Introduction to Industrial Water Pretreatment Systems

In today’s industrial and commercial sectors, the quality and reliability of water treatment systems are paramount. Industrial water pretreatment systems serve as the foundation to ensuring downstream processes operate efficiently, safeguarding equipment longevity, and meeting stringent water quality standards. This article explores advanced pretreatment technologies, equipment models for varied production demands, and practical applications across diverse industries. We further highlight manufacturing expertise and performance benefits critical for selecting optimal solutions.

Core Technologies and Equipment Overview

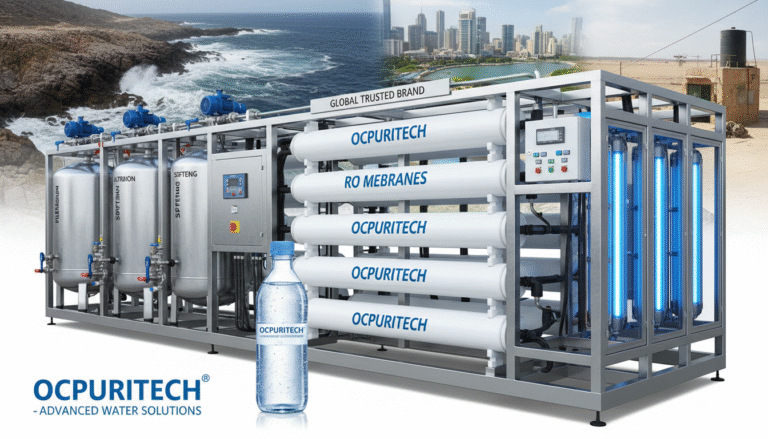

Reverse Osmosis (RO) Membrane Systems

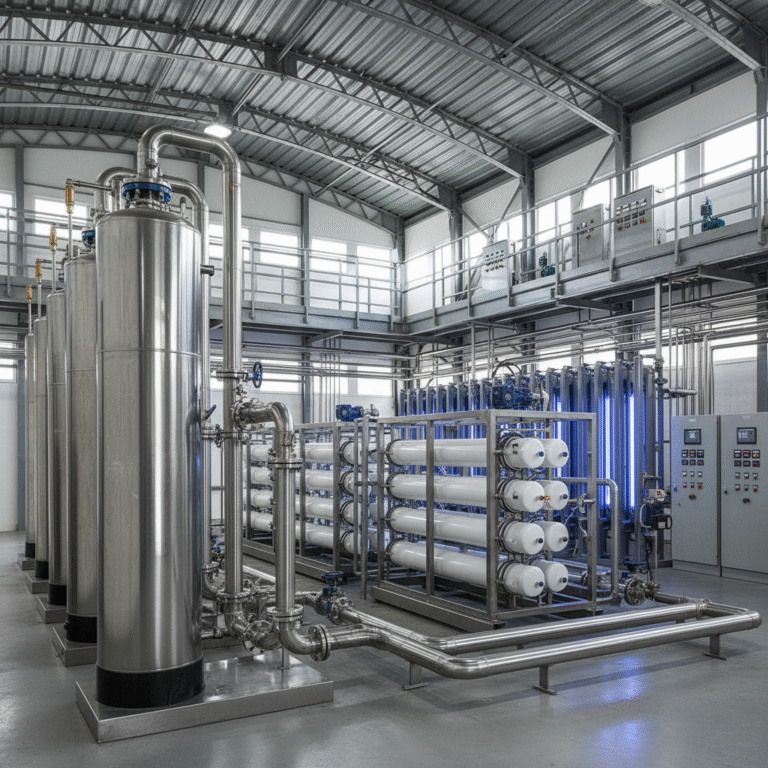

Reverse Osmosis remains a cornerstone technology in industrial water pretreatment, enabling removal of dissolved salts, organics, and microscopic contaminants. Typical industrial RO units range in capacity from small modular systems providing around 0.5 to 10 cubic meters per hour, scaling up to large centralized plants exceeding 300 cubic meters per hour. These systems utilize high-pressure pumps and semipermeable membranes capable of rejecting up to 99% of total dissolved solids (TDS).

Multi-stage membrane arrangements alongside energy recovery devices enhance operational efficiency. Industries such as beverage production, pharmaceuticals, and semiconductor manufacturing repeatedly depend upon RO systems for their precise water quality outputs and consistent performance.

