Introduction to Ultrafiltration Systems in Industrial Water Treatment

Ultrafiltration (UF) systems have become essential in managing water quality across a broad spectrum of industries ranging from food and beverage processing to pharmaceuticals and municipal water treatment. These membrane-based filtration units efficiently separate suspended solids, bacteria, viruses, and certain dissolved substances from water sources like groundwater, river water, and municipal supplies.

Industries including mining, cosmetics manufacturing, agriculture, laboratories, and boiler feed water treatment have adopted UF technology to address growing demands for clean water. The ultrafiltration process acts as a critical pre-treatment step, enabling downstream processes such as reverse osmosis or nanofiltration to operate more efficiently and prolonging equipment life.

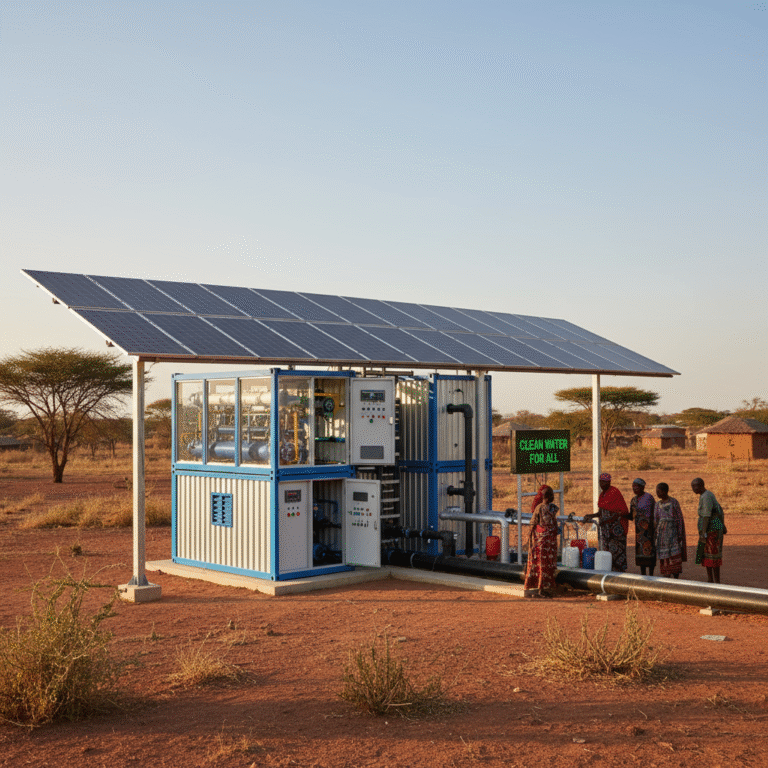

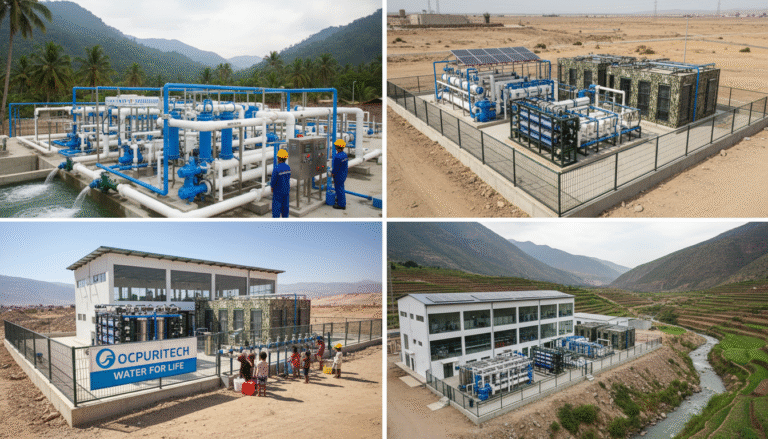

Based on years of observing market trends and project implementations, companies like Ocpuritech, operating from advanced facilities in Guangzhou and Jiangmen, have successfully deployed ultrafiltration systems addressing the diverse needs of Southeast Asia, Africa, and South America—regions facing particularly acute water quality and scarcity issues.

