In today’s industrial landscape, the availability of clean water is paramount—not only for operational efficiency but also for environmental stewardship. As industries worldwide face mounting pressures from environmental regulations and water scarcity, the role of efficient water treatment technologies becomes critical. The ro water treatment machine stands out as a transformative solution in this context, offering high-precision filtration and sustainable water reuse capabilities.

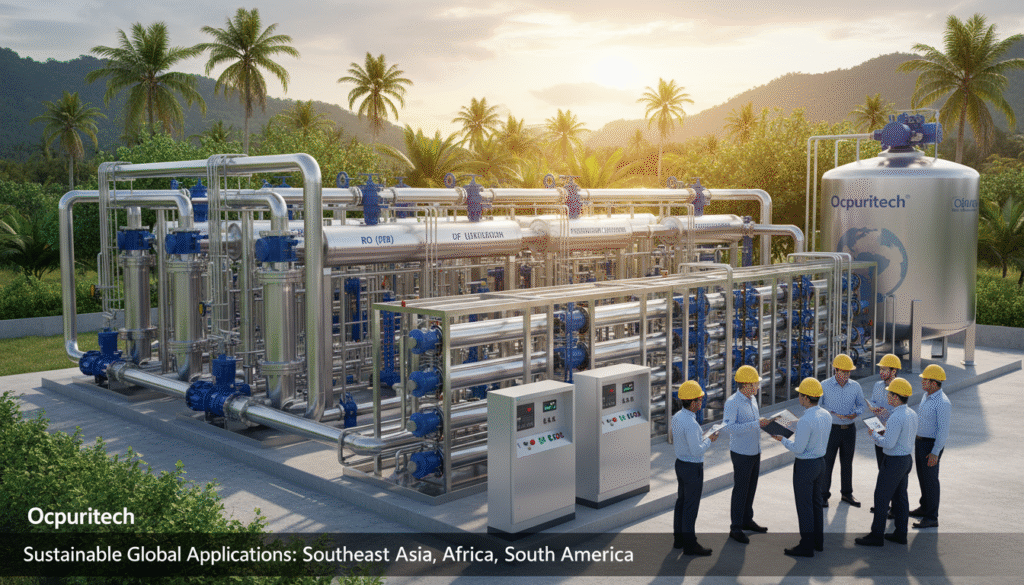

Based on over 14 years of experience in industrial water purification, companies specializing in reverse osmosis (RO) systems have revolutionized how industries manage and process water. With their roots in technology-driven innovation and an unwavering commitment to environmental responsibility, these manufacturers are reshaping the future of water processing across global markets, including Southeast Asia, Africa, and South America.

Industry Leadership and Corporate Vision in Water Treatment

The industrial water treatment sector involves handling complex challenges such as removing dissolved solids, organic compounds, and microbial contaminants from various sources like brackish water, seawater, and recycled wastewater. Leaders in this industry emphasize not just delivering effective treatment technologies but also adopting green manufacturing principles and fulfilling environmental protection duties.

With a strong foundation laid by advanced Reverse Osmosis Water treatment systems, industry pioneers have developed comprehensive portfolios covering pretreatment, ultrafiltration, nanofiltration, and ultrapure water systems. Such multi-tiered approaches reflect a profound understanding of industrial needs—ranging from boiler feed water and agricultural irrigation to pharmaceutical-grade ultrapure water production.

I recall a project where integrating a Remote Control Reverse Osmosis System in a large-scale textile dyeing factory led to a 40% reduction in water consumption while meeting stringent effluent discharge standards. This not only maximized operational cost savings but substantially mitigated environmental impact, demonstrating the pivotal role of innovative water processing technology.

