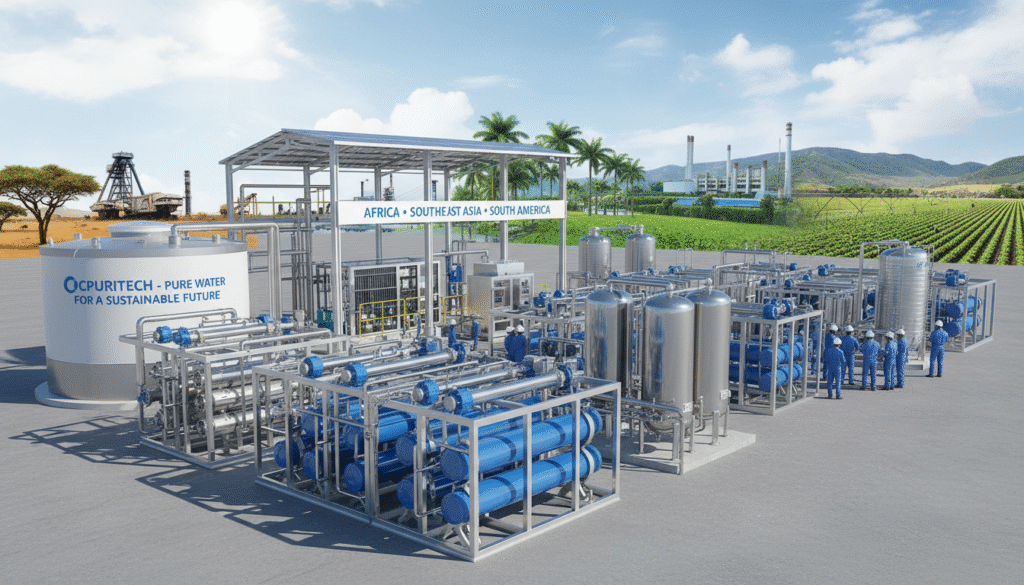

In today’s fast-evolving industrial landscape, water serves as a critical resource, demanding efficient purification and treatment solutions. Advanced water treatment plant systems play an essential role in optimizing production, ensuring regulatory compliance, and enhancing environmental sustainability. For industries in emerging markets such as Africa, Southeast Asia, and South America, these systems are not only vital for operational efficiency but also for safeguarding regional water security.

This article provides a comprehensive overview of advanced industrial water treatment technologies, market trends, innovative product solutions, and real-world applications. It also highlights sustainable practices and environmental commitments shaping the future of water treatment plants worldwide, based on both authoritative global data and practical industry insights.

Company and Industry Background

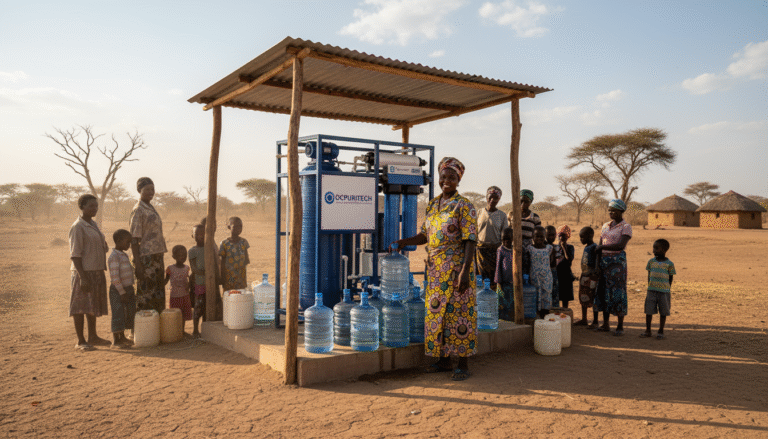

With over 14 years of dedicated experience, companies like Ocpuritech have established themselves as leaders in the manufacturing of industrial water purification equipment. Operating from two modern factories in Guangzhou and Jiangmen, covering more than 10,000 square meters, they epitomize a blend of advanced manufacturing capabilities and extensive research & development strength.

The core philosophy revolves around providing high-quality, cost-effective water treatment solutions tailored to diverse industrial applications, spanning from agriculture and pharmaceuticals to beverage production and semiconductor manufacturing. This commitment reflects a deep sense of responsibility toward environmental protection and public health.

