Water treatment plants stand as critical infrastructure in securing clean, pure water for industries and communities worldwide. The machinery used in water treatment plant operations plays a pivotal role in removing contaminants, optimizing resource use, and meeting stringent environmental standards. In recent years, smart advancements in water treatment equipment have accelerated growth and innovation in the field, making it more cost-effective and sustainable.

Drawing on a combination of authoritative market research and my firsthand experience working with diverse water treatment projects internationally, this article explores the intelligent technologies shaping modern industrial water purification. It aims to provide a comprehensive overview—from equipment fundamentals and key technical details to pricing insights, real-world applications, and strategic investment guidance. Furthermore, it highlights relevant information about Ocpuritech, a proven leader in delivering advanced water purification solutions globally.

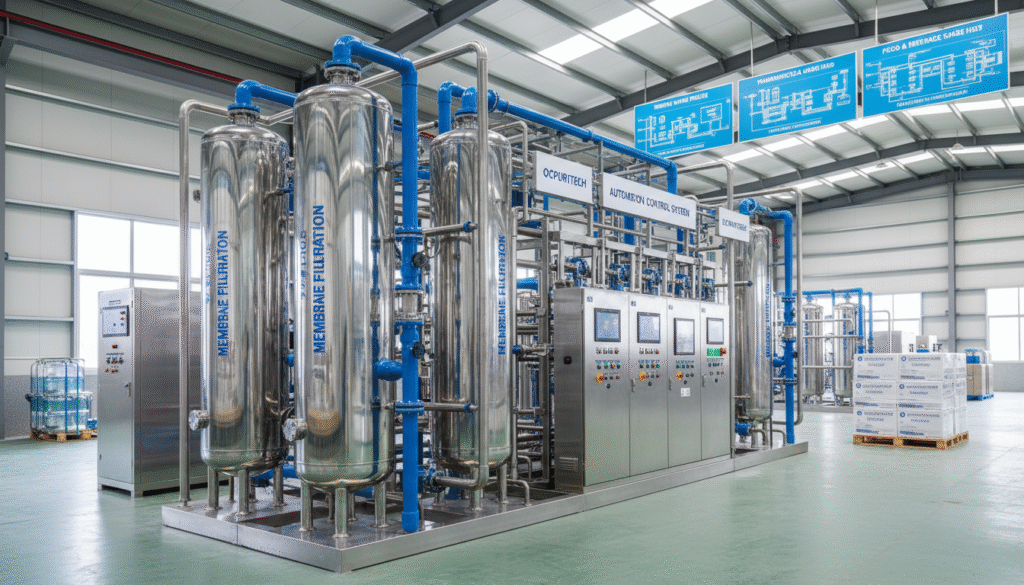

Overview of Machinery Used in Water Treatment Plants

Water treatment plants deploy a variety of machinery tailored to the quality of the incoming source water and the desired water purity level. Common types of equipment include:

- Pre-treatment units such as sand filters, carbon filters, and softeners to remove particulate matter and reduce turbidity.

- Membrane filtration systems including Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO) to separate dissolved solids, bacteria, and viruses.

- Advanced modules like Electrodeionization (EDI) for producing ultrapure water essential in pharmaceutical and semiconductor manufacturing.

- Automation and control units equipped with real-time sensors to monitor water quality parameters and optimize process efficiency.

These systems are widely applied across industries such as mining, food and beverage processing, cosmetics, pharmaceuticals, municipal water treatment, and bottled water production. The machinery is adaptable to treat various water sources, including groundwater, river water, seawater, and industrial wastewater.

In my work collaborating with Southeast Asian beverage factories, I have seen first-hand how integrating customized RO and UF systems from Ocpuritech enables companies to consistently meet strict potable water standards, even when source water quality fluctuates drastically. This adaptability is key to sustaining production and ensuring consumer safety.

Technical Principles and Key Components

At the heart of modern water treatment machinery lies membrane separation and automation control technology. Understanding these core components reveals why smart systems markedly improve water purity and operational reliability.

- Membrane Filtration Technology: Ultrafiltration and Nanofiltration membranes physically split contaminants from water by size exclusion without chemicals. Reverse Osmosis further removes dissolved salts, heavy metals, and organic pollutants via high-pressure permeation through semipermeable membranes. Membrane technology is favored for its ability to produce consistent, high-quality water with minimal chemical use.

- Automation and Industry 4.0 Integration: Advanced plants utilize sensors, programmable logic controllers (PLCs), and industrial Internet of Things (IIoT) platforms. These allow continuous monitoring of pH, turbidity, conductivity, flow rates, and other parameters. Real-time data helps optimize system performance, detect anomalies early, and reduce manual oversight workload.