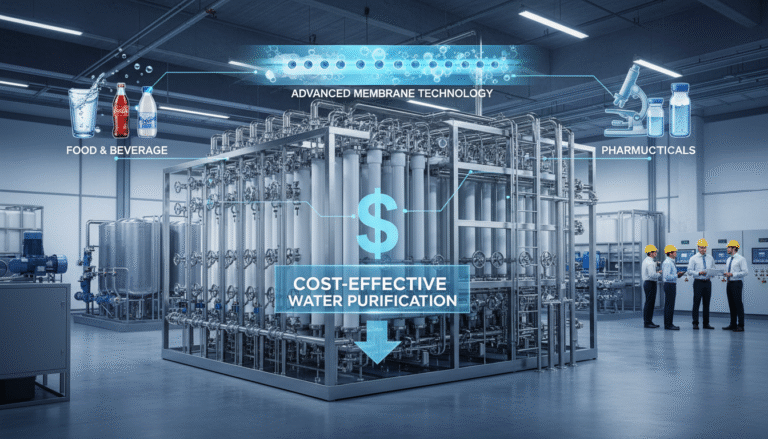

Comprehensive Product Series Tailored for Diverse Industrial Applications

The ro water treatment machine segment encompasses a variety of equipment types designed to meet specific industry requirements:

- Remote Control Reverse Osmosis System: Enables real-time monitoring and automation, ensuring optimal membrane performance and reducing downtime.

- Brackish Water RO Systems: Engineered to efficiently treat high-salinity inland waters, suitable for industrial plants located in arid regions.

- Seawater Desalination Systems: Utilizing high-rejection membranes, these systems convert seawater into potable or process water with increased energy efficiency.

- Ultrafiltration and Nanofiltration Systems: Serve as pretreatment and polishing stages, removing suspended solids and specific solutes to prolong RO membrane life.

- EDI (Electrodeionization) Ultrapure Water Systems: Deliver ultrapure water for sensitive applications such as pharmaceuticals, laboratories, and electronics manufacturing.

- Pretreatment Solutions (Sand Filter, Carbon Filter, Softeners): Protect downstream equipment by removing particulates, chlorine, and hardness ions.

I’ve personally overseen the deployment of a brackish water RO system on a plantation farm in Southeast Asia, which cut the plant’s freshwater dependency by 50% while maintaining water quality parameters vital for crop health. Such versatility underscores the adaptability of ro water treatment machine technologies across sectors.

Technological Innovations and Competitive Advantages

Advanced ro water treatment machine manufacturing integrates cutting-edge materials and digital controls that significantly outperform traditional filtration methods. Key innovations include programmable logic controllers (PLC) coupled with sensor-driven process adjustments, high rejection membranes with fouling-resistant coatings, and energy recovery devices minimizing operational costs.

| Technology Feature | Traditional Systems | Modern RO Treatment Machines |

|---|---|---|

| Energy Efficiency | ~3.0 kWh/m³ | < 2.0 kWh/m³ with energy recovery |

| Water Recovery Rate | 60-70% | Up to 85% |

| Automated Controls | Limited or manual | Remote monitoring and real-time diagnostics |

| Membrane Fouling Resistance | Standard membranes | Advanced coatings and anti-scaling pre-treatment protocols |

These improvements translate into lower maintenance expenses, increased system longevity, and optimal water savings. In a hospital project I managed, implementing these features shortened cleaning cycles by 30%, notably enhancing uptime for critical ultrapure water production.

Market Outlook and Industry Influence

The industrial water treatment market is on a vigorous growth trajectory. Forecasts predict expansion from USD 19.41 billion in 2025 to USD 34.11 billion by 2034, propelled by stringent environmental regulations and water scarcity. Leading regions such as Asia Pacific dominate the market, with Europe poised for fastest growth industrial wastewater treatment growth.

Moreover, the chemicals segment supporting these treatment systems is expanding rapidly, projected to reach USD 27.94 billion by 2033 at a CAGR of 5.5%, driven by industrial expansion and regulatory frameworks worldwide industrial water treatment chemicals market.

From my vantage point observing the Southeast Asian market, this boom is visible in rising enquiries for coastal desalination units and ultrapure water systems for new pharmaceutical hubs. This surge is also backed by international standards like NSF standards ensuring safety and performance in water treatment technology.