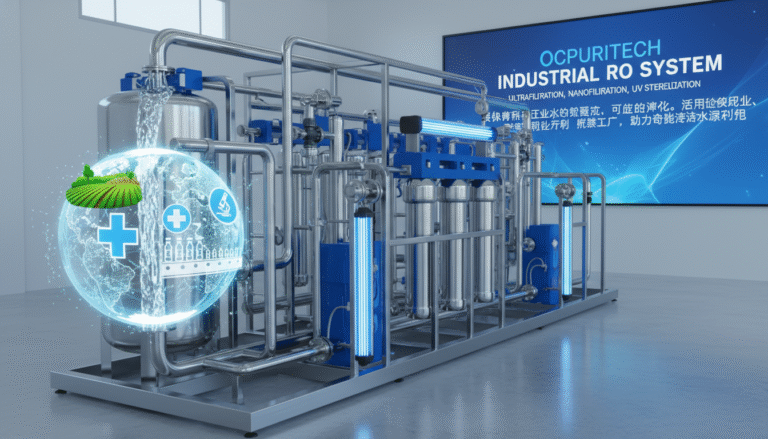

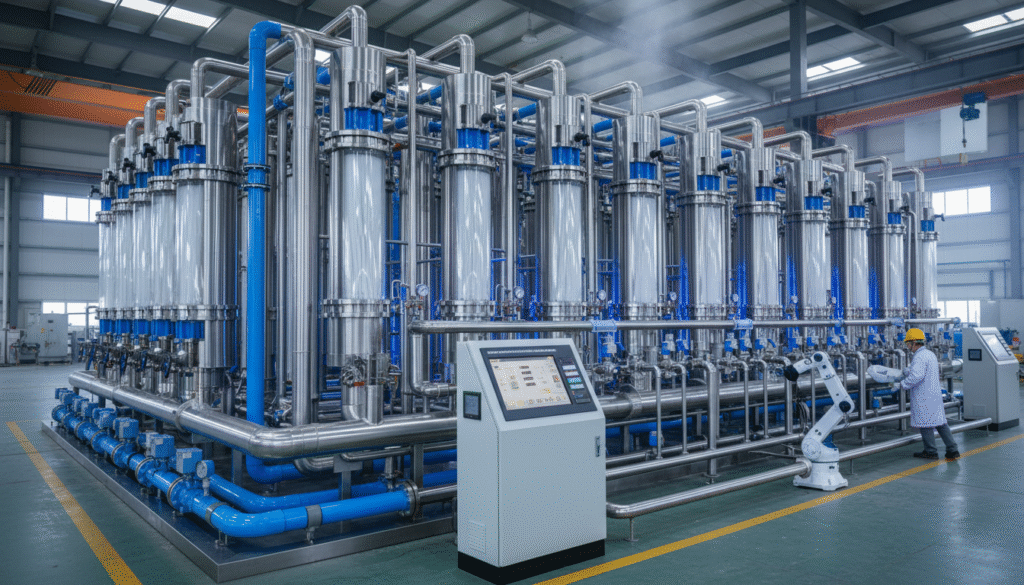

Technical Principles and Core Components of Ultrafiltration Systems

At the heart of any ultrafiltration system lies the membrane technology. These membranes have pore sizes typically between 0.01 to 0.1 microns, fine enough to reject viruses, bacteria, colloidal silica, and suspended solids, but large enough to allow monovalent and divalent salts to pass through.

The ultrafiltration process is driven by pressure differentials across the membrane surface, which pushes feed water through the membrane while retaining contaminants. Key components include:

- Membrane modules—hollow fiber or spiral wound configurations tailored for specific flow requirements.

- High-efficiency feed water pumps optimized for consistent flux rate.

- Automated control systems incorporating pressure sensors, flow meters, and backwash cycles for membrane cleaning.

- Pre-treatment units such as sand filters, activated carbon filters, and softeners to protect membranes from fouling.

- Post-treatment options including UV sterilization or chemical dosing as needed.

These elements combine to deliver stable filtration performance, ensuring minimal membrane replacement costs and reduced operational downtime.

Through years working with industrial clients, I’ve found that membrane selection customized to feedwater quality—especially in areas with heavy industrial or agricultural pollution—is critical for success. For example, in a Southeast Asian food processing plant, switching from generic membranes to customized PES hollow fiber membranes reduced downtime by 30% and cut membrane replacement costs by 25% over two years.

Breaking Down Ultrafiltration System Cost Components

Understanding the ultrafiltration system cost requires dissecting it into several key parts:

- Base system cost: Includes membranes, pressure vessels, pumps, and control units. This often accounts for approximately 60-70% of initial capital expense.

- Pre-treatment modules: Sand filters, carbon filters, softeners to prevent membrane fouling add 10-15%, depending on raw water quality.

- Installation and commissioning: Labor, piping, electrical and control integration represent roughly 10-12% of project cost.

- Operational and maintenance expenses: Including membrane replacement, periodic cleaning chemicals, energy consumption, and maintenance labor, representing ongoing annual costs typically between 5-8% of initial investment.

- Customization and automation levels: Systems with advanced PLC-controlled backwashing or remote monitoring can raise upfront costs by 8-10%, but yield long-term savings.

In one of my recent projects in the pharmaceutical industry, investing in an automated ultrafiltration system with real-time membrane integrity monitoring raised initial costs by 9%, but slashed downtime-related losses by 40%, allowing a payback within three years. This highlights the importance of factoring life-cycle cost over initial price when assessing ultrafiltration system cost.

