The demand for pristine water across industrial and commercial sectors isn’t merely a preference; it’s a fundamental necessity. From ensuring product integrity and operational efficiency to extending equipment lifespan and safeguarding public health, the quality of water directly impacts every facet of modern business. In an era marked by increasing water scarcity and escalating contamination concerns, finding reliable solutions for diverse water quality requirements has never been more critical. This is where the reverse osmosis water system emerges as a leading technology, offering an unparalleled capability to achieve exceptional water purity. This comprehensive article aims to guide you through the technical intricacies, vast applications, and diverse equipment options available for industrial and commercial water treatment. We’ll also highlight the expertise of industry leaders in delivering these essential solutions.

1. Understanding the Core Technology: How a Reverse Osmosis Water System Works

This section delves into the technical principles and components of a reverse osmosis water system, reinforcing its capability in producing pure water.

1.1 The Fundamentals of Reverse Osmosis

Osmosis is a natural phenomenon where water molecules move from an area of lower solute concentration to an area of higher solute concentration through a semi-permeable membrane. Reverse osmosis (RO) water treatment, conversely, leverages external pressure to counteract this natural flow. By applying pressure greater than the natural osmotic pressure to the side with higher solute concentration, water molecules are forced through the semi-permeable membrane, leaving behind dissolved solids and other impurities. This process is highly effective, making reverse osmosis water purification a cornerstone of modern water treatment strategies. The primary benefit lies in its ability to remove a vast spectrum of contaminants, ensuring exceptionally clean and pure water.

1.2 Essential Components of a Complete RO System

A comprehensive water treatment system isn’t just about the RO membrane; it involves several stages that work in concert to protect the membrane and maximize efficiency.

Here’s a breakdown of the critical components:

- Pre-treatment Systems: These are vital for removing larger particles and substances that could damage or foul the delicate RO membrane.

- Sediment Filters: The first line of defense in most water treatment systems, these remove visible particles like sand, silt, rust, and scale. They typically range from 5 to 20 microns.

- Activated Carbon Filters: These are crucial for adsorbing chlorine, chloramines, volatile organic compounds (VOCs), pesticides, and other chemicals that can damage RO membranes. They also improve the water’s taste and odor. Activated carbon in water treatment significantly prolongs membrane life.

- Water Softeners: For areas with hard water, these systems remove calcium and magnesium ions—the primary culprits of scaling. This hard water treatment is essential to prevent scale buildup on RO membranes, which can drastically reduce their efficiency and lifespan. Many water treatment for well water applications also benefit from softening due to high mineral content.

- High-Pressure Pump: This pump is indispensable for generating the significant pressure required to force water through the RO membrane, overcoming osmotic pressure.

- RO Membrane Module: The core technology of the reverse osmosis water system, consisting of one or more semi-permeable membranes. These are often thin-film composite (TFC) or thin-film membrane (TFM) elements, typically arranged in a spiral-wound configuration to maximize surface area.

- Post-treatment Systems (Optional but Recommended):

- UV Sterilization: An effective final step that uses ultraviolet-C (UV-C) light to inactivate or kill bacteria, viruses, and cysts. UV water treatment, particularly systems compliant with NSF/ANSI 55 standards, ensures microbiological safety without chemicals. UV light water treatment is a critical addition for producing potable water.

- Deionization (EDI/Mixed-Bed Resin): For applications demanding ultra-pure water, such as in laboratories or semiconductor manufacturing, Electro-Deionization (EDI) or mixed-bed resin tanks can further polish the water to extremely low conductivity levels. This is frequently used in industrial water treatment to achieve incredibly high purity.

- Brackish Water RO System: Designed to treat water with a higher total dissolved solids (TDS) content than tap water but less than seawater. These systems are crucial for industries and municipalities drawing from groundwater or less saline surface water sources. Typical applications range from factories needing process water to agricultural irrigation and small municipal water treatment plants.

- Seawater Desalination System: These are robust water treatment plants equipped with high-pressure pumps and specialized membranes capable of handling the extreme salinity of seawater. They are vital for coastal industries, island communities, marine vessels, and emergency water supplies where freshwater sources are scarce.

- Ultrafiltration (UF) System & Nanofiltration Systems: Often integrated into larger industrial water treatment setups, UF systems (0.01-0.1 micron pore size) effectively remove suspended solids, colloids, and bacteria, while nanofiltration systems (NF, less than 0.001 micron) can remove larger organic molecules and some multivalent ions, acting as an excellent pre-treatment for RO or as standalone contaminant removal.