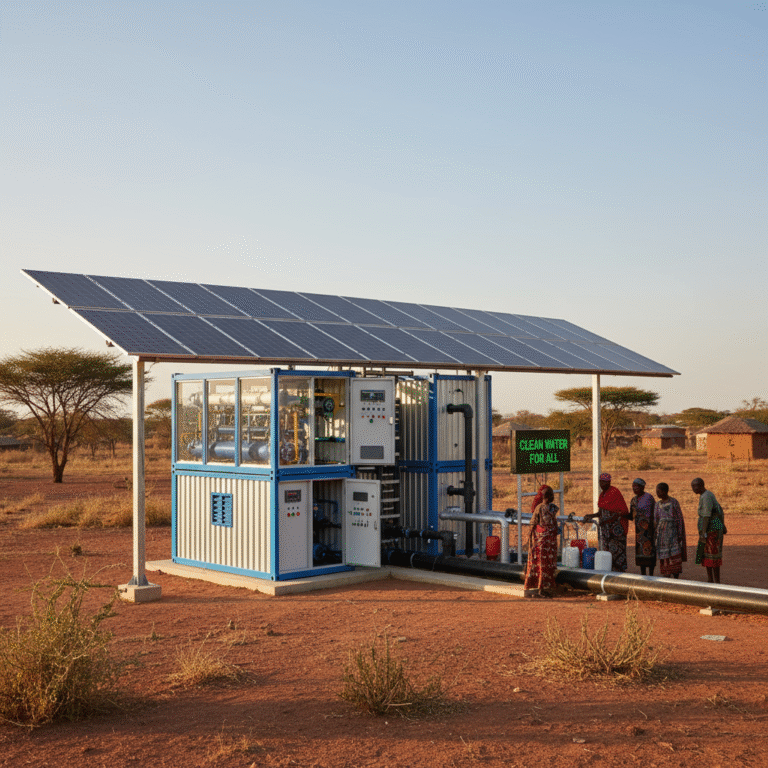

Globally, approximately 80% of industrial wastewater is discharged untreated, a figure that rises to nearly 95% in many low-income countries, particularly in Africa, Southeast Asia, and South America. According to the United Nations Environment Programme (UNEP) and the World Health Organization (WHO), this untreated discharge poses severe risks to local water security, exacerbating pollution, ecosystem damage, and public health concerns. This backdrop underscores the urgent demand for reliable and advanced water treatment plants in these emerging markets.

Comprehensive Product Series for Industrial Water Purification

Advanced industrial water treatment plants incorporate a variety of technologies to meet diverse purification needs. Below is a detailed examination of key product types and their specific applications:

- Reverse Osmosis (RO) Systems: Core to many water treatment plants, RO systems effectively remove dissolved salts, organics, and microbial contaminants. Variants include seawater desalination units, brackish water treatment, and remote-controlled RO setups. These systems excel in industries requiring high-purity water such as beverage production and pharmaceutical manufacturing.

- Ultrafiltration (UF) Systems: Used primarily for particulate and colloidal removal, UF membranes provide a robust pretreatment barrier protecting downstream RO membranes and enhancing overall plant performance.

- Electrodeionization (EDI) Systems: For ultra-pure water demands—common in semiconductor, pharmaceutical, and photovoltaic industries—EDI offers continuous ion removal without chemical regenerants. This technology helps maintain ASTM D5127 Type I ultrapure water standards, achieving resistivity up to 18.2 MΩ·cm and ultra-low Total Organic Carbon (TOC) levels below 50 ppb.

- Pretreatment and Softening Systems: Sand filters, carbon filters, and water softeners ensure removal of suspended solids, chlorine, and hardness ions. This step guarantees prolonged system life and optimized downstream treatment efficacy.

Through these components, modern water treatment plants cater to diverse industrial water needs, ranging from boiler feedwater and recycled water to production-grade purified water.

Technological Innovation and Competitive Advantages

Continuous advancements in water treatment technologies have significantly enhanced plant efficiency and energy savings. For instance, in seawater desalination via reverse osmosis (SWRO), the specific energy consumption has decreased substantially over the past two decades thanks to membrane material improvements and highly efficient energy recovery devices.

Data from the International Desalination Association (IDA) indicates that SWRO plants once needed more than 5 kWh/m³ in the 1990s, but modern installations operate below 3 kWh/m³, with cutting-edge systems even reaching as low as 1.58 kWh/m³. This roughly 60-70% reduction in energy use exemplifies how innovation leads to cost-effective and sustainable operations.

| Technology | Typical Energy Consumption (kWh/m³) | Main Advantages |

|---|---|---|

| 1990s SWRO Plants | >5 | Basic membrane tech, low energy recovery |

| Modern SWRO Plants | <3 | Advanced membranes, improved energy recovery devices |

| Cutting-edge SWRO Systems | ≈1.58 | Next-gen membranes, optimized energy recovery, reduced environmental footprint |

In my experience managing water treatment projects across Southeast Asia, integrating these next-generation technologies dramatically reduced operational costs by up to 30% while improving system uptime and reliability. Particularly for remote industrial sites, such energy efficiency translates into significant savings with a faster return on investment.

