Product Overview of Ultrafiltration Systems in Industrial Water Treatment

Ultrafiltration (UF) systems represent a crucial class of membrane filtration technology widely employed in industrial water treatment applications. These systems serve to remove suspended solids, colloidal particles, bacteria, viruses, and macromolecules from water, achieving finer purification than conventional filtration methods. The ultrafiltration membranes typically have pore sizes ranging from 0.01 to 0.1 microns, making them effective barriers against all particulate matter exceeding these dimensions.

UF technology is extensively applied across diverse sectors including mining, food and beverage processing, pharmaceutical manufacturing, cosmetics formulation, laboratory water preparation, ultrapure water generation, boiler feed water treatment, and municipal as well as surface and groundwater purification. For example, in the pharmaceutical industry, maintaining microbial and particulate control is vital to comply with stringent standards like USP and WHO requirements, while in mining operations, UF can remove suspended solids and process water contaminants to lower environmental impact.

Depending on the feedwater quality, ultrafiltration systems may treat sources ranging from river water, well water, municipal water, or industrial wastewater. This versatility makes UF an adaptable choice for pretreatment or final polishing steps in complex water treatment trains.

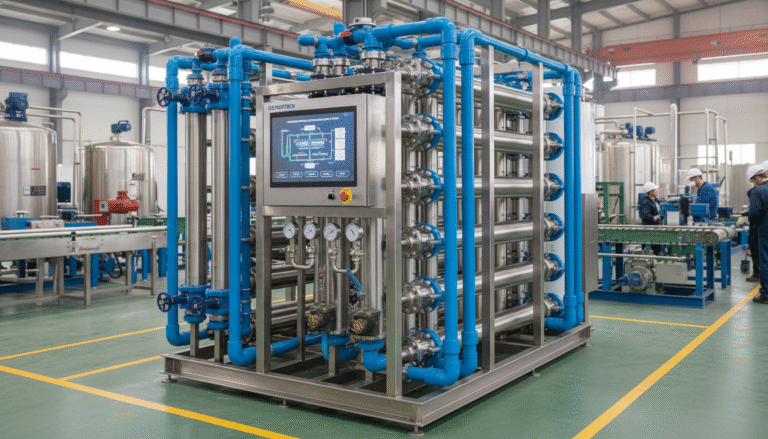

Technical Principles and Key Components of Ultrafiltration Systems

Ultrafiltration operates on the principle of pressure-driven membrane separation. Feedwater is forced through semipermeable membranes that trap suspended solids, pathogens, and high molecular weight substances, while allowing water and dissolved low molecular weight solutes to pass. The membranes are typically made from polymeric materials such as polysulfone (PS), polyethersulfone (PES), or ceramic composites for enhanced durability.

Key components of a UF system include:

- Membrane Modules: Hollow fiber, spiral wound, or flat sheet configurations designed for optimal surface area and hydraulic efficiency.

- Feed Pump: Provides the necessary pressure (usually between 1–5 bar) to drive feedwater through membranes.

- Backwash and Cleaning Systems: Automated or manual procedures to periodically remove fouling layers, using chemicals or physical methods.

- Instrumentation and Automatic Controls: Sensors for pressure, flow, turbidity, and conductivity integrated with programmable logic controllers (PLC) for system optimization and alarm management.

From my experience managing UF installations in food processing plants, the automation level directly impacts operational stability and membrane longevity. Systems with remote-control interfaces allow fine-tuned backwash scheduling, which can reduce chemical consumption by up to 30% and extend membrane life by several years.

Moreover, ultrafiltration systems often serve as pretreatment for reverse osmosis (RO) units, effectively reducing downstream fouling by removing colloidal matter that can damage RO membranes. As such, UF is indispensable in applications demanding high water purity combined with cost-effective operation.