- EDI Ultrapure Water System: Electro-Deionization (EDI) systems are employed to generate exceptionally pure water projects for high-tech and sensitive applications. These systems are critical in industries such as pharmaceuticals, medical facilities, cosmetics factories, laboratories, and electronics manufacturing, where water resistivity of 18.2 MΩ·cm is often required.

- Commercial RO Systems: These systems are perfectly suited for businesses requiring medium-scale outputs of purified water. Applications include hotels, restaurants, schools, government buildings, and small-scale bottled water production facilities. They are also widely used for drinking water treatment in public institutions and for food processing (e.g., beverage factories, seasoning factories, ice-making, breweries) where water quality directly impacts the final product.

- Household RO Systems: Bringing the benefits of reverse osmosis water system directly into homes, these units provide clean and safe drinking water for families, emphasizing ease of installation and maintenance. For many, a home water treatment system is an essential investment for health and peace of mind.

- Bottled Water Filling Production Line: For entrepreneurs or businesses looking to enter the bottled water market, integrated solutions encompassing the RO purification process and automated filling, capping, and labeling capabilities are available.

- Water treatment equipment wholesalers, agents, and accessory sellers: Providing reliable products for distribution.

- Clients for pure water and ultra-pure water projects: Including industries like urea production, hydrogen production, medical facilities, pharmaceutical plants, photovoltaic manufacturing, cosmetics factories, and laboratories, all requiring stringent pure water projects.

- Drinking water applications: From commercial RO machines and UF systems to household units and full filling lines, supporting food processing and daily drinking water for public institutions.

- Specialized industrial requirements: Catering to agriculture (plantation farms, animal husbandry), dyeing factories, and seawater desalination needs.

- Global cross-border e-commerce buyers: Making advanced water treatment accessible worldwide.

- Industrial Process Water: Critical for manufacturing across various industries, including electronics, automotive, textiles, and cleanroom applications in pharmaceuticals. It’s also vital for boiler feed water in power generation and in the petrochemical industry to prevent scaling and corrosion.

- Food and Beverage: Essential for process water in bottled water production, soft drinks, breweries, dairy operations, and ingredient preparation where water purity directly affects product safety and taste.

- Agriculture: High-purity irrigation for sensitive crops and purified drinking water for livestock (water treatment for well water is often key here) improve yields and animal health.

- Municipal & Emergency Use: Potable water production for communities, vital for disaster relief, and supplying remote site operations.

- Marine & Offshore: Seawater desalination on ships, oil rigs, and coastal facilities provides essential freshwater.

- Environmental: Used in wastewater treatment for reuse applications and reducing the environmental impact of industrial discharge.

- Input Water Quality: Analyze the TDS, hardness, and specific contaminants of your source water. This determines the necessary pre-treatment.

- Required Output Water Quality: Define the desired purity levels and specific contaminant removal needs for your application (e.g., potable, ultra-pure, process water).

- Flow Rate/Capacity: Calculate the gallons per day (GPD) or cubic meters per hour required to meet your operational demands.

- Budget: Consider both the initial investment and the ongoing operational costs, including maintenance and energy consumption.

- Footprint and Space Availability: Evaluate the physical space available for the system installation.

- Maintenance Requirements and Serviceability: Factor in ease of access for routine maintenance and filter/membrane replacements.

- Local Regulations and Standards: Ensure the chosen system complies with all relevant local and industry-specific water quality standards.

These combined elements ensure that a reverse osmosis water system delivers consistent, high-quality purified water, tailored to specific commercial or industrial needs.

2. Diverse RO System Architectures & Capabilities

This section details the multi-tiered product offerings, showcasing their adaptability to various industrial and commercial needs.

2.1 Industrial RO Water Purification Systems

Industrial-grade reverse osmosis water purification systems are engineered for large-scale operations, where consistent high purity and flow rates are paramount. Many modern industrial setups benefit from remote monitoring and control capabilities, enhancing efficiency and enabling predictive maintenance.

Types of industrial RO systems include:

2.2 Commercial & Household Water Purification Equipment

Beyond the heavy industrial scale, RO technology is scaled down to serve commercial and residential needs, providing safe and clean water for everyday use.