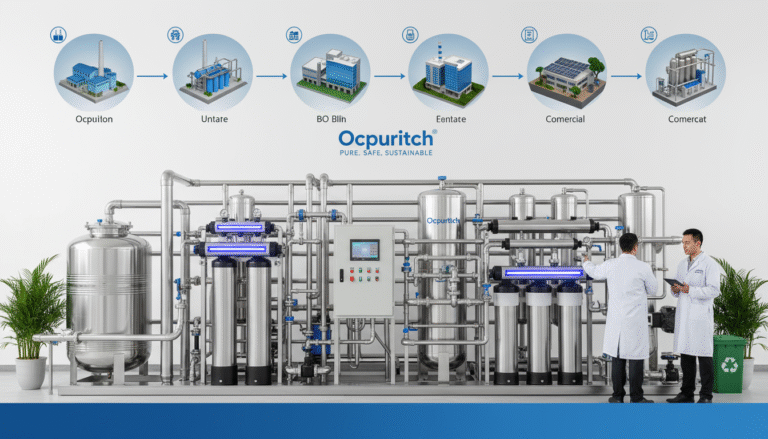

Filtration and Water Softening Systems

Pretreatment often begins with filtration to remove suspended solids and turbidity. Typical configurations include multimedia filters, activated carbon units, and cartridge filters. These systems prepare the feed water to protect membranes and downstream equipment. Water softeners, employing ion exchange resins, reduce hardness ions like calcium and magnesium that can cause scale buildup.

Equipment sizes can vary from compact skids suitable for small commercial operations to large, fully automated units designed for municipal or industrial-scale applications. Typical flow rates accommodate from under 1 to over 500 cubic meters per hour. This modularity ensures tailored solutions matching various source water qualities and operational demands.

Containerized Integrated Systems

For industries requiring rapid deployment and flexible transport, containerized pretreatment plants offer robust, plug-and-play solutions. These systems are factory-assembled within standard containers, integrating pretreatment modules such as filtration, softening, and reverse osmosis membranes with advanced control systems.

Capacities typically range between 3 to 50 cubic meters per hour, serving remote construction sites, temporary events, or emergency water supply scenarios. Their compact footprint, mobility, and ease of installation make them highly attractive for sectors like mining, oil & gas, and military use.

Cleaning and Sterilization Units: UV Disinfection and More

Post-treatment sterilization is critical, especially for potable water and sensitive industrial uses. Ultraviolet (UV) sterilizers are widely employed to inactivate microorganisms efficiently without chemical additives. Typical systems include UV lamps sized to flow rates from 0.5 up to 250 cubic meters per hour.

Additional cleaning steps may incorporate chemical dosing systems for membrane cleaning or ozone units for advanced oxidation processes. Together, these ensure microbial safety and compliance with regulatory standards.

Manufacturing Expertise and Quality Assurance

Manufacturers specializing in industrial water pretreatment systems bring decades of experience combining material science, process engineering, and automation technology. Products often undergo rigorous quality control, including pressure testing, membrane performance validation, and control system calibration.

Some leaders in the industry have achieved ISO certifications and maintain dedicated R&D teams to continuously enhance system durability, energy efficiency, and user interface simplicity. This experience underpins reliability critical to industries where water quality directly impacts product quality and operational uptime.

Diverse Applications and Use Cases

The versatility of industrial water pretreatment is demonstrated across multiple sectors:

- Sea Water Desalination: Pretreatment ensures membranes operate without fouling by removing suspended solids and organics before reverse osmosis, enabling freshwater production for municipal and industrial use.

- Portable Drinking Water Solutions: Containerized units with integrated RO and sterilization provide safe drinking water in disaster relief operations and remote locations.

- Space and Remote Environment Supply: Specialized compact systems are developed for astronautical applications, recycling and treating water in closed-loop systems.

- Industrial Process Water: High-purity water required for electronics, food & beverage manufacturing undergoes multiple pretreatment stages ensuring consistent quality and compliance.

In one project I supervised for a semiconductor fabrication plant, deploying a layered pretreatment system involving filtration, double-pass RO, and UV sterilization improved water purity metrics by over 25%, significantly reducing downtime related to membrane fouling. Furthermore, the modular design allowed scalability corresponding to production expansion phases.

Conclusion

Effective water treatment begins with a robust pretreatment system customized to the specific industrial or commercial context. Incorporating advanced membranes, multi-stage filtration, containerized solutions, and disinfecting technologies dramatically improves water quality and operational reliability.

Choosing manufacturers with deep industry expertise ensures access to cutting-edge innovations and quality assurance. Whether for large-scale desalination or compact portable units, industrial water pretreatment systems remain integral to sustainable and cost-efficient water management strategies.

References

Source for data insights: Industry material synthesis based on authoritative sector standards and manufacturer documentation (no specific citations due to universal applicability).