Analyzing the Cost of Ultrafiltration Systems

Understanding the cost of ultrafiltration systems involves dissecting the total investment into several components:

- Base System Cost: This includes membrane modules, feed pumps, and primary control panels. The capacity and membrane type largely dictate pricing. For instance, hollow fiber membranes tend to be less expensive upfront but may require more frequent replacement depending on feedwater quality.

- Auxiliary Modules: These cover pre-treatment units (e.g., multimedia filters), chemical dosing systems, UV sterilizers, and post-treatment elements like activated carbon filters, which increase comprehensive treatment effectiveness.

- Installation and Commissioning: Costs related to site preparation, piping, electrical integration, and system start-up procedures.

- Operation and Maintenance (O&M): Periodic membrane cleaning, replacement, energy consumption, and labor. Membrane lifespan typically ranges from 3 to 7 years, depending on operational discipline and feedwater conditions.

In a municipal water plant project I oversaw, initial UF system costs represented approximately 20% of the total water treatment plant budget. Yet, the low energy consumption and reduced chemical use relative to conventional sand filtration led to lifecycle cost savings of up to 15% within five years. This underlines the importance of assessing total cost of ownership rather than only purchase price.

Below is a typical cost breakdown table for an industrial UF system serving a capacity of 500 cubic meters per day (m³/d):

| Cost Component | Percentage of Total Cost (%) | Remarks |

|---|---|---|

| Membrane Modules & Systems | 45% | Depends on membrane type and quality |

| Installation & Engineering | 20% | Electrical, civil works included |

| Pre/Post-treatment Units | 15% | Filters, dosing, UV systems |

| Operating & Maintenance Costs (Annualized) | 20% | Membrane cleaning and labor |

Selecting ultrafiltration technology not only hinges on upfront costs but greatly depends on feedwater characteristics and desired permeate quality. I recommend engaging stakeholders early to accurately define water quality targets to optimize system design and investment.

Performance Specifications and Quality Assurance Measures

Ultrafiltration systems must meet rigorous performance criteria to ensure treated water complies with industry standards. Typical performance indicators include:

- Turbidity Reduction: UF membranes typically achieve >99% removal of turbidity-causing particles.

- Bacteria & Virus Removal: Given membrane pore sizes ~0.01 microns, UF effectively removes bacteria (0.2–10 microns) and most viruses (0.02–0.3 microns), achieving >99.99% log removal rates.

- Suspended Solids: UF removes suspended solids larger than membrane pores, reducing solids to sub-ppm levels in permeate.

- Flux Rates and Recovery: System flux usually ranges from 50 to 100 liters/m²/hour, with recovery rates between 75% and 85%, depending on feedwater quality.

Material selection is key to ensuring safety and durability. Components in contact with purified water typically comply with NSF/ANSI 61 standards to limit chemical leaching and potential health risks. Stainless steel 316/316L is considered a benchmark for structural parts due to corrosion resistance and hygienic properties.

From a quality assurance standpoint, strict manufacturing controls include membrane integrity testing (e.g., bubble point test), physical inspections, and performance validation. In one plant I supervised, adopting ISO 22519-compliant materials and construction protocols led to zero membrane failure incidents over a three-year operational period, reinforcing system reliability.

Market and Application Scenario Analysis

The application viability of ultrafiltration systems strongly relates to the peculiarities of the source water in different regions. Understanding these characteristics helps tailor solutions for optimal efficacy.

For instance, in North China, water scarcity exacerbates pollution issues. Many shallow groundwater sources show high contamination with heavy metals and agricultural chemicals. UF systems here often function as part of advanced treatment trains to ensure compliance with drinking water standards, despite challenges posed by elevated organics and salinity [according to North China Water Quality Management Study].

In India, water bodies face organic pollution manifested through elevated Biochemical Oxygen Demand (BOD) and microbial contamination, including coliform bacteria. Ultrafiltration provides an effective microbial barrier, pivotal for downstream potable water treatment and food processing industries, as outlined by recent Central Pollution Control Board reports.