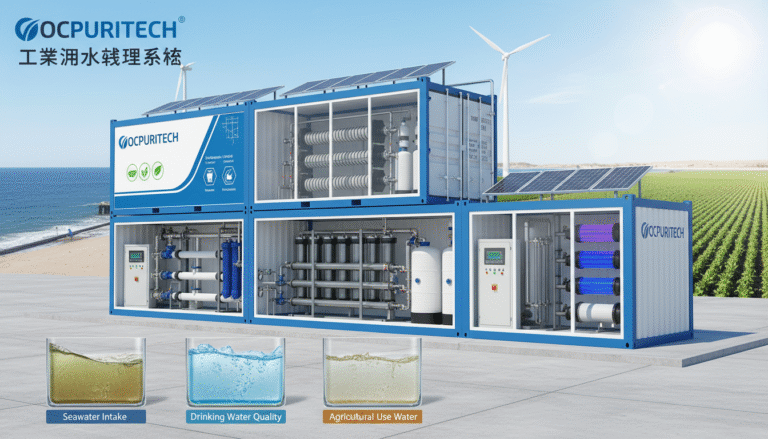

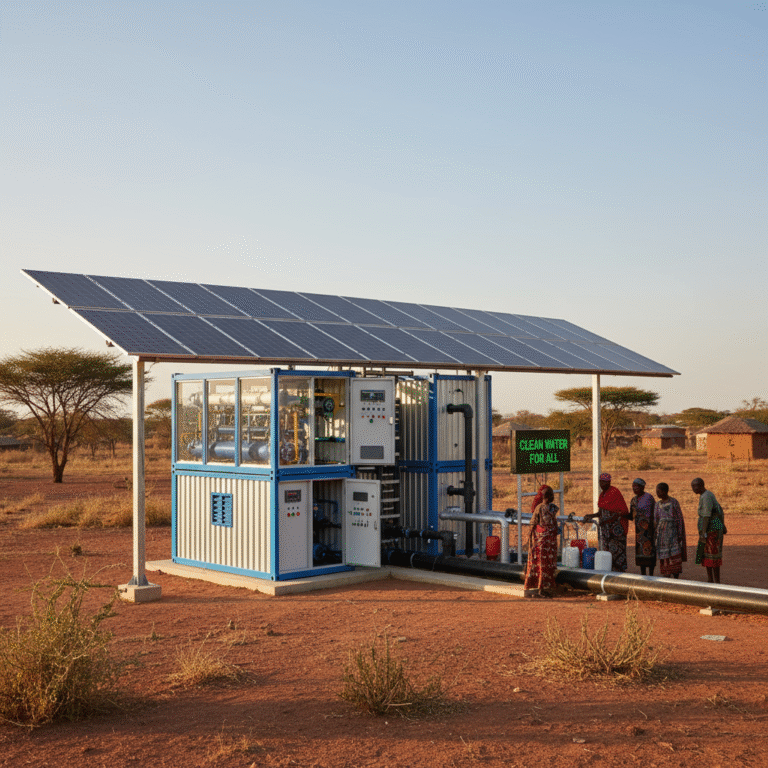

2.3 Containerized Systems: Portability and Rapid Deployment

Containerized water treatment plant systems represent a significant advancement in flexibility. These are complete, pre-assembled water treatment solutions housed within standard shipping containers, making them highly portable and deployable. Their advantages include rapid deployment, significantly reduced installation time on-site, and excellent mobility. This makes them ideal for remote locations, emergency relief operations, temporary construction projects, and even military camps.

3. Ocpuritech: A Legacy of Purity and Innovation

My experience in the field has shown that genuine expertise comes from years of dedicated focus. Ocpuritech exemplifies this, continuously refining what makes a reverse osmosis water system truly excellent.

3.1 Brand Heritage and Expertise

Established in 2011, Ocpuritech (Guangzhou Aomi Water Purification System Manufacture Co., Ltd.) boasts 14 years of dedicated experience in the water treatment industry. This extensive track record is supported by two standardized factories in Guangzhou and Jiangmen, totaling over 10,000 square meters, showcasing their robust manufacturing capability. Ocpuritech’s core business scope spans industrial, commercial, and household water purification, alongside complete filling lines. Our products are trusted and praised by customers from all over the world, a testament to their commitment to quality and service.

3.2 Commitment to Quality and R&D

Ocpuritech doesn’t just sell products; they deliver solutions built on a foundation of professional technology experience and sincere service. They provide high-quality and cost-effective water treatment products, ensuring that every client receives a system perfectly suited to their needs. From complete purification equipment to essential spare parts like filter cartridges, UV lamps, FRP tanks, carbon, flow meters, and filling machines, Ocpuritech ensures comprehensive support for the entire water treatment system. This commitment extends to a broader vision, as articulated by Mrs. Carrie Chan: “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.”