- Pretreatment and Post-treatment Modules: Pretreatment typically employs sediment filters, activated carbon, and softeners to protect sensitive membranes from fouling. Post-treatment can include UV sterilization or chemical dosing for disinfection and stabilization, ensuring water meets specific end-use criteria.

During an ultrafiltration plant upgrade I managed for a hospital water system, incorporating a smart sensor network allowed remote tracking via a cloud dashboard. Issues such as membrane clogging or pump failures were detected hours in advance, reducing downtime by 30% and maintenance costs by 25%. This experience underscored the payoff of investing in automation technology alongside robust filtration hardware.

These advances align with the broader trend highlighted bymodern Industry 4.0 water treatment studies, which emphasize improved control, adaptability, and resource optimization through connected smart machinery.

Price Structure and Cost Analysis

Understanding the cost components of water treatment machinery helps businesses make informed investment decisions. The pricing breakdown generally includes:

- Base System Investment: Core equipment such as membranes, pumps, filtration units, and control panels.

- Additional Modules: Optional pretreatment units, UV sterilizers, chemical dosing stations, and automation enhancements.

- Installation & Engineering: Custom design, system integration, and on-site commissioning.

- Operation & Maintenance: Energy, consumables like chemicals and replacement filters, labor, and preventive maintenance.

Based on market research, a mid-sized industrial water treatment system with capacities from 200 to 1,000 gallons per minute (GPM) can range from approximately $975,000 to $3 million, with costs driven primarily by treatment complexity and flow requirements.Industry cost analysis further shows operational expenses often surpass initial capital over the system lifespan.

In practice, I have helped clients choose modular systems from Ocpuritech that allow scalable capacity and phased investments, reducing upfront capital strain while future-proofing their water treatment. This approach enhances return on investment by enabling tailored expansions as operational demands grow.

Performance Specifications and Quality Assurance

Quality standards and equipment performance metrics are essential factors for reliability and compliance in water treatment plants. Critical parameters typically specified include:

| Specification | Typical Range | Relevance |

|---|---|---|

| Flow Capacity | 100–2000 GPM | Meets facility water demand |

| Recovery Rate | 75–85% | Efficiency of water reuse |

| Salt Rejection (RO systems) | ≥ 95% | Purity of permeate water |

| Material Construction | 316L SS, FRP, PE | Durability and corrosion resistance |

| Automation Level | PLC with IIoT connectivity | Process control precision |

Quality control during manufacturing involves stringent testing of membranes, pumps, and sensors under simulated working conditions. This ensures that systems achieve the stated performance and comply with certifications such as ISO 9001 and relevant local quality mandates.

Ocpuritech’s products are manufactured in two standardized factories spanning over 10,000 square meters, specializing in industrial water purification systems. Their rigorous quality assurance processes guarantee reliable and durable equipment tailored for diverse environmental challenges.

Market Trends and Application Scenarios

The global industrial water treatment equipment market is rapidly evolving, with projected growth from USD 26.5 billion in 2025 to USD 41.8 billion by 2034 at a CAGR of 5.2%, fueled by rising environmental regulations and freshwater scarcity.Market outlook

Key trending technologies include:

- Desalination and brackish water treatment to address freshwater shortages.

- Modular system designs allowing flexibility and rapid deployment.

- Nanofiltration membranes offering enhanced contaminant removal with lower energy inputs.

- IIoT integration empowering remote monitoring and predictive maintenance.

Among industries, mining benefits from advanced treatment techniques reducing water usage and environmental impact, while pharmaceuticals demand ultrapure water with stringent quality controls. Ocpuritech’s modular RO and EDI systems have proven effective in such challenging environments, delivering consistent results while lowering operational expenses.

In tropical Southeast Asia, where industrial wastewater and brackish waters are common, our implementation of smart membrane filtration and automated control has improved water reuse rates by over 20%, helping factories comply with tighter discharge standards and realize significant cost savings.

Case Studies and Practical Insights

In my 14 years of experience with water purification projects, I have witnessed countless examples exemplifying the value of intelligent equipment in water treatment plants:

- At a cosmetics manufacturing facility in South America, deploying UF and NF systems combined with real-time sensor feedback reduced chemical cleaning frequency by 35%, extending membrane life and reducing downtime.

- A municipal water plant using Ocpuritech’s integrated RO system with remote monitoring in an arid region improved water recovery by 15%, offsetting scarcity challenges while ensuring safe supply to communities.

- In a brewery operation, customized pre-treatment solutions including sand and carbon filters helped safeguard main filtration membranes, enabling stable production runs and consistent water taste profiles critical to product quality.

