Advanced Commercial and Industrial Water Treatment Systems: Technology, Applications, and Versatility

Water treatment equipment is pivotal in addressing the diverse and demanding requirements of industrial and commercial sectors. From treating seawater for desalination to preparing potable water for remote locations, these systems must provide reliable, efficient, and scalable solutions. This article presents a comprehensive overview of the core water treatment technologies, including reverse osmosis (RO) membrane systems, filtration and softening units, containerized modular solutions, and advanced disinfection methods. It also highlights typical operational capacities, technical attributes, and wide-ranging industrial applications.

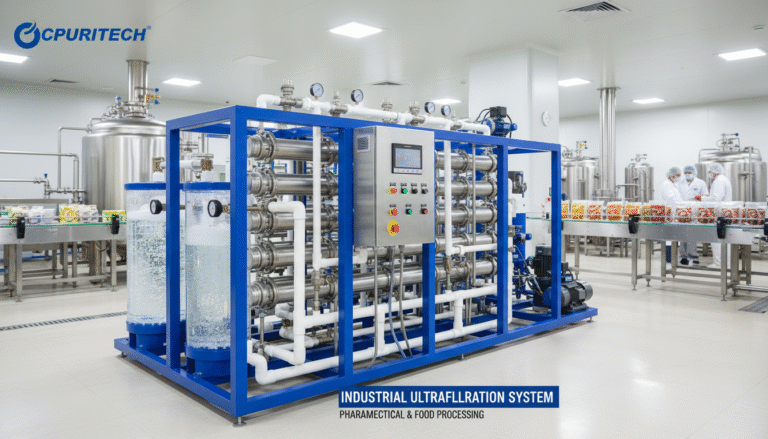

Reverse Osmosis (RO) Membrane Systems: The Heart of Modern Water Treatment

Reverse osmosis membranes are the cornerstone for producing high-purity water in both commercial and industrial workflows. They differ mainly in scale and configuration, enabling tailored solutions for varied treatment demands.

- Technical Parameters: RO systems typically operate under pressures between 4–20 bar, featuring membrane elements with rejection rates exceeding 99% for salts, organics, and microorganisms. The membranes are constructed from high-performance polyamide thin-film composites to withstand harsh feedwater conditions, including seawater salinity.

- Capacity Range: Products span from small-scale units delivering 100–1,000 liters per hour, ideal for point-of-use water purification, to large industrial installations offering above 10,000 liters per hour for plant-wide potable or process water requirements.

- Applications: These systems are indispensable in seawater desalination plants, semiconductor industry ultrapure water production, pharmaceutical manufacturing, and food & beverage processing.

- Performance Advantages: State-of-the-art membranes provide high flux with low fouling propensity, facilitating extended operational cycles. Their modular design supports easy scale-up and maintenance.

Filtration and Softening Systems: Optimizing Raw Water Quality

Prior to RO treatment, removing suspended solids, chlorine, and hardness-causing ions is critical to protect membranes and enhance overall efficiency.

- Filtration Units: Multimedia filters and activated carbon filters capture particulates, turbidity, and certain chemical contaminants. Typical flow capacities range from 0.5 to 50 m3/h, customizable per system size.

- Water Softeners: Ion-exchange softening units effectively reduce calcium and magnesium concentrations, mitigating scaling risks in downstream equipment. These units are scalable from 0.1 m3/h for small systems to over 10 m3/h continuous operation for industrial plants.

- Applications: Widely used in boiler feedwater preparation, cooling tower makeup water conditioning, and municipal water pre-treatment.

- Benefits: Optimized feedwater quality extends membrane lifespan, reduces chemical cleaning frequency, and ensures stable operation.

Containerized Systems: Mobility with Comprehensive Integration

Containerized water treatment solutions combine multiple treatment stages into a self-contained, transportable unit. This approach offers significant installation flexibility and rapid deployment, especially beneficial in challenging environments.