3.3 Tailored Solutions for Diverse Clientele

Ocpuritech serves a wide range of clients, demonstrating the versatility of their water treatment solutions:

Ocpuritech positions itself as a strategic partner, helping customers develop their businesses, whether for drinking and selling bottled water or for other critical purposes requiring purified water.

4. Practical Applications and Choosing the Right System

4.1 Diverse Case Studies and Applications

The versatility of the reverse osmosis water system means its applications span almost every sector. In my years, I’ve seen RO technology solve seemingly impossible water treatment challenges.

4.2 Factors to Consider When Selecting an RO System

Choosing the right reverse osmosis water system requires careful consideration of several factors:

The importance of effective water treatment in today’s industrial and commercial landscape cannot be overstated. The reverse osmosis water system stands as a powerful and versatile technology, capable of delivering pure water across a vast array of applications. Ocpuritech, with its 14 years of dedicated experience and a comprehensive range of high-quality, cost-effective solutions, is a trusted partner in this critical field. From large-scale industrial water treatment plants to customized commercial setups and robust containerized units, Ocpuritech’s commitment to customer success and environmental responsibility shines through.

Partner with Ocpuritech, a trusted leader in water purification, to secure your pure water future. We invite you to explore their solutions and contact them for a consultation, custom system design, or to inquire about their diverse product lines and spare parts and achieve pure water for your specific needs.

FAQ Section: Addressing Common Queries

Q1: What is a reverse osmosis water system and how does it compare to other water treatment methods?

A reverse osmosis water system uses pressure to force water through a semi-permeable membrane, removing dissolved solids and impurities. Unlike basic filtration (which removes particles) or chemical methods, RO offers a higher degree of purification, making it superior for removing a broad spectrum of contaminants from various water treatment systems.

Q2: How effective is reverse osmosis water treatment in removing contaminants?

Reverse osmosis water treatment is highly effective, capable of removing 95-99% of dissolved salts, particles, colloids, organics, bacteria, and pyrogens. This makes reverse osmosis water purification a top choice for producing high-purity water.

Q3: Can RO systems be used for well water treatment?

Yes, well water treatment frequently benefits from RO systems, especially if the well water contains high levels of minerals, dissolved solids, or specific contaminants. Adequate pre-treatment (like sediment filters and water softeners) is crucial to protect the RO membrane in well water treatment systems.

Q4: What are the key differences between industrial and commercial water treatment systems?

Industrial water treatment systems are generally much larger, designed for continuous high-volume output (thousands to millions of gallons per day), and often include complex pre- and post-treatment stages for highly specialized applications. Commercial water treatment systems are smaller in scale, serving businesses like restaurants or small factories, with capacities typically in the hundreds to thousands of gallons per day.

Q5: Do I need a water softener before my RO system?

If your source water has high hardness (high calcium and magnesium content), a hard water treatment like a water softener is highly recommended before an RO water treatment system. This prevents scaling on the RO membranes, which can severely reduce efficiency and lifespan.

Q6: What are the benefits of a whole house reverse osmosis water treatment system?

A whole house reverse osmosis water treatment system provides purified water to every tap in your home, ensuring clean water for drinking, bathing, and cooking. This offers comprehensive protection, though such systems are typically larger and more complex than point-of-use units, providing superior results compared to other home water treatment systems.

Q7: How often do RO membranes and filters need to be replaced?

The frequency of replacement for RO membranes and pre-filters depends on the quality of your source water and your usage. Generally, pre-filters (sediment and carbon) should be changed every 6-12 months, while RO membranes in water treatment equipment typically last 2-5 years.

Q8: What are the main applications of a seawater desalination system?

Seawater desalination systems are primarily used in coastal regions, island communities, on ships and offshore platforms, and in areas facing severe freshwater scarcity where they convert saline seawater into potable or process water.

Q9: Does Ocpuritech offer solutions for ultra-pure water applications like in pharmaceutical factories?

Yes, Ocpuritech specializes in pure water projects, including advanced EDI ultrapure water system solutions tailored for industries like pharmaceuticals, electronics, and laboratories that require extremely high water purity.

Q10: Where can I find reliable water treatment companies near me for installation and service?

For reliable professional installation and service, it’s best to consult with reputable water treatment companies near me directly. Many manufacturers, like Ocpuritech, have networks of authorized dealers and provide direct consultation for their water treatment services near me.