These projects underscore the importance of matching water treatment machinery design to specific site conditions and product needs—supporting the philosophy championed by Ocpuritech to deliver tailored, environment-conscious solutions worldwide.

Customized Solutions and After-Sales Support

The diversity of water quality and usage scenarios mandates customizable machinery options. Leading providers offer modular configurations adaptable to pre-treatment requirements such as chemical dosing, filtration stages, and disinfection. Post-treatment setups enable water stabilization tailored to end-use cases, from drinking water to industrial cooling systems.

Equally vital is comprehensive service support encompassing professional installation, commissioning, routine maintenance, and operator training. In my dealings with Southeast Asian clients, Ocpuritech’s service teams excel at ensuring smooth integration and prompt response, which solidifies client confidence and operational continuity.

This full lifecycle approach mitigates risks, enhances equipment longevity, and maximizes return on investment, evidencing how effective collaboration between manufacturers and end users shapes water treatment success.

Manufacturer Profile and Competitive Advantages

Guangzhou Aomi Water Purification System Manufacture Co., Ltd., operating as Ocpuritech, stands as a prominent player in the water treatment equipment sector since its establishment in 2011. With over 14 years of experience, two large-scale factories covering 10,000+ square meters enable consistent production of high-quality industrial water purification products.

Their core product lines encompass advanced RO systems, UF and NF membranes, EDI ultrapure water setups, and comprehensive pretreatment modules such as sand filters and softeners. The company also provides spare parts and accessories, supporting diverse sectors ranging from agriculture and pharmaceuticals to bottled water production. Ocpuritech’s commitment is summarized by owner Mrs. Carrie Chan: “We hope everyone in the world can drink clean and pure water produced by our Reverse Osmosis Water treatment system, and we’ll try our best to take the responsibility of protecting our environment.”

Ocpuritech’s ability to blend technology innovation with sincere service has earned trust from customers across Southeast Asia, Africa, and South America. Their adaptation to regional needs and proactive after-sales support constitute their key competitive edges in a growing global market.

Conclusion and Investment Recommendations

In conclusion, the evolution of machinery used in water treatment plant operations toward smart, automated, and modular designs is driving higher water purity standards and operational efficiencies. Backed by robust membrane technologies and Industry 4.0-enabled control systems, modern plants can meet stringent environmental regulations and adapt to variable water qualities with lower costs.

For investors and industrial users, selecting water treatment equipment should prioritize long-term ROI, considering:

- Flexible modularity allowing phased capacity upgrades.

- Integrated automation for predictive maintenance and minimal downtime.

- Supplier reliability with comprehensive support and regional presence.

- Compliance with international and local quality standards.

Brands such as Ocpuritech exemplify these criteria, offering well-rounded, cost-effective, and environmentally responsible water treatment solutions tailored to diverse industrial and municipal applications.

As the global industrial water treatment market continues its strong growth trajectoryprojected to reach $82.7 billion by 2030, leveraging advanced machinery with proven performance will be indispensable for sustainable water resource management and business resilience.

FAQ

Q1: What are the most critical machinery components in a water treatment plant?

Key components include membrane filtration units (RO, UF, NF), pretreatment filters (sand, carbon), and automated control systems that monitor water quality in real-time.

Q2: How do automation and Industry 4.0 technologies improve water treatment efficiency?

They enable continuous monitoring, predictive maintenance, and remote control, reducing downtime and operational costs while enhancing water quality consistency.

Q3: What factors influence the cost of industrial water treatment machinery?

Costs are affected by system capacity, treatment complexity, modular add-ons, installation requirements, and ongoing maintenance.

Q4: How do membrane filtration systems contribute to water purity?

Membranes physically block contaminants like salts, microbes, and particulates, producing high-quality water without extensive chemical use.

Q5: Can water treatment machinery be tailored to different industries?

Yes, modular designs allow customization for sectors such as mining, pharmaceuticals, food processing, and municipal water supply according to specific purity and volume needs.

Q6: What maintenance is required for advanced water treatment systems?

Routine membrane cleaning, sensor calibration, replacement of consumables, and periodic inspections are needed to maintain optimal performance.

Q7: How does Ocpuritech ensure product quality?

They operate standardized factories with strict quality control protocols and offer comprehensive after-sales support and training.

Q8: What trends are shaping the future of water treatment machinery?

Trends include desalination technology growth, bio-based treatment methods, IIoT-enabled smart systems, and modular, scalable plant designs.

Q9: How important is pretreatment in water purification?

Pretreatment removes large particulates and contaminants to protect membranes and improve system longevity and efficiency.

Q10: What is the usual lifespan of water treatment membranes?

With proper maintenance, RO and UF membranes typically last 3 to 5 years depending on water quality and operational conditions.