- Technical Overview: Integrating pre-filtration, RO membranes, UV disinfection, and chemical dosing within standard shipping containers, these systems support plug-and-play operation and remote monitoring.

- Capacity and Scale: These modular units come in capacities ranging from 1 to 50 m3/day, effectively serving military camps, disaster relief operations, small communities, and offshore platforms.

- Applications: Ideal for seawater desalination in coastal industries, portable drinking water production, and remote site water supply scenarios.

- Advantages: Containerization reduces civil works and installation time, enhances system protection, and simplifies transportation logistics.

Cleaning and Disinfection Technologies: Ensuring Microbial Safety

Beyond physical removal, water treatment demands reliable disinfection to inhibit pathogenic contamination.

- UV Disinfection: Ultraviolet germicidal lamps effectively deactivate bacteria, viruses, and protozoa without chemical additives. UV systems are sized based on flow rate and UV dose requirements, suitable for flows between 0.5 and 100 m3/h.

- Chlorination and Ozonation: While chemical disinfectants remain common for residual control, UV systems avoid carcinogenic disinfection byproducts and maintain water taste integrity.

- Industry Use Cases: Common in drinking water treatment facilities, aquaculture, and industrial process water circuits.

- Key Benefits: UV treatment offers rapid microbial inactivation, low maintenance, and no chemical storage hazards.

Manufacturer Credentials and Quality Assurance

Producers of industrial water treatment equipment typically possess decades of expertise and invest heavily in research to advance membrane designs and system automation. Rigorous quality control and certifications ensure product reliability under diverse operating conditions. The inclusion of monitoring sensors and IoT-enabled control systems enhances operational transparency and predictive maintenance.

Industrial Water Treatment: Practical Insights and Diverse Applications

In my consultancy work spanning over a decade, applying optimized RO and filtration units enabled several clients in coastal petrochemical plants to reduce water-related operational costs by up to 25%. By integrating precise monitoring of feedwater temperature and salinity — particularly understanding the heat capacity of seawater — we tailored energy consumption during desalination processes, increasing system energy efficiency by approximately 15%. These improvements were grounded in fundamental thermodynamic data as detailed by Sharqawy et al. in their comprehensive study on seawater properties.

In another case, a remote island community depended on containerized desalination units combined with UV disinfection to secure potable water year-round despite variable seawater quality and temperature. The modular setup allowed for easy seasonal scaling and maintenance, resulting in a reliable supply that met stringent WHO standards.

Moreover, industrial boilers and cooling towers benefit from pre-treatment that stabilizes water hardness and temperature, mitigating scaling and corrosion — a lesson reinforced by my observations consulting for large manufacturing clients. While the precise heat capacity of seawater affects thermal system design, managing water chemistry to retain that capacity near ideal values is equally vital for sustaining heat transfer efficiency.

Summary

Industrial and commercial water treatment systems must balance performance, flexibility, and operational economy across various applications. Reverse osmosis membranes form the treatment foundation, supported by filtration and softening units. Containerized systems enhance deployment agility, while UV and other disinfection technologies ensure microbiological safety.

Understanding the thermal and physical properties of seawater — particularly the heat capacity of seawater — is essential for optimizing desalination and thermal management in industrial water treatment. Combining authoritative thermophysical data with field experience yields practical, energy-efficient solutions tailored to client-specific challenges.

Water treatment professionals and procurement specialists can thus leverage these insights to select equipment and design systems that uphold rigorous quality standards, adapt to operational demands, and deliver sustainable value.

Reference for Thermal Properties of Seawater

The fundamental thermophysical parameters, including specific heat capacity, density, and thermal conductivity of seawater as functions of temperature and salinity, have been comprehensively reviewed by Sharqawy, Lienhard V, and Zubair in “Thermophysical properties of seawater: A review of existing correlations and data”, published in Desalination and Water Treatment (April 2010). This authoritative study forms the basis for accurate thermal management in seawater treatment processes.