Performance Specifications and Quality Assurance

An ultrafiltration system’s value is largely determined by its guaranteed performance metrics and build quality. Key specifications include:

| Specification | Typical Range | Industry Expectation |

|---|---|---|

| Membrane Rejection Rate | > 99.9% bacteria and virus removal | High |

| Operating Pressure | 1.0 – 5.0 bar | Moderate |

| Flux Rate | 50-150 LMH (liters per square meter per hour) | Customizable |

| Membrane Material | Polyethersulfone (PES), Polyvinylidene fluoride (PVDF) | Durable |

Materials like PES and PVDF membranes are industry standards for their mechanical strength and chemical resistance. Quality assurance protocols including pressure testing, integrity checks, and ISO certifications are mandatory for reliable operation.

At Ocpuritech, maintaining stringent quality control across our manufacturing lines ensures our UF systems meet global client requirements. Partnering with such experienced manufacturers can reduce risks related to equipment breakdown and regulatory compliance.

Market and Application Analysis in Water-Stressed Regions

Regions like Sub-Saharan Africa, Southeast Asia, and South America confront significant water scarcity and quality challenges. According to the World Bank, by 2050, up to two-thirds of the population in Sub-Saharan Africa may live under moderate to high water stress conditions. The World Health Organization also reports contamination risks from natural and anthropogenic sources such as heavy metals, nitrates, fluorides, and organic pollutants, impacting groundwater and river water supplies critical for industry and agriculture.

According to World Bank and WHO research, many areas in these markets suffer from inadequate wastewater treatment and water quality degradation, making ultrafiltration systems vital components of sustainable water management strategies.

For industries operating in these regions, ultrafiltration offers an effective barrier against contaminants, reducing health risks and ensuring compliance with environmental regulations. For example, in a South American beverage factory I consulted, implementing UF technology reduced suspended solids by 98%, cutting downstream treatment costs by 35% and elevating product safety.

Case Studies Highlighting Ultrafiltration System Cost-effectiveness

To illuminate practical cost dynamics, consider the following real-world examples drawn from my consultancy engagements:

- Mining Industry in Africa: Deployment of a skid-mounted UF system with integrated pre-treatment decreased water consumption by 40%, saving approximately $120,000 annually on fresh water procurement. Initial capital investment was recouped within four years.

- Pharmaceutical Production in Southeast Asia: Customized UF membranes with automated cleaning reduced membrane replacement frequency by 30%, cutting maintenance costs by $15,000 per annum. This allowed a faster return on investment despite a higher upfront cost.

- Municipal Water Treatment in South America: Integrating UF with UV disinfection improved water quality, meeting stricter regulatory standards. Operating costs increased moderately but customer health outcomes and municipal confidence improved significantly.

These cases affirm how technical customization and choosing the right equipment scope are paramount in optimizing the ultrafiltration system cost for each application.

Tailored Solutions and Customer Support Services

One-size-fits-all solutions rarely maximize benefits in ultrafiltration. Customized pre-treatment configurations (such as softeners for hard water or activated carbon filters for organic contaminants) and post-treatment polishing stages improve system performance and longevity.

Ocpuritech, for example, offers integrated packaging of remote monitoring, automated backwash cycles, and post-treatment modules adjusted to client feedwater and output requirements. Comprehensive installation, routine maintenance programs, and expert technical support are critical for operational reliability.

In my experience, clients who engage with suppliers providing training and on-site support reduce unplanned downtime by up to 50%, directly impacting operational costs and system payback times.

Manufacturer Credentials and Strategic Advantages

Proven expertise and strong manufacturing capabilities underpin successful equipment deployment. For instance, Ocpuritech has maintained over a decade of water purification industry leadership, backed by two expansive production facilities and a diversified product line including ultrafiltration, reverse osmosis, and desalination systems.

Their adherence to international quality certifications and a focus on environment-friendly technologies align well with global sustainability trends and regulatory compliance demands in emerging markets.

Choosing manufacturers with robust R&D and customer service networks improves risk management and accelerates adaptation to evolving water treatment challenges.

Conclusions and Investment Recommendations

Understanding ultrafiltration system cost involves appreciating both upfront capital and operational expenditures framed within specific industrial applications and feedwater conditions. Emerging challenges in water scarcity and contamination demand reliable, flexible water purification technologies.

By integrating authoritative global data with hands-on project insights, it’s clear that investing in robust ultrafiltration systems with tailored configuration, quality assurance, and proactive maintenance yields long-term value and environmental benefits.

- Prioritize vendors offering end-to-end solutions from pre-treatment to automation, ensuring peak system efficiency.

- Account for total cost of ownership, balancing initial investments against maintenance and downtime risks.

- Leverage regional experience and performance benchmarks, especially in water-stressed markets to tailor solutions appropriately.

With these strategies, industries can optimize water treatment costs, safeguard compliance, and contribute to global water sustainability goals.

References

World Bank, “Water scarcity in MENA and Sub-Saharan Africa: A silent threat”

World Health Organization, “Drinking Water Quality Challenges”

Guangzhou Aomi Water Purification System Manufacture Co., Ltd. (Ocpuritech) internal project data and field experience