Manufacturing Excellence and Research Capabilities

Modern manufacturers in this sector operate from expansive, highly standardized facilities exceeding 10,000 square meters, integrating strict quality control and large-scale production lines. Collaborative R&D efforts foster innovations tailored to regional demands, improving product customization and durability.

For instance, in a recent collaboration involving a multinational agribusiness, customized pretreatment suites including sand and carbon filters were implemented to handle high-turbidity well water, enhancing the longevity of RO membranes by over 25%. Such engineering expertise underlines manufacturing competence.

Real-World Applications and Customer Success Stories

Practical implementations of ro water treatment machine solutions cover a wide spectrum from bottling plants and hospitals to textile mills and agriculture. One notable case involved installing a fully automated RO system at a beverage processor in South America. The system doubled production capacity while ensuring compliance with local drinking water standards, boosting both product quality and customer trust.

Another experience from a pharmaceutical lab project in Africa demonstrated how integrating electrodeionization units with RO pretreatment provided ultrapure water with resistivity levels exceeding 18.2 MΩ·cm, critical for drug formulation accuracy.

Commitment to Sustainability and Environmental Stewardship

Sustainability is now a cornerstone in water treatment technology development. Modern ro water treatment machines minimize chemical usage, reduce energy consumption, and maximize water recovery, aligning with global efforts to conserve freshwater resources.

Manufacturers adopt eco-friendly materials and green production processes reflecting their commitment to reduce ecological footprints. This ethos resonates with the vision that “everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system,” underscoring responsibility to protect the environment.

Get in Touch: Tailored Water Treatment Solutions for Your Needs

With expertise covering a broad water treatment spectrum, from industrial wastewater to ultrapure water production, technology providers stand ready to assist businesses in Southeast Asia, Africa, South America, and beyond. Whether you require brackish water systems, seawater desalination plants, or customized pretreatment solutions, the focus remains on delivering value-driven, sustainable outcomes.

Engage with leading specialists to explore how advanced ro water treatment machine technology can elevate your water quality, optimize costs, and meet regulatory demands. Customized solutions backed by advanced facilities and a dedicated technical team ensure your industrial water purification needs are met with precision.

FAQ

Q1: What industries benefit most from ro water treatment machines?

RO water treatment machines serve a wide range of industries including pharmaceuticals, food and beverage, agriculture, textile, cosmetics, hospitals, and municipal water treatment facilities requiring high-purity water.

Q2: How do RO systems help combat water scarcity?

RO systems enable high water recovery rates by efficiently treating brackish or wastewater, enabling reuse, and reducing dependency on freshwater sources, which is vital in water-scarce regions.

Q3: What are the main components in an industrial RO water treatment system?

The main components include pretreatment units (sand filters, carbon filters), high-pressure pumps, RO membranes, energy recovery devices, and control automation units.

Q4: How often should RO membranes be replaced?

Membrane life depends on feedwater quality and maintenance but generally spans 3 to 5 years. Proper pretreatment significantly extends membrane longevity.

Q5: Can RO systems be remotely monitored?

Yes, modern RO systems often incorporate remote control and monitoring capabilities using PLCs and IoT sensors for real-time operational management.

Q6: What energy-saving technologies are integrated into modern RO machines?

Energy recovery devices, optimized pump designs, and automated process controls reduce power consumption by recovering pressure energy and minimizing waste.

Q7: Are RO water treatment machines compliant with international safety standards?

Reputable systems meet or exceed standards such as those established by NSF for drinking water safety and treatment performance.

Q8: What is the typical water recovery rate achievable with modern RO systems?

Modern systems usually achieve 75-85% recovery, significantly improving over older technologies that only managed 60-70%.

Q9: How does pretreatment impact the performance of RO systems?

Pretreatment removes particulates, chlorine, and hardness that can foul or damage RO membranes, ensuring consistent performance and reducing downtime.

Q10: What markets are currently driving RO water treatment system demand?

The Asia Pacific region leads demand due to rapid industrialization, with growing markets in Southeast Asia, Africa, and South America focusing on sustainable water use and industrial compliance.