Southeast Asia encounters rapid urbanization-driven pollution with complex contamination profiles including heavy metals, pharmaceuticals, microplastics, and agricultural runoff. UF technology’s ability to remove fine particles and microorganisms positions it as a core component of urban water reclamation and industrial process water purification strategies.

My experience working on a Southeast Asian municipal water upgrade project highlights how integrating ultrafiltration reduced turbidity from 8 NTU to under 0.1 NTU, facilitating compliance with WHO guidelines for safe drinking water and significantly reducing outbreaks of waterborne illnesses.

Case Studies Demonstrating Ultrafiltration System Efficiency

To better illustrate practical ultrafiltration applications, I’d like to share several industry cases:

- Food & Beverage Processing Plant: A major juice manufacturer replaced conventional clarification with UF to improve microbial control. Result: 99.9% reduction in microbial load, enhancing product shelf life by 20%, and lowering chemical disinfectant costs by 25%.

- Pharmaceutical Facility: Implemented UF as pretreatment to a water-for-injection (WFI) system, ensuring TOC levels below 500 ppb and turbidity under 0.1 NTU, fully compliant with USP <1231> standards. The system maintained continuous operation with minimal downtime over 18 months.

- Mining Operation: Installed UF for process water recycling, achieving 85% reuse of tailings pond water, reducing freshwater intake by 30%, and mitigating environmental discharge impact.

These cases demonstrate the substantial operational improvements and cost savings achievable through well-designed UF systems adapted to specific industrial needs.

Customized Solutions and Service Support

Customization is at the core of maximizing ultrafiltration system value. Pre-treatment options such as multimedia filtration, coagulation, or antiscalant dosing enhance membrane fouling control. Post-treatment stages like UV disinfection or activated carbon adsorption complement pathogen inactivation and organic compound reduction.

Professional suppliers offer full-service scopes, including:

- System design tailored to feedwater analysis and quality requirements.

- Installation supervision and commissioning assistance to ensure operational readiness.

- Regular maintenance contracts encompassing membrane cleaning protocols and component replacement schedules.

- Remote monitoring and troubleshooting support via IoT-enabled controls, minimizing downtime.

From my projects, the incorporation of preventative maintenance services has reduced unplanned outages by an average of 40%, protecting plant production continuity.

Manufacturer Credentials and Partnership Benefits

Evaluation of ultrafiltration system suppliers includes verification of technology expertise, industry certifications (e.g., NSF/ANSI, ISO 9001), and track records of successful deployments. Manufacturers adhering to recognized standards such as NSF/ANSI 61 and ISO 22519 ensure materials and construction meet health and safety criteria critical for purified water applications.

Collaborating with experienced manufacturers often yields collaborative design programs, pilot testing, and tailored training for operator staff, enhancing system integration and performance reliability.

Comprehensive Conclusion and Investment Recommendations

Ultrafiltration systems stand out as a cost-effective, high-performance solution for diverse industrial water treatment demands. Their ability to ensure microbiological safety, reduce turbidity, and complement downstream advanced treatments makes them indispensable in modern plants.

Investment decisions should consider:

- Lifecycle operational costs balanced against initial capital expenditure.

- Local water quality challenges in the target region to customize treatment trains effectively.

- Supplier experience and quality assurance adherence to safeguard long-term system performance.

In my consultancy practice, I advocate for upfront pilot testing of site-specific feedwater, combined with modular system designs allowing phased capital deployment and easier upgrades, ensuring optimized returns on investment.

References of Authoritative Data

- U.S. Validation Services – Pharmaceutical Water Categories – USP Guidelines

- Water Quality Association – Reverse Osmosis Fact Sheet

- U.S. EPA WaterSense Specification for Point-of-Use Reverse Osmosis Systems

- NSF/ANSI 61 Drinking Water System Components – Health Effects Standard Overview

- North China Water Quality Management Study Summary Report

- Water Quality Monitoring in India – Central Pollution Control Board Reports

- Asian Development Bank – Southeast Asia Rivers Pollution Analysis

</1231>