Industry Status and Market Outlook

The global industrial water treatment equipment market is on a robust growth trajectory. MarketsandMarkets forecasts that this market will grow from approximately $70.3 billion in 2023 to nearly $96.3 billion by 2028, with a compound annual growth rate (CAGR) of 6.5%. The Asia-Pacific region, including Southeast Asia, leads growth due to rapid industrialization and infrastructure development.

Africa and South America also exhibit increasing demand driven by urban growth, emerging industries, and heightened environmental regulations. These regions require scalable, reliable water treatment plants to support sustainable development. Companies offering modular and energy-efficient solutions are particularly well-positioned to capitalize on these expanding opportunities.

From my perspective working with clients in emerging economies, the ability to customize solutions, provide strong after-sales support, and source spare parts locally substantially enhances customer satisfaction and project success rates. Leveraging such strategies ensures longevity and trust in water treatment plant installations.

Manufacturing and R&D Strengths

Modern water treatment companies prioritize robust manufacturing and innovation capabilities as cornerstones of quality assurance. The presence of standardized factories equipped with automated production lines and rigorous quality control protocols guarantees consistent product performance.

Investments in research and development fuel continual enhancements in membrane technologies, system automation, and monitoring capabilities. Collaborative partnerships with academic institutions and technology providers drive cutting-edge solutions, ensuring that products meet evolving industry standards and client specifications.

In one project deploying an EDI ultrapure water system for a pharmaceutical plant, meticulous R&D tailoring ensured water quality remained stable at 18.2 MΩ·cm resistivity and TOC levels under 10 ppb over years of operation. This stability met stringent ASTM D5127 standards crucial for the client’s manufacturing process reliability.

Customer Case: Sustainable Water Treatment Success in Southeast Asia

In a recent project supporting a beverage factory in Southeast Asia, deploying an integrated water treatment plant featuring ultrafiltration and reverse osmosis systems resulted in 40% water reuse and a 25% reduction in wastewater discharge volume. These improvements not only enhanced sustainability but also significantly lowered water procurement costs.

This project benefited from careful site assessment, customized pretreatment selection, and integration with existing production processes. Continuous monitoring and remote control capabilities allowed rapid issue resolution and optimized operational parameters.

Commitment to Environmental Sustainability

Protecting the environment is more than a corporate slogan; it is a driving principle behind every design in advanced water treatment plants. The adoption of energy-efficient technologies, chemical-free regeneration processes (such as in EDI systems), and waste minimization strategies contribute to reducing industrial water footprints.

By aligning with internationally recognized standards and promoting water reuse, these systems support circular water economies crucial in water-stressed regions. As stated by industry leaders, “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.”

Engage and Optimize: Custom Solutions for Your Industrial Water Needs

Selecting the right water treatment plant system requires a thorough understanding of your unique production processes, water quality requirements, and sustainability goals. Trusted partners with a strong technical foundation and proven track record, such as Ocpuritech, offer tailored consultation services and comprehensive after-sales support.

We encourage industrial decision-makers and procurement specialists to connect with experts who can assess site-specific conditions, design scalable water treatment solutions, and ensure seamless integration. Customized quotations, remote monitoring options, and modular expansions are available for optimal operational agility.

Frequently Asked Questions

Q1: How significant is untreated industrial wastewater in emerging markets?

A1: According to UNEP and WHO, about 80% of industrial wastewater globally is discharged untreated, rising up to 95% in low-income countries, which severely affects local water security and ecosystem health.

Q2: What market growth is expected for water treatment equipment in the next decade?

A2: The global industrial water treatment market is projected to reach nearly $96.3 billion by 2028, growing at a CAGR of 6.5%, with Asia-Pacific showing the strongest growth momentum.

Q3: What are the main advantages of Electrodeionization (EDI) over traditional ion exchange?

A3: EDI delivers continuous ultrapure water production without chemical regenerants, offering higher water quality stability, lower operational costs, smaller footprint, and reduced environmental risks.

Q4: How much energy can modern SWRO plants save compared to older units?

A4: Modern seawater RO plants consume less than 3 kWh/m³, a reduction of over 40% compared to 1990s technology, with some advanced plants operating near 1.58 kWh/m³ due to innovative membranes and energy recovery devices.

Data Sources: United Nations Environment Programme (UNEP) – “Turning Waste Water into a Resource”; World Health Organization (WHO) – “Water, sanitation, hygiene, and wastewater: an overview”; MarketsandMarkets – “Industrial Water Treatment Market Global Forecast to 2028”; International Desalination Association (IDA); ASTM International – D5127 Standard.